coating composition

A composition and coating technology, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of insufficient retouching, poor coating workability, insufficient weather resistance and hydrolysis resistance, etc. , to achieve the effect of excellent adhesion, excellent weather resistance, chemical resistance and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The polyol component used for the preparation of the hydroxyl group-containing polyester resin (B) may consist of only the cyclic polyol compound (b1), or may consist of the cyclic polyol compound (b1) and other polyols.

[0077] As other polyols other than the cyclic polyol compound (b1), for example, ethylene glycol, diethylene glycol, propylene glycol, dipropylene glycol, butylene glycol, neopentyl glycol, 1,2- or 1 , 3-propanediol, 1,6-hexanediol, 1,4-dimethylolcyclohexane, dipropylene glycol, butanediol, pentanediol, hexanediol, cyclohexanedimethanol, bis(hydroxymethyl base) dihydric alcohols such as xylene; glycerin, 1,1,1-trimethylolpropane, 1,2,3-butanetriol, pentaerythritol, dipentaerythritol and other alcohols with more than three valences. In addition, a hydroxyl group-containing modified oligomer formed by subjecting a polyol having two or more hydroxyl groups in one molecule to a lactone and undergoing a ring-opening esterification reaction can also be used...

manufacture example 1

[0146] (Production example 1) Production of hydroxyl-containing acrylic resin (A-1)

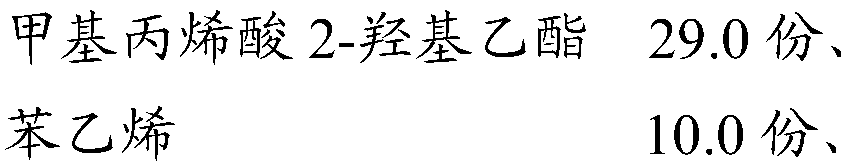

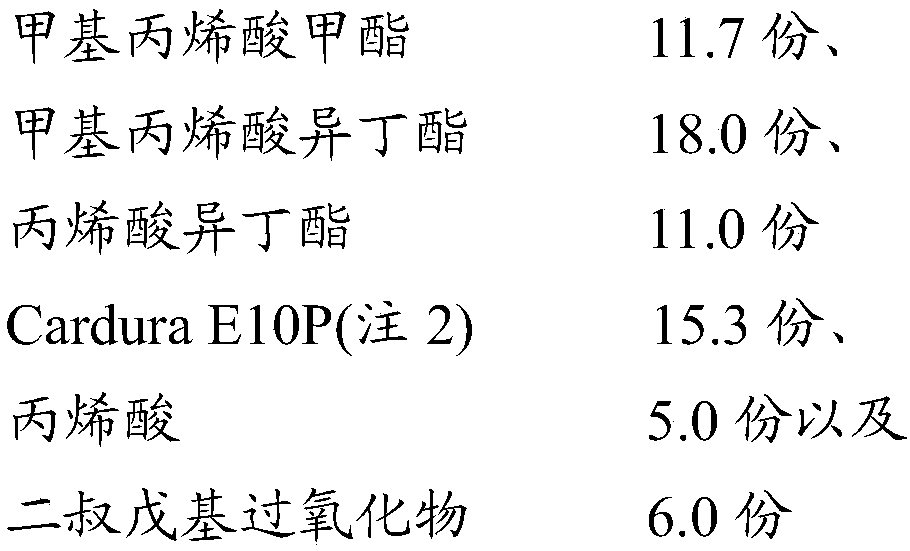

[0147] Put 60 parts of SWASOLE 1000 (Note 1) in a reaction vessel equipped with a stirring device, a thermometer, a reflux condenser, a thermostat, and a pump for dropping, and raise the temperature to 145°C while blowing in nitrogen gas and stirring, and use the pump for dropping Add the following monomers and polymerization initiator dropwise to the reaction vessel at a certain speed for 3 hours

[0148]

[0149]

[0150] mixture. Then, a mixture of 0.5 parts of di-tert-amyl peroxide and 10.0 parts of SWASOLE 1000 was added dropwise over 1 hour. After the dropwise addition was completed, the mixture was aged at the same temperature for 3 hours to complete the reaction. The obtained solution of the hydroxyl-containing acrylic resin (A-1) was a uniform transparent solution with a solid content of 60%. Moreover, the weight average molecular weight of resin (A-1) was about 4700, the gl...

manufacture example 2 to 5

[0153] (Production Examples 2 to 5) Production of Hydroxyl-containing Acrylic Resins (A-2) to (A-5)

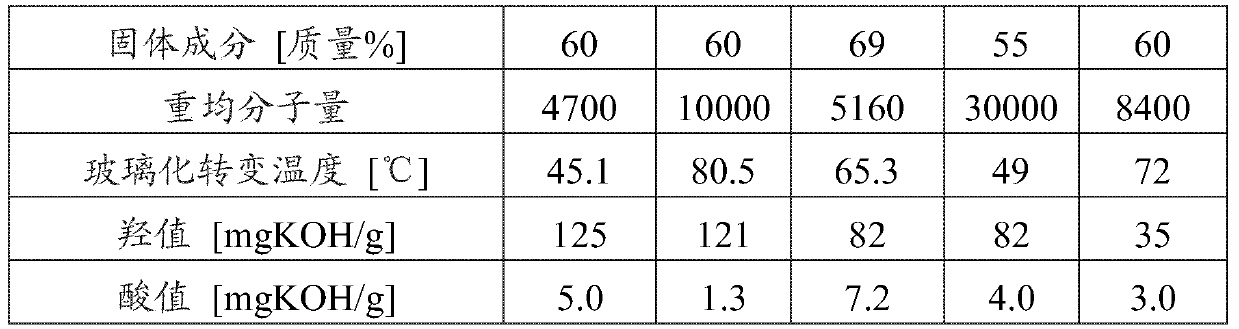

[0154] In manufacture example 1, except having mixed it according to the compounding of Table 1, it carried out similarly to manufacture example 1, and obtained the solution of hydroxyl-containing acrylic resin (A-2) - (A-5). Table 1 shows the solid content, weight average molecular weight, glass transition point temperature, hydroxyl value, and acid value of the obtained hydroxyl group-containing acrylic resins (A-2) to (A-5).

[0155] [Table 1]

[0156]

[0157]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com