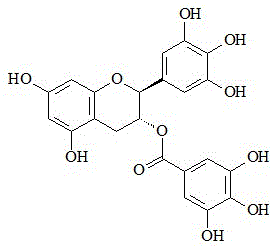

Method for preparing high-purity gallnut catechin gallate (GCG)

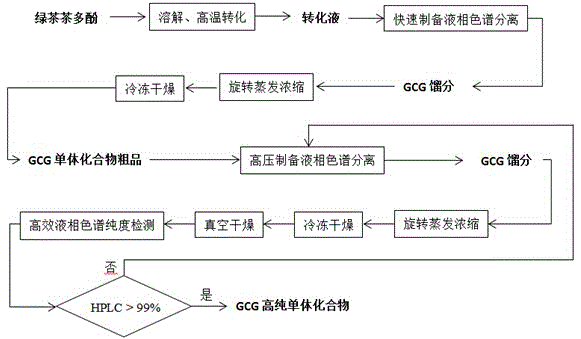

A technology of gallocatechin and gallate, applied in the direction of organic chemistry, etc., can solve the problems of high cost of raw materials, low purity of monomer compounds, etc., and achieve the effects of short separation time, large sample load and simple technical route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

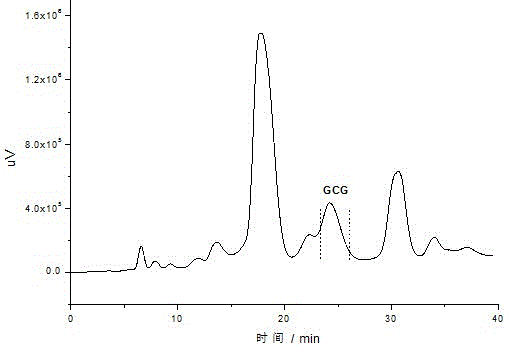

[0055] Weigh 30g of green tea polyphenols (total catechin content>98%, caffeine content image 3 As shown, the gallocatechin gallate GCG fraction was collected for 23.5-25.8 minutes, and the purity of the fraction was detected by high performance liquid chromatography, which was 90.12%. Multiple samples were injected, the combined fractions of gallocatechin gallate GCG were collected, methanol was removed by rotary evaporation at 60°C and recovered, and the concentrated solution was freeze-dried to obtain the crude product of gallocatechin gallate GCG monomer compound. Weigh an appropriate amount of crude gallocatechin gallate GCG monomer compound, dilute it with 25% (volume ratio) methanol aqueous solution, prepare a solution with a concentration of 40 mg / mL, and perform high-pressure preparative liquid chromatography separation. The separation conditions of high-pressure preparative liquid chromatography are: chromatographic column: C18, 10μm, 21.5*250mm; mobile phase A: metha...

Embodiment 2

[0057] Weigh 30g of green tea polyphenols (total catechin content>98%, caffeine content<0.05%) sample, add 1000mL ultrapure water, stir and ultrasonically dissolve, place in a closed container at 100°C oven for high temperature conversion for 300min. Take an appropriate amount of high-temperature conversion solution, filter it with a 0.22 μm microporous membrane, and perform rapid preparative liquid chromatography separation. The rapid preparative liquid chromatographic column is a C18 packing with a mass of 120 g and a particle size of 20-40 μm. The separation conditions are: mobile phase A: methanol, mobile phase B: aqueous solution containing 0.1% (volume ratio) acetic acid; flow rate: 50mL / min; gradient elution: 15%A(0min)–20%A(5min)–25 %A(10min)–30%A(25min)–35%A(30min)–50%A(40min); sample volume: 3mL; detection wavelength: 278nm. The gallocatechin gallate GCG fraction was collected for 23.5-25.8 minutes, and the purity of the fraction was detected by high performance liq...

Embodiment 3

[0059] Weigh 30g of green tea polyphenols (total catechin content>98%, caffeine content<0.05%) sample, add 1000mL ultrapure water, stir and ultrasonically dissolve, place in a closed container at 150°C for high-temperature transformation in an oven for 10min. Take an appropriate amount of high-temperature conversion solution, filter it with a 0.22 μm microporous membrane, and perform rapid preparative liquid chromatography separation. The rapid preparative liquid chromatographic column is a C18 packing with a mass of 120 g and a particle size of 20-40 μm. The separation conditions are: mobile phase A: methanol, mobile phase B: aqueous solution containing 0.1% (volume ratio) acetic acid; flow rate: 50mL / min; gradient elution: 15%A(0min)–20%A(5min)–25 %A(10min)–30%A(25min)–35%A(30min)–50%A(40min); sample volume: 3mL; detection wavelength: 278nm. The gallocatechin gallate GCG fraction was collected for 23.5-25.8 minutes, and the purity of the fraction was detected by high perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com