Treatment method of heavy metal waste water

A treatment method and technology for heavy metals, which are applied in multi-stage water treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. Continuous extraction of sludge and other problems, to achieve the effect of saving the amount of chemicals, less floor space, and close arrangement of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

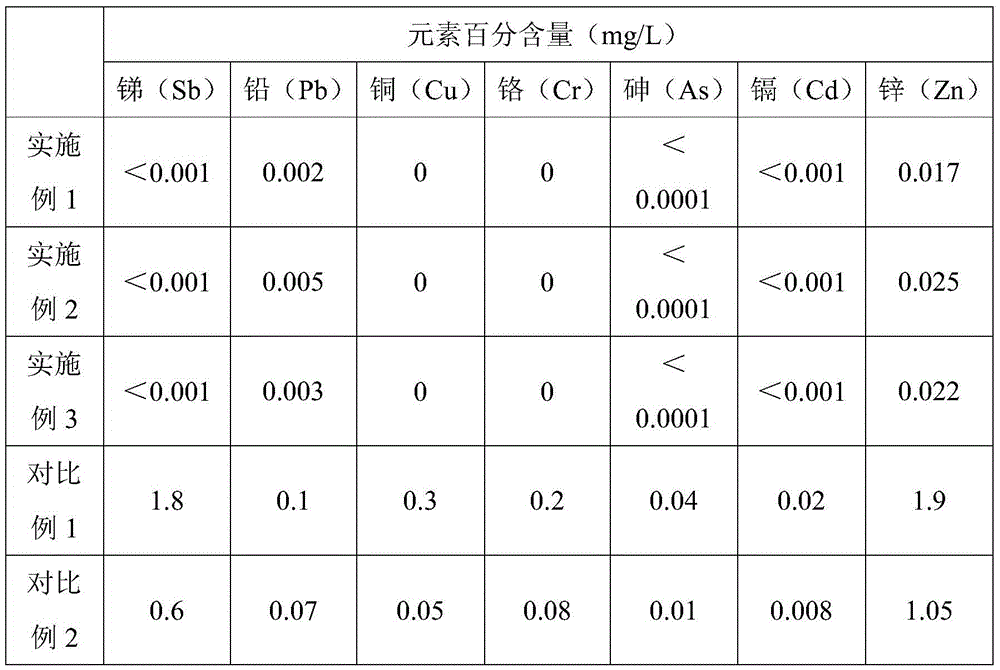

Embodiment 1

[0045] (1) Add a potassium hydroxide solution with a concentration of 10wt% to the heavy metal wastewater to be treated for agitation and neutralization reaction until the pH of the heavy metal wastewater is 7;

[0046] (2) According to the volume ratio of heavy metal wastewater to coagulant of 500:1, add a 0.8% mass concentration of polyferric sulfate solution to the heavy metal wastewater treated in step (1), and stir for 8 minutes to make the heavy metals in the wastewater The ions form hydroxides and precipitate out to become colloidal suspensions in water;

[0047] (3) According to the solid-to-liquid ratio of magnetic agent and heavy metal wastewater in mg / L as 15:1, magnetic agent is added to make the colloidal suspension in the wastewater water have micro-magnetism;

[0048] Among them, the magnetic agent is prepared through the following steps:

[0049] a. Grind iron ore to nano-sized microspheres of 1~500nm;

[0050] b. Disperse the nano-microspheres of step a at 8g / mL in a m...

Embodiment 2

[0060] (1) Add a sodium hydroxide solution with a concentration of 30% by weight to the heavy metal wastewater to be treated for agitation and neutralization reaction until the pH of the heavy metal wastewater is 7;

[0061] (2) According to the volume ratio of heavy metal wastewater to coagulant of 500:2, add a polyferric sulfate solution with a mass concentration of 0.7% to the heavy metal wastewater treated in step (1), and stir for 5 minutes to make the heavy metals in the wastewater The ions form hydroxides and precipitate out to become colloidal suspensions in water;

[0062] (3) According to the solid-to-liquid ratio of magnetic agent and heavy metal wastewater in mg / L, add magnetic agent to make the colloidal suspension in the wastewater have micro-magnetic properties;

[0063] Among them, the magnetic agent is prepared through the following steps:

[0064] a. Grind iron ore to nano-sized microspheres of 1~500nm;

[0065] b. Disperse the nano-microspheres of step a at 1g / mL in ...

Embodiment 3

[0075] (1) Add a sodium hydroxide solution with a concentration of 40% by weight to the heavy metal wastewater to be treated for stirring and neutralization until the pH of the heavy metal wastewater is 7;

[0076] (2) According to the volume ratio of heavy metal wastewater to coagulation agent of 500:1.5, add a 0.6% mass concentration of polyferric sulfate solution to the heavy metal wastewater treated in step (1), and stir for 10 minutes to make the heavy metals in the wastewater The ions form hydroxides and precipitate out to become colloidal suspensions in water;

[0077] (3) According to the solid-to-liquid ratio of magnetic agent and heavy metal wastewater in mg / L as 5:1, magnetic agent is added to make the colloidal suspension in the wastewater water have micro-magnetism;

[0078] Among them, the magnetic agent is prepared through the following steps:

[0079] a. Grind iron ore to nano-sized microspheres of 1~500nm;

[0080] b. Disperse the nano microspheres of step a at 10g / mL ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com