Processing system and method for purifying organic wastewater

A technology of organic wastewater and treatment methods, applied in the direction of oxidized water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of difficult regeneration, easy saturation of physical adsorbents, interference of AOP, etc., and achieve simple structure , the effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

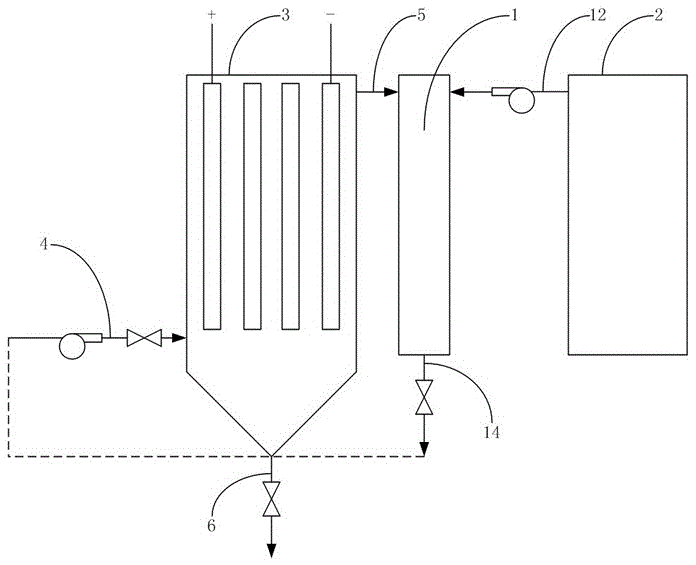

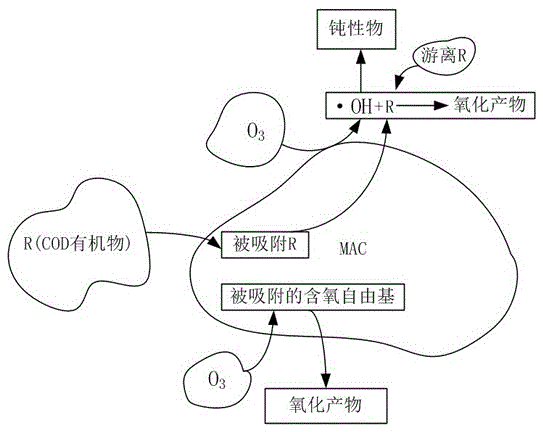

[0083] Embodiment 1. Because leather wastewater contains animal fat and treatment chemicals, the concentration of organic and inorganic pollutants in the water is high, and the water is black and smelly. The waste water cannot be in direct contact with the ozone electrode, and the ozone gas must be pumped to the MAC filter tower by a vacuum pump, and the waste water and ferrous ion Fe flowing in from the EC electrolyzer 2+ Convergence, the organic / inorganic pollutants are recycled; that is, the leather wastewater is circulated between the MAC filter tower and the EC electrolytic cell for treatment until the scheduled treatment time (or reaches the standard). EC electrolyzer, MAC filter tower and EO 3 The composition and operating parameters of the electrolyzer are shown in Table 3:

[0084] .

[0085] The untreated leather waste water is pumped into the EC electrolytic cell by the water transfer pump. When the tank is full, the input of waste water is stopped, and the wast...

Embodiment 2

[0088] Embodiment two, processing cut off oil waste water, the main component of organic matter in water is: [alcohols (n-butanol, diethylene glycol), ethylene oxide, propylene oxide, polyethers (polyoxyethylene ether, polyoxyethylene propylene ether, triethanolamine)], the framework of the pretreatment process is based on distillation. Among them, the raw water COD is about 174,000mg / L. The water sample parameters after distillation are shown in Table 5:

[0089] .

[0090] Table 5 shows that the water sample after distillation is still high COD wastewater that can pollute the environment.

[0091] Put 9L of distilled cutting oil wastewater into the EC electrolyzer, and then carry out circular purification treatment on the wastewater. At regular intervals, water samples were taken from the bottom of the MAC filter tower to measure the COD value, and the results are shown in Table 6:

[0092] .

[0093] Cutting oil wastewater treated by the treatment system of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com