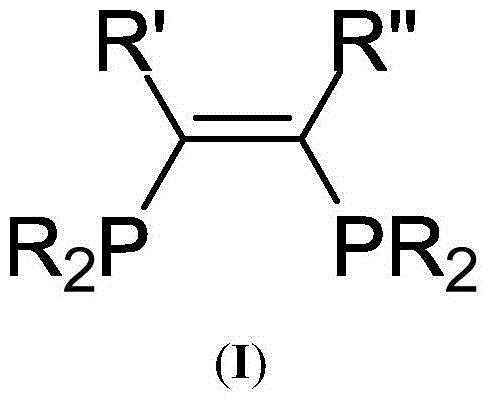

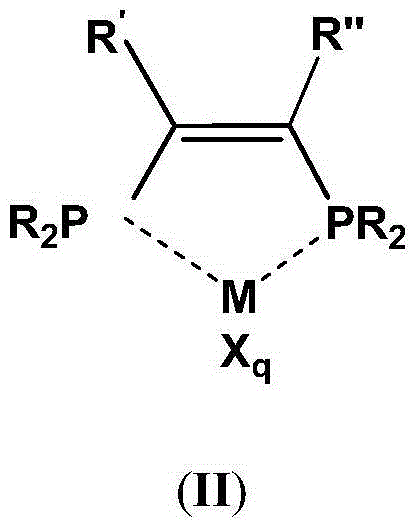

Ethylene oligomerization catalyst composition and applications thereof

A technology for ethylene oligomerization and composition, applied to a novel catalyst composition and its application field in ethylene oligomerization, can solve the problem of polymerization reaction process reaction initiation and poor repeatability, unfavorable ethylene oligomerization reaction process, and modified MMAO price. Expensive and other problems, to achieve the effect of ultra-high polymerization activity, rapid reaction initiation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

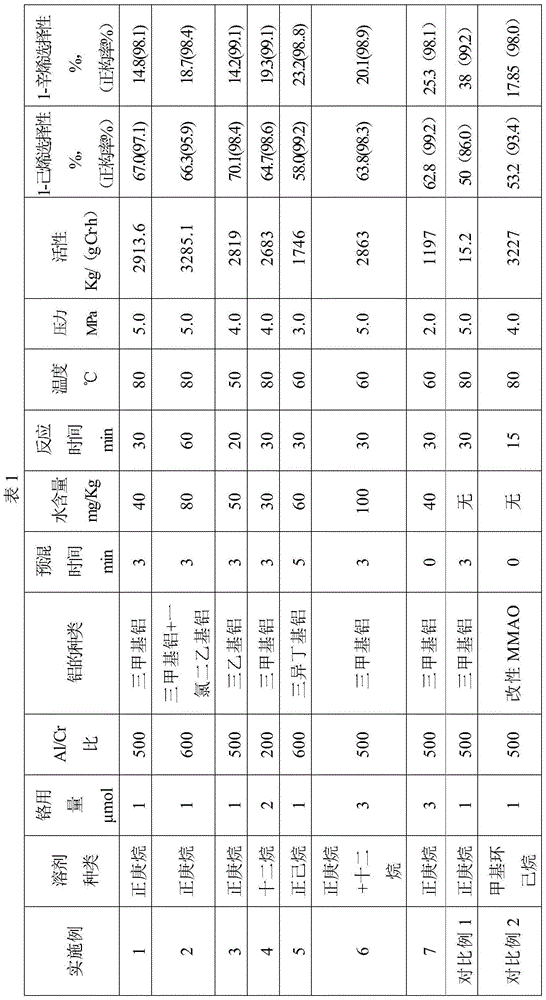

Embodiment 1

[0033] The polymerization reaction adopts a 500ml stainless steel polymerization kettle. First, the pressure-holding test was carried out on the reactor. Under the condition that the seal of the reactor was confirmed, it was vacuum-dried at 120°C for 4 hours, and then the temperature was lowered to 80°C and replaced with ethylene gas three times. Add solvent n-heptane, 500 equivalents of trimethylaluminum and water to the reaction kettle, start stirring and premixing for 3 minutes, then add a chromium complex solution containing 1 μmol of chromium to the reaction kettle until the reaction volume is 100ml, and the water content It is 40mg / Kg. Start stirring, open the ethylene feed valve, maintain the reaction pressure at 5.0 MPa, initiate the reaction, and stop the reaction after 30 minutes. After the test, the pressure was released to normal pressure, and the kettle was opened. After weighing the reaction solution, 1.5 mL of internal standard nonane was added, and the reacti...

Embodiment 2

[0037] The specific steps are the same as in Example 1, except that the cocatalyst is a mixed solution of 300 equivalents of trimethylaluminum and 300 equivalents of diethylaluminum chloride, the Al / Cr ratio is 600, and the water content is 80 mg / Kg. for 1 hour. The results of ethylene oligomerization are shown in Table 1.

Embodiment 3

[0039] The specific steps are the same as in Example 1, the cocatalyst is triethylaluminum, the Al / Cr ratio is 500, the reaction temperature is 50° C., the pressure is 4.0 MPa, the water content is 50 mg / Kg, and the reaction time is 20 minutes. The results of ethylene oligomerization are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com