A kind of preparation method of polymerizable organic amine cationic hydration shale inhibitor

A hydration inhibitor and cation technology, applied in the field of preparation of organic compounds, can solve the problems of large odor, insignificant effect, easy degradation, etc., and achieve the effects of mild reaction conditions, good inhibition effect and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

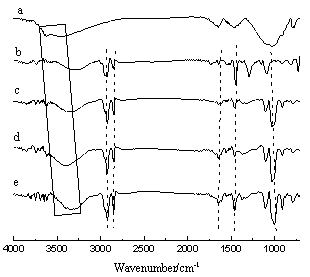

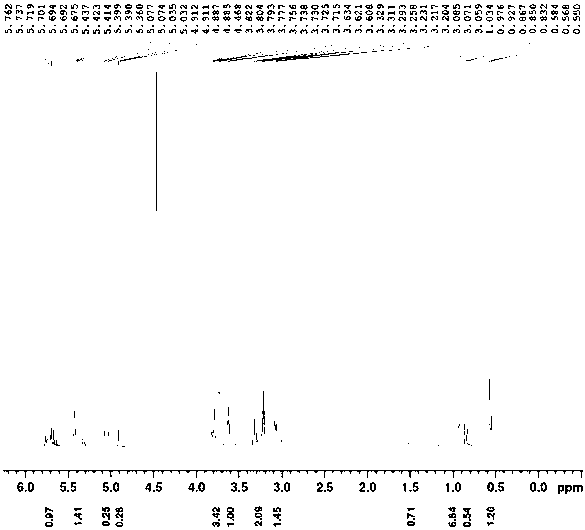

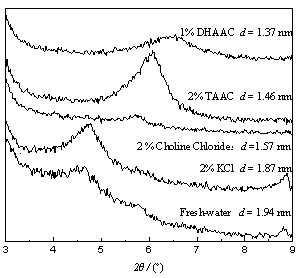

Method used

Image

Examples

Embodiment 1

[0035] Example 1: The preparation method of dodecyl dihydroxyethyl allyl ammonium bromide includes the following steps:

[0036] S1. Formation of tertiary amine intermediate dodecyldiethanolamine: After diethanolamine is dissolved in methanol, the temperature is raised to 75°C under a nitrogen atmosphere, and bromododecane is added dropwise to reflux reaction for 45h. The molar mass ratio of dioxane to diethanolamine is 1:1. After the reaction is over, add anhydrous sodium carbonate to the reaction solution, continue the reaction for 4.5 hours, heat to distill the alcohol, and add deionized water and anhydrous ether to the crude product After extraction, the ether layer was dried with anhydrous magnesium sulfate and distilled under reduced pressure to obtain the tertiary amine intermediate dodecyl diethanolamine. The molar mass ratio of the diethanolamine to anhydrous sodium carbonate was 1:0.8, deionized water and The volume ratio of water to ether is 1:1.2;

[0037] S2. The form...

Embodiment 2

[0038] Example 2: The preparation method of dodecyl dihydroxyethyl allyl ammonium bromide includes the following steps:

[0039] S1. Formation of tertiary amine intermediate dodecyl diethanolamine: After diethanolamine is dissolved in ethanol, the temperature is raised to 80°C under a nitrogen atmosphere, and bromododecane is added dropwise for reflux reaction for 48 hours. The molar mass ratio of dioxane to diethanolamine is 1:3. After the reaction is over, add anhydrous sodium carbonate to the reaction solution, continue the reaction for 5.5h, heat to distill the alcohol, and add deionized water and anhydrous ether to the crude product For extraction, the ether layer was dried with anhydrous magnesium sulfate and distilled under reduced pressure to obtain the tertiary amine intermediate dodecyl diethanolamine. The molar mass ratio of the diethanolamine to anhydrous sodium carbonate was 1:1.2, deionized water and The volume ratio of water to ether is 1:1.8;

[0040] S2. The forma...

Embodiment 3

[0041] Example 3: The preparation method of dodecyl dihydroxyethyl allyl ammonium bromide includes the following steps:

[0042] S1. Formation of tertiary amine intermediate dodecyldiethanolamine: After diethanolamine is dissolved in isopropanol, the temperature is raised to 76°C under a nitrogen atmosphere, and bromododecane is added dropwise to reflux for 46h. The bromine The molar mass ratio of dodecane and diethanolamine is 1:1.8. After the reaction is over, add anhydrous sodium carbonate to the reaction solution, continue the reaction for 5 hours, heat to distill the alcohol, and add deionized water and anhydrous to the crude product Ether was extracted, the ether layer was dried with anhydrous magnesium sulfate and distilled under reduced pressure to obtain the tertiary amine intermediate dodecyl diethanolamine, the molar mass ratio of the diethanolamine to anhydrous sodium carbonate was 1:1, deionized water and The volume ratio of anhydrous ether is 1:1.4;

[0043] S2. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com