Modified lithium nickel cobalt manganese oxide cathode material and preparation method thereof

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problem of electrochemical properties such as cycle performance and stability, and limit the large-scale commercial application of materials. Reduced cycle life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The invention provides a method for preparing a modified nickel-cobalt lithium manganese oxide positive electrode material, which is characterized in that it comprises the following steps:

[0055] 1) reacting nickel cobalt lithium manganate material, manganese nitrate and phosphoric acid in an organic solvent to obtain a composite material in which the surface of the nickel cobalt lithium manganate material is compounded with manganese phosphate;

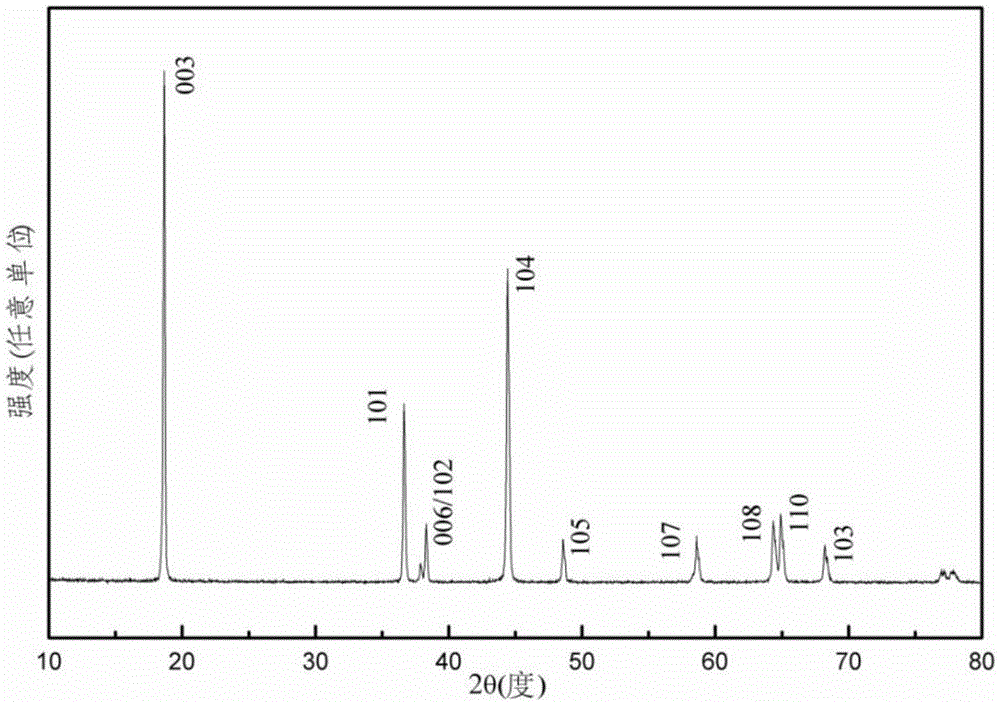

[0056] The chemical formula of described nickel cobalt lithium manganate material is as shown in formula (I),

[0057] LiNi 1-x-y co x mn y o 2 (1); Wherein, x>0, y>0, 1>1-x-y>0;

[0058] 2) Mix the composite material, lithium source and graphene obtained in the above steps in a solvent, and then calcinate to obtain a modified nickel-cobalt-lithium-manganese-oxide positive electrode material.

[0059] In the present invention, the selection and ratio of the raw materials and other optimization principles are the same as...

Embodiment 1

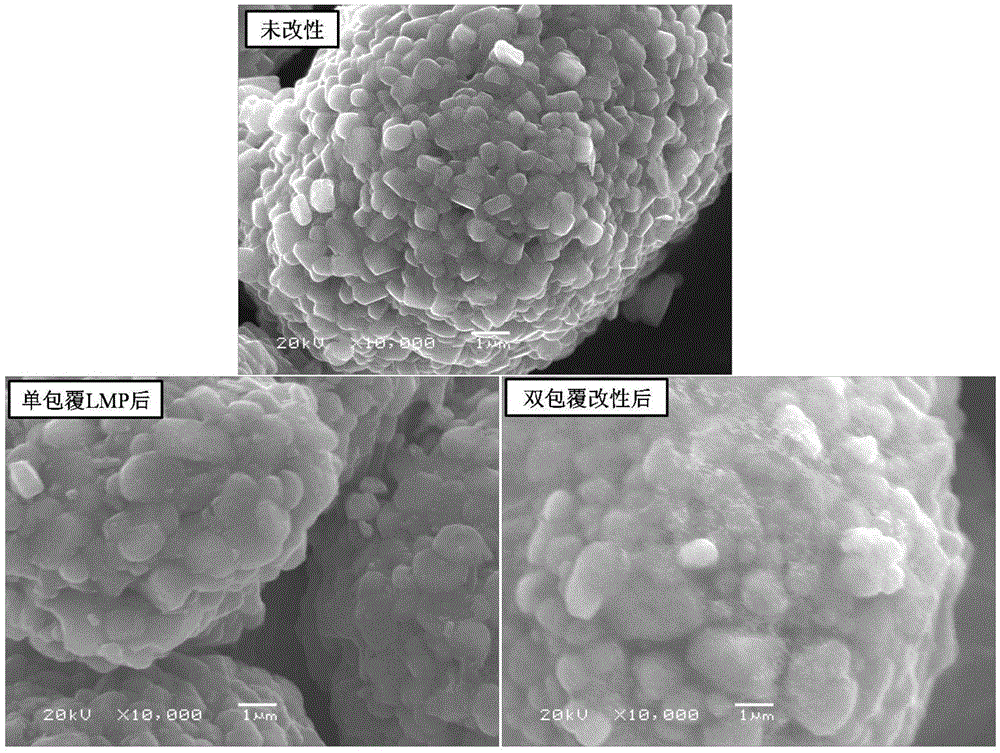

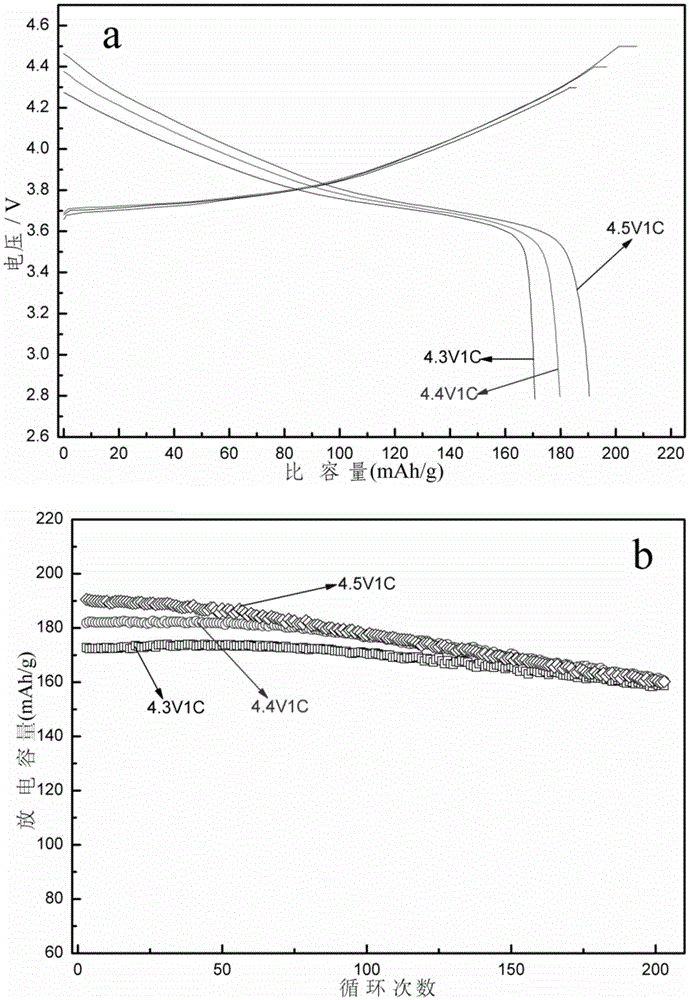

[0081] Commercialized LiNi 0.6 co 0.2 mn 0.2 o 2 Materials The positive electrode material is added to absolute ethanol. The mass ratio of the positive electrode material to absolute ethanol is 1:3. After stirring and dispersing at a high speed, manganese nitrate and phosphoric acid are added in sequence, and the addition amount is according to LiMnPO 4 with LiNi 1-x-y co x mn y o 2 The mass ratio of 0.01:1 is calculated separately, the reaction temperature of the control system is 60°C, and the stirring speed is 400r / min. After the reaction is completed, it is filtered and dried to obtain MnPO 4 ·H 2 O uniformly coated nickel-cobalt lithium manganate cathode material;

[0082] The nickel-cobalt lithium manganese oxide positive electrode material obtained above is fully mixed with lithium source and graphene in deionized water medium, and the addition amount of its graphene is the same as that of LiNi 1-x-y co x mn y o 2 The mass ratio is 0.005:1, placed in a nitro...

Embodiment 2

[0090] Commercialized LiNi 0.5 co 0.2 mn 0.3 o 2 The positive electrode material is added to absolute ethanol, and the mass ratio of positive electrode material to absolute ethanol is 1:4. After stirring and dispersing at high speed, manganese nitrate and phosphoric acid are added in sequence, and the addition amount is according to LiMnPO 4 with LiNi 1-x-y co x mn y o 2The mass ratio of 0.02:1 is calculated separately, the reaction temperature of the control system is 70°C, the stirring speed is 500r / min, after the reaction is completed, it is filtered and dried to obtain MnPO 4 ·H 2 O uniformly coated nickel-cobalt lithium manganate cathode material;

[0091] The nickel-cobalt lithium manganese oxide positive electrode material obtained above is fully mixed with lithium source and graphene in anhydrous ethanol medium, and the addition amount of its graphene is the same as that of LiNi 1-x-y co x mn y o 2 The mass ratio is 0.01:1, placed in an argon atmosphere, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com