Formaldehyde fluorescence probe and preparation method and application thereof

A fluorescent probe and formaldehyde technology, applied in the direction of fluorescence/phosphorescence, chemical instruments and methods, luminescent materials, etc., can solve the problems of limited detection sensitivity, destructive biological samples, etc., achieve high yield, realize detection, and achieve specificity and the effect of rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Synthesis of Compound 1:

[0055] ;

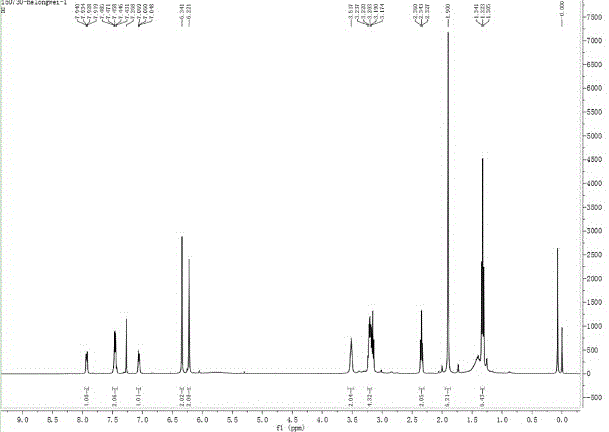

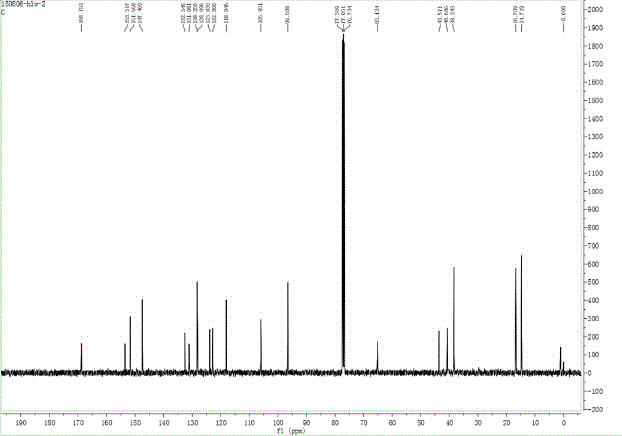

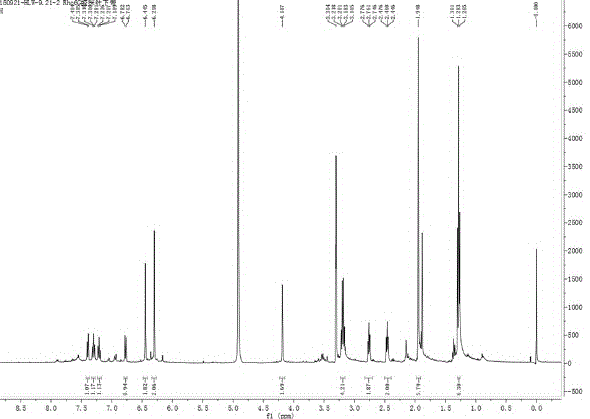

[0056] 480mg rhodamine 6G (molecular formula: C 28 h 31 N 2 o 3 Cl) (1.0mmol) was dissolved in methanol, then 300mg of ethylenediamine (5.0mmol) was added dropwise, the reaction solution was heated to about 70°C, and the temperature was kept constant after some substances began to reflux, and the reaction was stirred for 6 hours, and the reaction was completed. After the reaction was completed, the solvent (methanol) was removed by distillation under reduced pressure with a rotary evaporator to obtain a crude product. Using dichloromethane and ethanol at a volume ratio of 3:1 as the eluent, the silica gel (200-300 mesh) chromatography column was used for purification to obtain 342 mg of a white solid (yield 75%). 1 HNMR (400MHz, CDCl 3 ),(ppm):1.31-1.34(t,J=7.2Hz,6H),1.90(s,6H),2.33-2.35(t,J=6.6Hz,2H),3.17-3.24(m,4H), 3.52(3H),6.22(s,2H),6.34(s,2H),7.05-7.07(1H),7.43-7.49(m,2H),7.92-7.94(1H); 13 CNMR (100MHz, CDCl 3 ): δ(pp...

Embodiment 2

[0060] Fluorescence spectrum changes of embodiment 2 probe II reacting with different equivalents of formaldehyde

[0061] Dissolve the probe II prepared in Example 1 in DMF to make a probe mother solution with a concentration of 0.5mmol / L (the concentration of probe II is 0.5mmol / L); add the formaldehyde solution with a mass fraction of 37% into distilled water, Formaldehyde mother liquor that formaldehyde concentration is 1mmol / L is prepared. Take 60μL from the probe mother solution and add it to a 5mL centrifuge tube, add different equivalents (0-2eq) of formaldehyde mother solution (the equivalent is the number of moles of formaldehyde in the mother solution of formaldehyde relative to the number of moles of probes in the mother solution of probe) Multiples of ), diluted to 3mL with 1.44mL DMF and different volumes of PBS aqueous solution (concentration 25mmol / L, pH 7.4), and configured as a test solution with a probe concentration of 10μmol / L and 50% DMF. Use a fluoresce...

Embodiment 3

[0062] Example 3 Fluorescence Changes of Probe II and Formaldehyde Over Time

[0063] Take 60 μL from the fluorescent probe mother solution in Example 2 and add it to a 5mL centrifuge tube, add 60 μL of formaldehyde mother solution with a concentration of 0.5mmol / L, then 1.44mL of DMF and 1.44mL of PBS aqueous solution (concentration 25mmol / L, pH7.4 ) was diluted to 3 mL, and prepared into a test solution with a probe concentration of 10 μmol / L, a formaldehyde concentration of 3 mmol / L, and 50% DMF. With an excitation wavelength of 530nm, its fluorescence spectrum changing with time was tested. Depend on Figure 7 It can be seen that as time increases, the fluorescence intensity at 560 nm gradually increases, and reaches the maximum value in about 10 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com