A method for preparing non-toxic antibacterial coating on the surface of medical implant material

A technology for implanting materials and antibacterial coatings, applied in coatings, pharmaceutical formulations, medical science, etc., can solve problems such as increased cytotoxicity, achieve the effects of increasing cell proliferation, enhancing biomedical functions, and reducing cytotoxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Nano-silver / Cyclone dipeptide composite films were prepared by pulse electrodeposition. The 10mm×10mm×2mm pure titanium plate was polished step by step with sandpaper to No. 1500, then ultrasonically cleaned with deionized water, acetone, ethanol and deionized water for 10 min respectively, and then dried. A 0.5% HF solution was prepared as the electrolyte, the polished titanium plate was used as the anode, and the large-area platinum electrode was used as the cathode to form a two-electrode electrolytic cell. The mechanical stirring of 200 r / min was applied to the system, the water bath was kept at a constant temperature, and the temperature of the system was controlled to be room temperature, about 25 °C. A regulated power supply was used to provide power to the electrolytic cell and electrochemical anodization was carried out under the condition of 20V constant voltage for 20min.

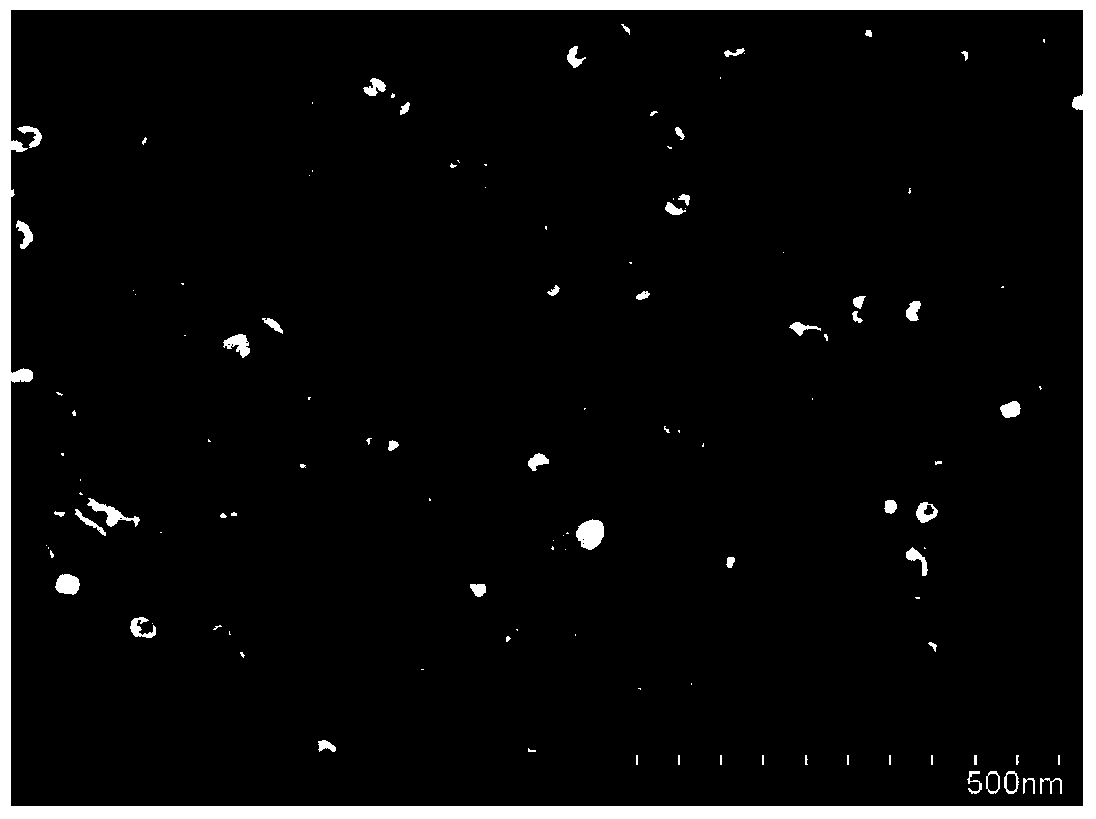

[0038] The electrolyte contains AgNO 3 0.01mol / L, NaNO 3 0.1mol / L, the concentratio...

Embodiment 2

[0040] The silver mirror reaction was used to prepare the nano-silver / proglutamate dipeptide composite film. The pretreatment method and electrochemical anodic oxidation treatment process of 10mm × 10mm × 2mm pure titanium plate are the same as those in Example 1. Now add 10 ml of silver ammonia solution, add 3 ml of 2 mol / L glucose solution, and the concentration of proglutamate dipeptide is 0.05 mol / L. The resulting titanium or titanium alloy is immersed in the solution, rinsed with deionized water after the reaction, and dried in the air. The anodized titanium or titanium alloy is immersed in the solution, rinsed with deionized water after the reaction, and dried in the air. The temperature is controlled at 25°C, and the reaction time is 20min. , to obtain a uniform distribution in TiO 2 The Ag nanoparticles in the mouth of the nanotube and in the tube, the particle size of the Ag nanoparticles is 30-60 nm (the present invention generally describes this morphology as morpho...

Embodiment 3

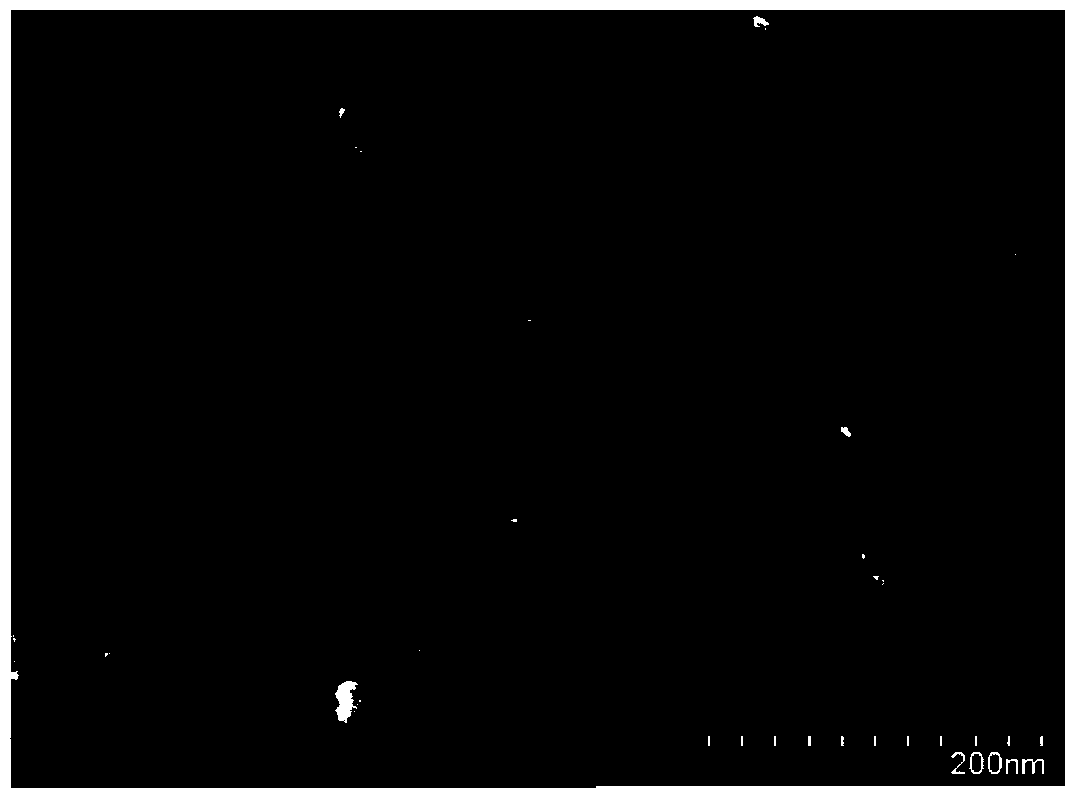

[0042] Nano-silver / Cyclone dipeptide composite film was prepared by ultraviolet light reduction method. The pretreatment method and electrochemical anodic oxidation treatment process of 10mm×10mm×2mm pure titanium plate are the same as in Example 1, and the preparation solution: AgNO-containing 3 1mol / L, the concentration of C-glutamate dipeptide is 0.05mol / L, the anodized titanium or titanium alloy is immersed in the solution, rinsed with deionized water, dried, soaked for 10min, taken out and placed in a mercury lamp (200W, 100mW / cm 2 ) under irradiation for 10 min, a uniform distribution of TiO particles can be obtained. 2 The Ag nanoparticles in the mouth of the nanotube and in the tube, the particle size of the Ag nanoparticles is 1-10 nm (the present invention generally describes this morphology as morphology three, such as image 3 shown). Adjusting the soaking time and soaking times can control the particle size of Ag nanoparticles to change within 1-30 nm, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com