A nial-based self-lubricating material with ag and mo-b-o-si quaternary plate crystals as a composite lubricating phase and a reinforcing phase and a preparation method thereof

A technology of plate crystals and lubricating materials, which is applied in the field of NiAl-based self-lubricating materials and their preparation, can solve the problems of material mechanical properties degradation, limited tribological properties, and ineffective improvement of lubricating properties, and achieve stable sintering reactions and improved The effect of synthesis efficiency and novel preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

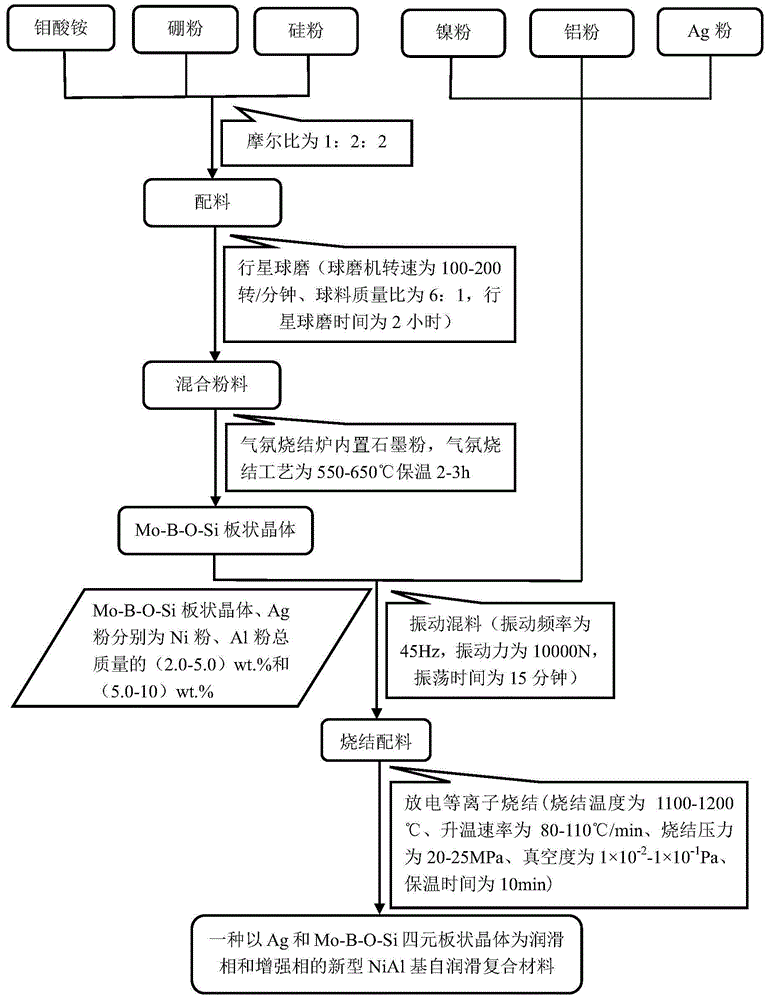

[0034] Such as figure 1 Shown, a kind of preparation method using Ag powder and Mo-B-O-Si quaternary plate crystal as lubricating phase and the NiAl base self-lubricating material of strengthening phase, it comprises the steps:

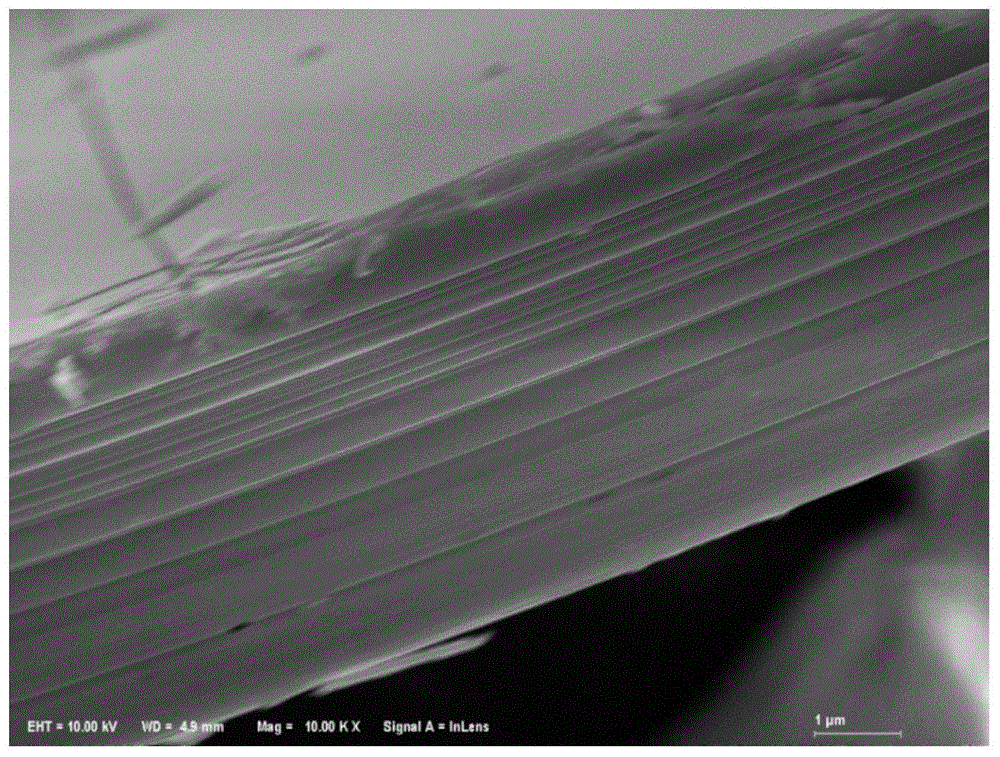

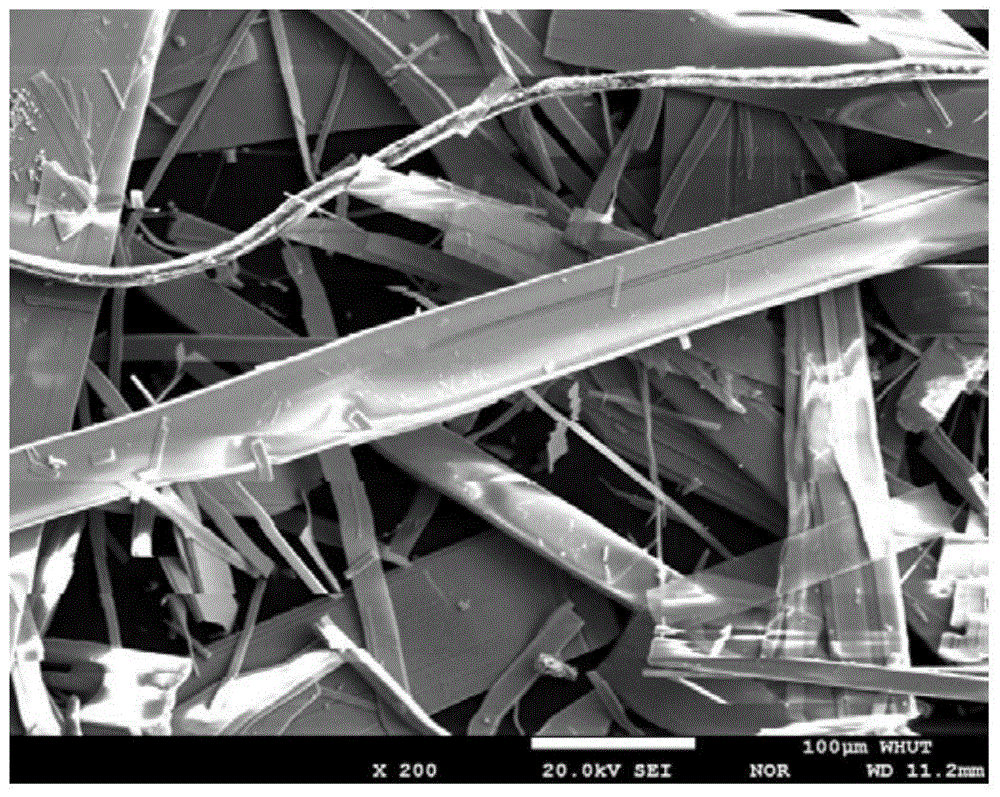

[0035]1) According to the molar ratio of ammonium molybdate: boron powder: silicon powder = 1:2:2, select 0.32 grams of ammonium molybdate powder, 0.04 grams of boron powder and 0.04 grams of silicon powder, and mix ammonium molybdate powder, boron powder and silicon powder The powders are mixed by planetary ball mills to obtain the initial mixture of Mo-B-O-Si quaternary plate crystals; the ingredients after ball milling are sintered in an atmosphere furnace, and graphite powder is placed in the atmosphere sintering furnace. The sintering process is 550 ° C for 3 hours, and the protective gas is argon. In the sintering process, oxygen is introduced, and the amount of oxygen introduced is 50-150ml / min, so as to obtain the Mo-B-O-Si quaternary plate-sh...

Embodiment 2

[0042] 1) According to the molar ratio of ammonium molybdate: boron powder and silicon powder = 1:2:2, select 0.56 grams of ammonium molybdate powder, 0.07 grams of boron powder and 0.07 grams of silicon powder, and mix ammonium molybdate powder, boron powder and silicon powder The powders are mixed by planetary ball mill to obtain the initial mixture of Mo-B-O-Si quaternary plate crystals; the ingredients after ball milling are sintered in an atmosphere furnace, and graphite powder is placed in the atmosphere sintering furnace. The sintering process is 600 ° C for 2.5 hours, and the protective gas is argon gas, and oxygen is fed during the sintering process, and the oxygen feeding rate is 50-150ml / min to obtain the Mo-B-O-Si quaternary plate-shaped crystal.

[0043] 2) Select 13.0 grams of Ni powder, 7.0 grams of Al powder, 1.5 grams of Ag powder and 0.7 grams of the plate-shaped crystal prepared above according to the molar ratio of Ni:Al = 1:1; Ni powder, Al powder, Ag powde...

Embodiment 3

[0048] 1) According to the molar ratio of ammonium molybdate: boron powder and silicon powder = 1:2, select 0.8 g ammonium molybdate powder, 0.1 g boron powder and 0.1 g silicon powder, and mix the ammonium molybdate powder, boron powder and silicon powder planetary Ball milling and mixing to obtain the initial mixture of Mo-B-O-Si quaternary plate crystals; after ball milling, the ingredients are sintered in an atmosphere furnace, graphite powder is placed in the atmosphere sintering furnace, the sintering process is 650 ° C for 2 hours, the protective gas is argon, and sintering Oxygen is introduced during the process, and the amount of oxygen introduced is 50-150ml / min to obtain the Mo-B-O-Si quaternary plate-shaped crystal.

[0049] 2) Select 13.0 grams of Ni powder, 7.0 grams of Al powder, 2.0 grams of Ag powder and 1.0 grams of the plate crystal prepared above according to the molar ratio of Ni:Al = 1:1; Ni powder, Al powder, Ag powder and Mo- B-O-Si quaternary plate cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com