Expansion agent for oil well cement and preparation method thereof

A technology of oil well cement and expansion agent, which is applied in the field of oilfield chemistry, can solve problems such as low fluidity, failure to expand, and instability of ettringite crystals, and achieves wide operating temperature range, simple manufacturing process, and good expansion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, the expansion agent formula is CaO 15%, CaCl 2 15%, MgO 34%, MgSO 4 34%, hydraulically active slag 2%.

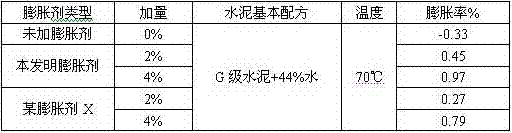

[0036] In the present invention, the expansion agent prepared, the existing expansion agent and the original cement slurry are subjected to the expansion performance comparison experiment, and the experimental data are shown in the following table:

[0037]

[0038] Wherein: a certain expansion agent X, according to the CN1374266A patent document, the raw materials are selected according to the following ratio:

[0039] Bauxite (Al 2 o 3 ): 55%

[0040] Limestone (CaO): 30%

[0041] Gypsum (SO 3 ): 12%

[0042] Bituminous coal: 3%

[0043] According to the method described, get 40% and 60% anhydrite and grind together into expansion agent.

[0044] From the above data, it can be seen that under the condition of 70°C, the expansion performance of the cement system of the expansion agent increases with the increase of the amount of exp...

Embodiment 2

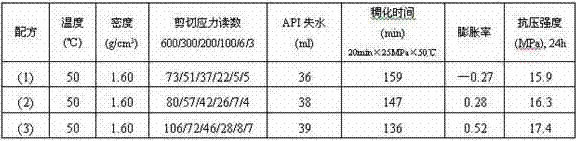

[0046] Investigate the comprehensive performance of the low-density cement slurry after adding the expansion agent prepared by the embodiment of the present invention 1, obtain the results shown in the following table:

[0047]

[0048] Formula: (1) Grade G cement + 15% floating beads + 1.5% G304 + 0.5% USZ + 59% water

[0049] (2) Grade G cement + 15% floating beads + 1.5% G304 + 0.5% USZ + 2.0% expansion agent of the present invention + 59% water

[0050] (3) Grade G cement + 15% floating beads + 1.5% G304 + 0.5% USZ + 2.5% expansion agent of the present invention + 59% water

[0051] Note: Floating beads are lightening agents, which are by-products of combustion in power plant boilers, G304 is fluid loss reducer, and USZ is dispersant, both of which are cement slurry additives.

[0052] From the above experimental results, under the condition of 50°C, the cement strength, API dehydration, thickening time, rheological properties and other characteristics of the cement st...

Embodiment 3

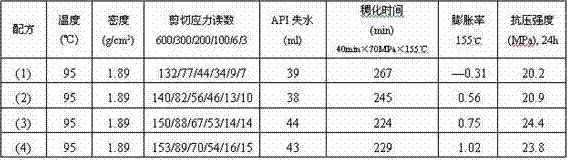

[0054] Investigate the comprehensive performance of the conventional density cement slurry after adding the expansion agent prepared by the embodiment of the present invention 1, obtain the results shown in the following table:

[0055]

[0056] Formula: (1) Grade G cement + 35% SiO 2+1.4%USZ+5%G310+1.4%GH-9+44%Water

[0057] (2) Grade G cement + 35% SiO 2 +1.4%USZ +5%G310+1.4%GH-9+2.0% expansion agent of the present invention+44% water

[0058] (3) Grade G cement + 35% SiO 2 +1.4%USZ +5%G310+1.4%GH-9+2.5% expansion agent of the present invention+44% water

[0059] (4) Grade G cement + 35% SiO 2 +1.4%USZ +5%G310+1.4%GH-9+3.0% expansion agent of the present invention+44% water

[0060] Note: SiO 2 As a heat stabilizer, it can prevent the strength of cement from fading when the temperature exceeds 110°C. USZ is a dispersant, G310 is an anti-high temperature fluid loss reducer, and GH-9 is a retarder, all of which are existing conventional cement slurry additives.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com