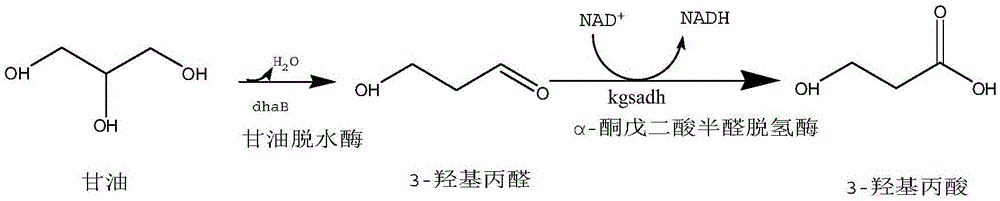

Recombinant Escherichia coli for producing 3-hydroxypropionic acid and application

A technology for recombining Escherichia coli and hydroxypropionic acid, applied in microorganism-based methods, bacteria, microorganisms, etc., can solve problems such as increasing production cost, high price, and increasing difficulty in operation, and achieves the effects of improving efficiency and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Replacement of promoters in plasmids

[0046] Strains and plasmids: E.coliBL21(DE3) was purchased from Transgen, and expression plasmids pACYCDuet-1 and pCDFDuet-1 were purchased from Novozymes.

[0047] The replacement of promoters in plasmids pACYCDuet-1 and pCDFDuet-1 is to replace the sequence of T7 promoter on the plasmid with the sequence of tac promoter through homologous recombination.

[0048] Take the replacement of the T7 promoter of the pACYCDuet-1 plasmid with the tac promoter as an example. Cultivate the Escherichia coli strain containing the plasmid pACYCDuet-1, then use the pACYCDuet-1 plasmid as a template, use mutation primers to mutate the T7 sequence on the plasmid template into tac, and then chemically transform the reaction solution after digesting the template with DpnI endonuclease into BL21(DE3) competent cells. Then spread on the LB solid medium plate containing 50mg / L chloramphenicol, and PCR screen positive clones. Recombinant p...

Embodiment 2

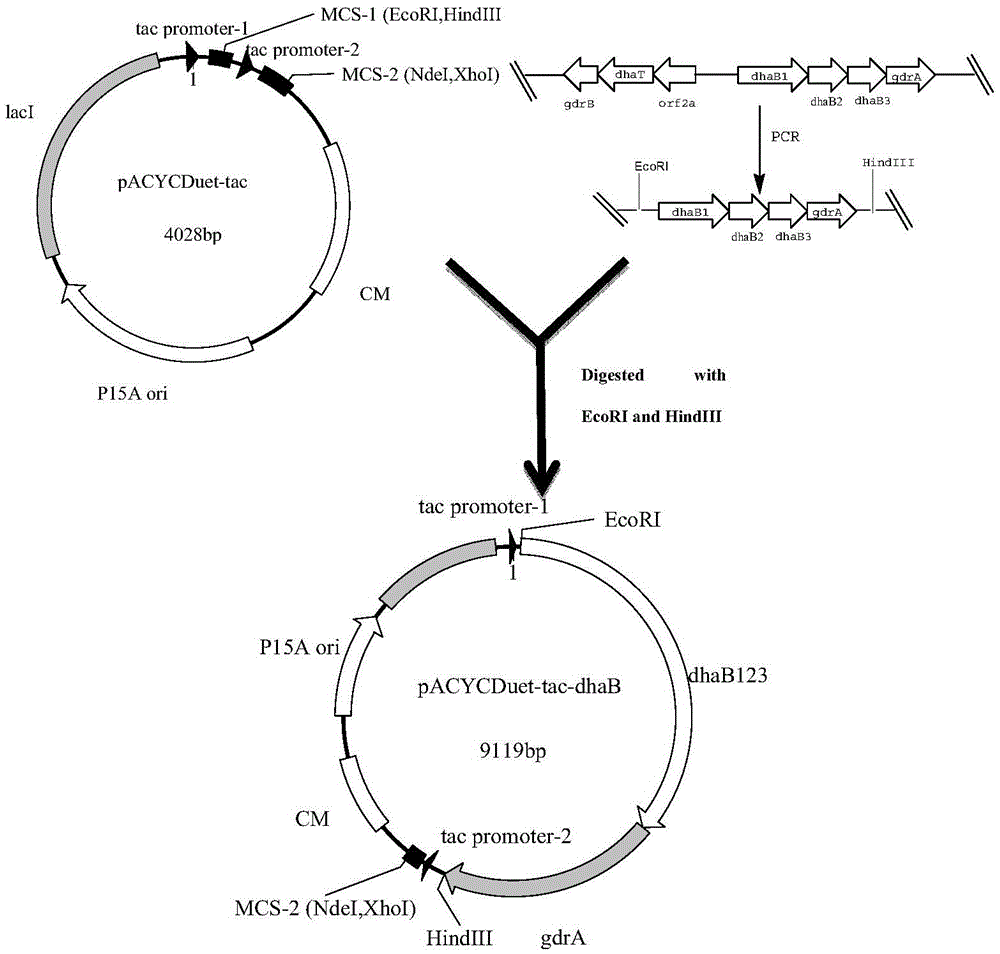

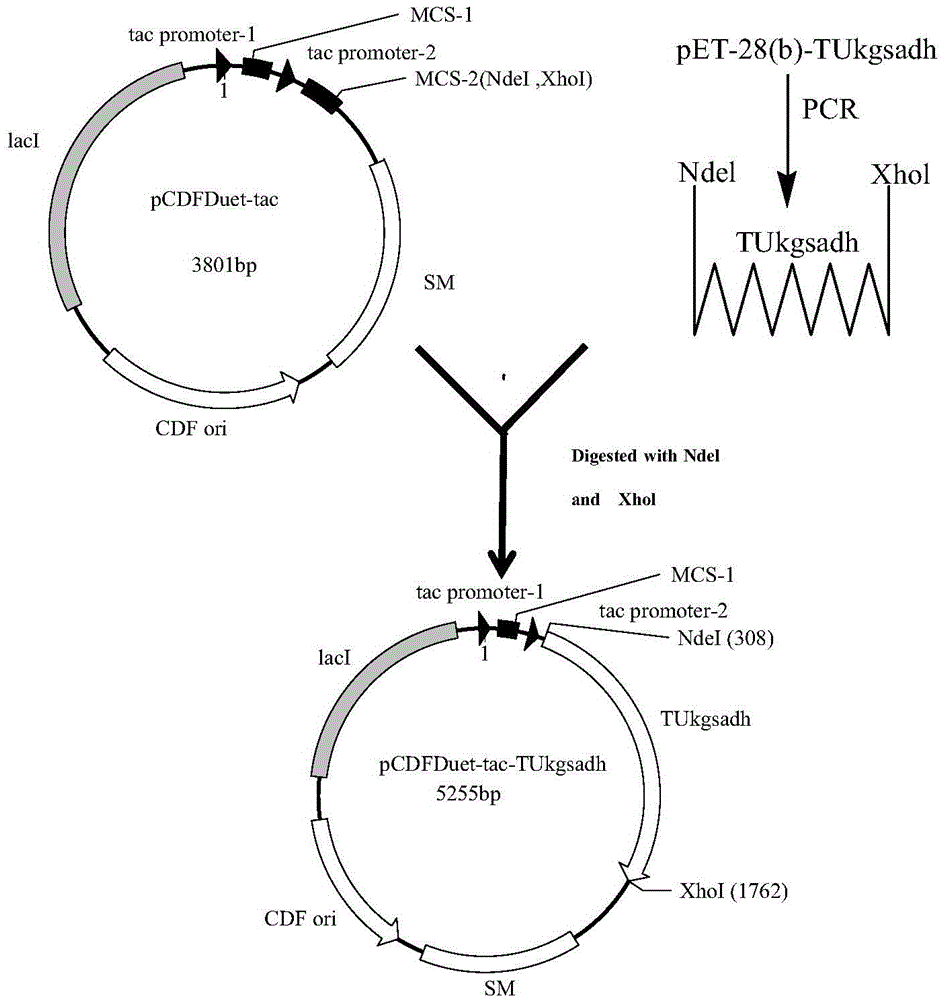

[0056] 1. Cloning and expression of glycerol dehydratase and glycerol dehydratase activator in Klebsiella pneumoniae

[0057] (1) Bacterial strains and plasmids: Klebsiella pneumoniae (K. peneumoniaeDSM2026) was purchased from German DSM Company, E. coliBL21 (DE3) was purchased from Transgen Company, and the expression plasmid pACYCDuet-tac was constructed by the method in Example 1.

[0058] (2) Glycerol dehydratase gene (dhaB123) (dhaB1GeneID: 7947197; dhaB2GeneID: 7947198; dhaB3GeneID: 7947200) and glycerol dehydratase activator gene (gdrA) (gdrAGeneID: 6936977) were cloned using K. peneumoniaeDSM2026 as a template by PCR Amplified obtained. (the primer sequence of amplifying glycerol dehydratase gene and glycerol dehydratase activator gene is: DhaB1-4-F-EcoR1: CCG GAATTC ATGAAAAGATCAAAACGATTTGCAGTACT, DhaB1-4-R-HindIII:GTT AAGCTT GATCTCCCACTGACCAAAGCTGG)

[0059] The amplified product was recovered by the Clean-up kit to recover the target gene fragment.

[0060] (3)...

Embodiment 3

[0087] Embodiment 3: shake flask fermentation test of recombinant strain and recombinant strain implement the expression of SDS-PAGE target protein

[0088] The recombinant Escherichia coli constructed by the method in Example 2 was inoculated into LB medium containing 50 mg / L chloramphenicol and 50 mg / L streptomycin sulfate, and cultured at 37°C for 16 hours to obtain activated recombinant Escherichia coli.

[0089] The activated recombinant Escherichia coli was inoculated into LB liquid medium containing 50 mg / L chloramphenicol and 50 mg / L streptomycin sulfate, and cultured at 37° C. for 10 h to obtain seed liquid.

[0090] The seed solution was inoculated into a 250 mL shake flask containing 50 mL of fermentation medium containing 50 mg / L chloramphenicol and 50 mg / L streptomycin sulfate according to the inoculation amount of 6% volume concentration, and cultured with shaking at 37 ° C and 150 rpm. When OD 600 When it reaches about 0.6, add IPTG to the fermentation broth, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com