Method for preparing feed additive rich in astaxanthin through co-culture

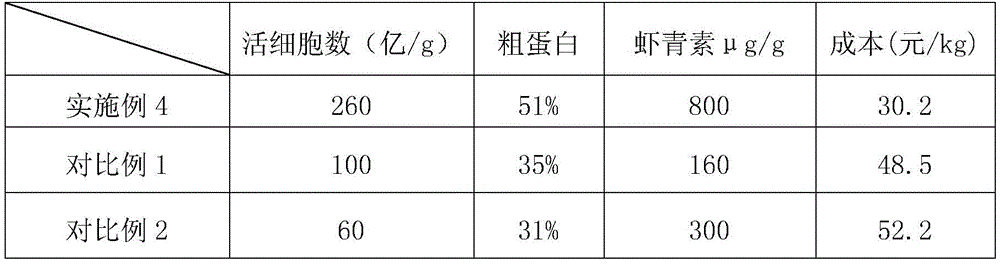

A technology of feed additive and symbiotic culture, applied in the field of symbiotic culture to prepare astaxanthin-rich feed additive, and symbiotic culture to prepare astaxanthin-rich marine red yeast fermented feed additive, which can solve the problem of affecting the function of marine red yeast fermented feed Sex, low astaxanthin content, cost increase and other issues, to achieve the effect of enhancing immunity, cheap price, and improving functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]A method for preparing a feed additive rich in astaxanthin through symbiotic culture, the steps are as follows:

[0046] (1) will contain 2.5×10 8 The seed liquid of Phaffia rhodozyme per ml was inoculated in the liquid fermentation medium according to the volume percentage of 5%. Under the conditions of temperature 25°C, ventilation rate 1.0vvm, and pH 4.5, stir and ferment, and add carbon source during fermentation solution and nitrogen source solution, so that the carbon source concentration in the fermenter is 10g / L, the nitrogen source concentration is 0.8g / L, ferment for 30h, and obtain a fermented liquid;

[0047] The components per liter of the liquid fermentation medium are as follows:

[0048] Sucrose 20g, glucose 10g, corn flour 5g, yeast extract 8g, soybean meal 10g, dipotassium hydrogen phosphate 1.5g, ammonium chloride 5g, anhydrous magnesium sulfate 5g, water to 1L, pH5.2;

[0049] (2) directly inoculate the primary fermented liquid that step (1) makes c...

Embodiment 2

[0074] A method for preparing a feed additive rich in astaxanthin through symbiotic culture, the steps are as follows:

[0075] (1) will contain 2.0×10 8 The seed liquid of Phaffia rhodozyme per ml was inoculated in the liquid fermentation medium according to the volume percentage of 6%, under the conditions of temperature 26°C, ventilation rate 1.2vvm, pH 4.8, stirred and fermented, and carbon source was added during the fermentation solution and nitrogen source solution, so that the carbon source concentration in the fermenter is 15g / L, the nitrogen source concentration is 1.0g / L, ferment for 35h, and obtain a fermented liquid;

[0076] The components per liter of the liquid fermentation medium are as follows:

[0077] Sucrose 25g, glucose 15g, corn flour 8g, yeast extract 10g, soybean meal 6g, dipotassium hydrogen phosphate 1g, ammonium chloride 3g, anhydrous magnesium sulfate 3g, water to 1L, pH5.3;

[0078] (2) directly inoculate the primary fermented liquid that step (...

Embodiment 3

[0103] A method for preparing a feed additive rich in astaxanthin through symbiotic culture, the steps are as follows:

[0104] (1) will contain 1.5×10 8 The seed liquid of Phaffia rhodozyme per ml was inoculated in the liquid fermentation medium according to the volume percentage of 10%. Under the conditions of temperature 26°C, ventilation rate 1.2vvm, pH 4.8, stir and ferment, and add carbon source during the fermentation solution and nitrogen source solution, so that the carbon source concentration in the fermenter is 15g / L, the nitrogen source concentration is 1.0g / L, ferment for 35h, and obtain a fermented liquid;

[0105] The components per liter of the liquid fermentation medium are as follows:

[0106] Sucrose 30g, glucose 15g, corn flour 10g, yeast extract 15g, soybean meal 5g, dipotassium hydrogen phosphate 0.5g, ammonium chloride 5g, anhydrous magnesium sulfate 5g, water to 1L, pH5.4;

[0107] (2) Directly inoculate the primary fermentation broth prepared in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com