Organic non-volatile memory device based on high K materials and preparation method thereof

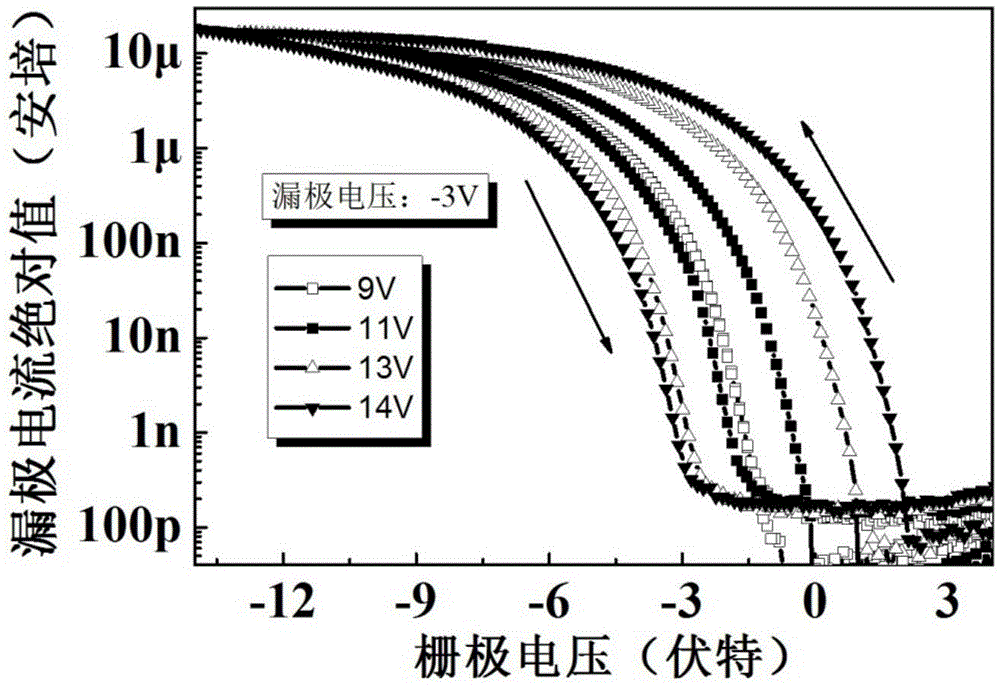

A non-volatile and memory device technology, applied in the field of organic non-volatile memory devices and their preparation, can solve the problems of poor long-term retention characteristics, slow flipping speed, high working voltage, etc., and achieve good device design ideas , low working voltage and small pulse width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

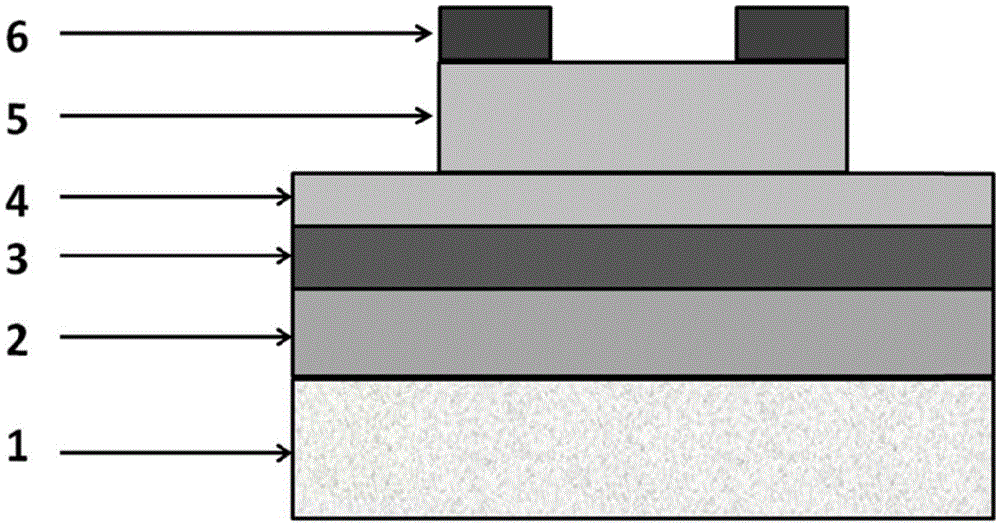

[0044] The preparation method of the organic non-volatile storage device based on the high-K material of the present invention comprises the following steps:

[0045] 1. Substrate cleaning: Select a heavily doped P(100) silicon wafer, first clean it by wet chemical method, and then use diluted hydrofluoric acid (0.1% volume concentration) to remove surface oxides.

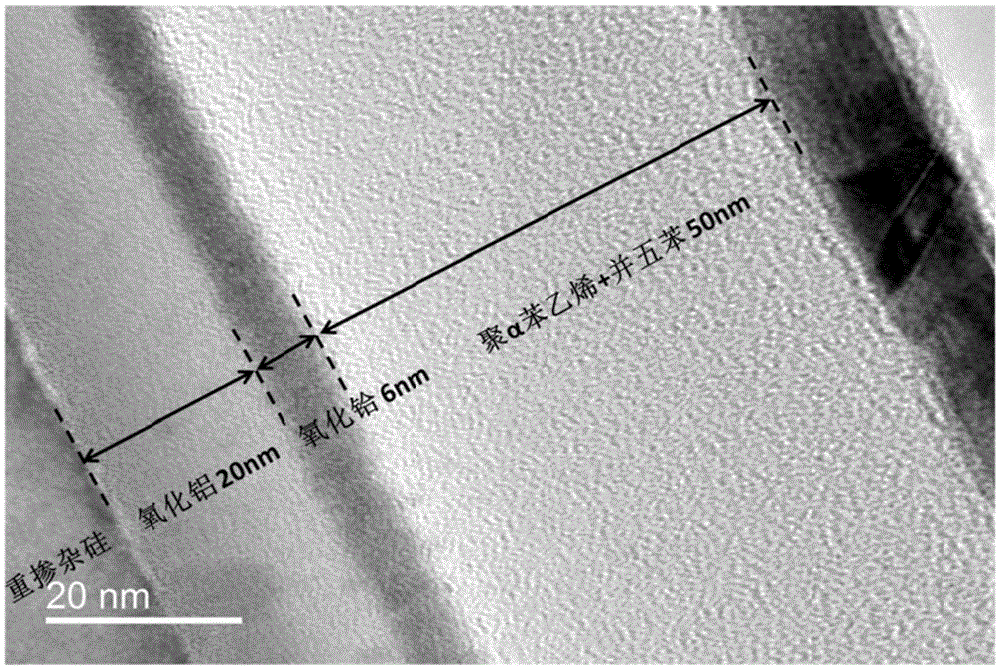

[0046] 2. Preparation of aluminum oxide barrier film: use atomic layer deposition technology to deposit aluminum oxide on a cleaned silicon substrate. The temperature of the silicon substrate is 250 ° C. The precursor reactants are water and trimethylaluminum. The pulse time is 0.0002s, the pulse time of trimethylaluminum is 0.002s, and the pulse cycle number of trimethylaluminum and water is 200 times.

[0047] 3. Preparation of hafnium oxide charge trapping layer film: use electron beam evaporation technology to deposit 6nm hafnium oxide on aluminum oxide, the substrate temperature is 250°C, the deposition rate i...

Embodiment 2

[0054] In this embodiment, the method for preparing an organic nonvolatile memory device based on a high-K material includes the following steps:

[0055] 1. Substrate cleaning: Select a heavily doped P(100) silicon wafer, first clean it by wet chemical method, and then use diluted hydrofluoric acid (0.1% volume concentration) to remove surface oxides.

[0056] 2. Preparation of aluminum oxide barrier film: use atomic layer deposition technology to deposit aluminum oxide on a cleaned silicon substrate. The temperature of the silicon substrate is 200 ° C. The precursor reactants are water and trimethylaluminum. The pulse time is 0.0002s, the pulse time of trimethylaluminum is 0.002s, and the pulse cycle number of trimethylaluminum and water is 100 times.

[0057] 3. Preparation of hafnium oxide charge trapping layer film: use electron beam evaporation technology to deposit 6nm hafnium oxide on aluminum oxide, the substrate temperature is 200°C, the deposition rate is 0.02nm / s, ...

Embodiment 3

[0064] In this embodiment, the method for preparing an organic nonvolatile memory device based on a high-K material includes the following steps:

[0065] 1. Substrate cleaning: Select a heavily doped P(100) silicon wafer, first clean it by wet chemical method, and then use diluted hydrofluoric acid (0.1% volume concentration) to remove surface oxides.

[0066] 2. Preparation of aluminum oxide barrier film: use atomic layer deposition technology to deposit aluminum oxide on a cleaned silicon substrate. The temperature of the silicon substrate is 250 ° C. The precursor reactants are water and trimethylaluminum. The pulse time is 0.0002s, the pulse time of trimethylaluminum is 0.002s, and the pulse cycle number of trimethylaluminum and water is 400 times.

[0067] 3. Preparation of hafnium oxide charge trapping layer film: use electron beam evaporation technology to deposit 10nm hafnium oxide on aluminum oxide, the substrate temperature is 250°C, the deposition rate is 0.02nm / s,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com