Method and kit for high throughput testing of enzymatic activity in lipase in liquid milk product

A lipase enzyme and dairy product technology, which is applied in the field of high-throughput detection of lipase enzyme activity in liquid dairy products, can solve the problems of tedious time-consuming, large errors, etc., achieve less reagent usage, reduce product deterioration, and detect threshold low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1, UHT Skim Milk Lipase Enzyme Activity Detection

[0048] (1) Kit for detecting lipase enzyme activity

[0049] A kit for detecting biotinidase enzyme activity, comprising the following components:

[0050] Reagent 1:

[0051] Glycine-sodium hydroxide buffer solution, the pH value is 9.40, wherein the molar concentration of glycine is 150mM, and the molar concentration of sodium hydroxide is 56mM;

[0052] Reagent 2:

[0053] The acetonitrile solution of p-nitrophenyl palmitate, wherein the molar concentration of p-nitrophenyl palmitate is 50mM;

[0054] Reagent 3:

[0055] Stop solution, dairy clarifier.

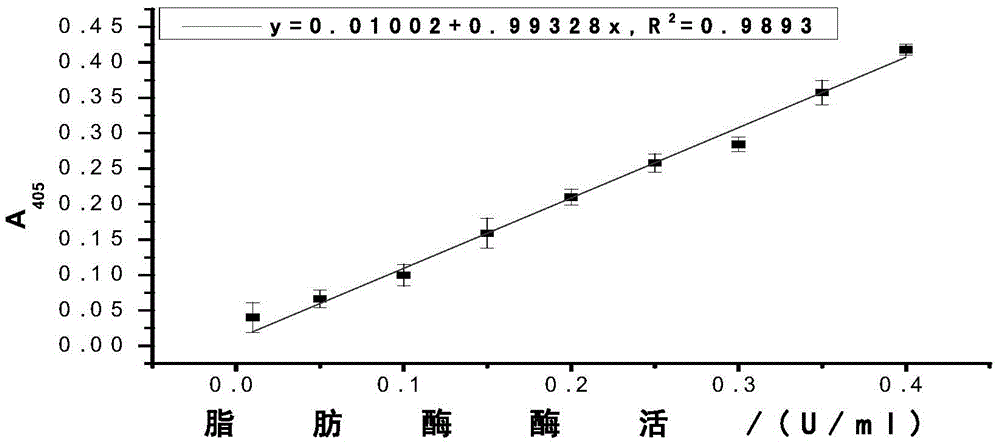

[0056] (2) Drawing of lipase enzyme activity standard curve

[0057] 1) Preparation of UHT skim milk with different lipase activities

[0058] UHT skim milk with lipase activity of 0U, 0.01U, 0.05U, 0.10U, 0.2U, 0.3U and 0.4U were prepared respectively.

[0059] 2) Detection steps of lipase enzyme activity

[0060] a. Add 50 μl of Reagent 1 and 10 μl ...

Embodiment 2

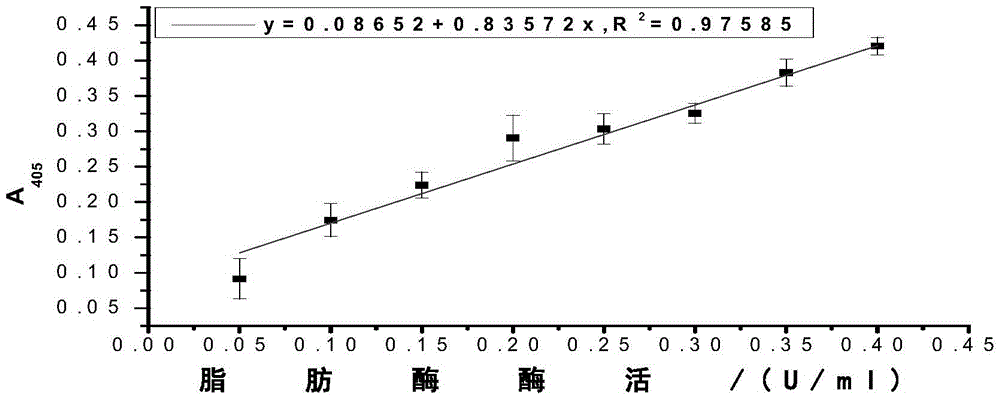

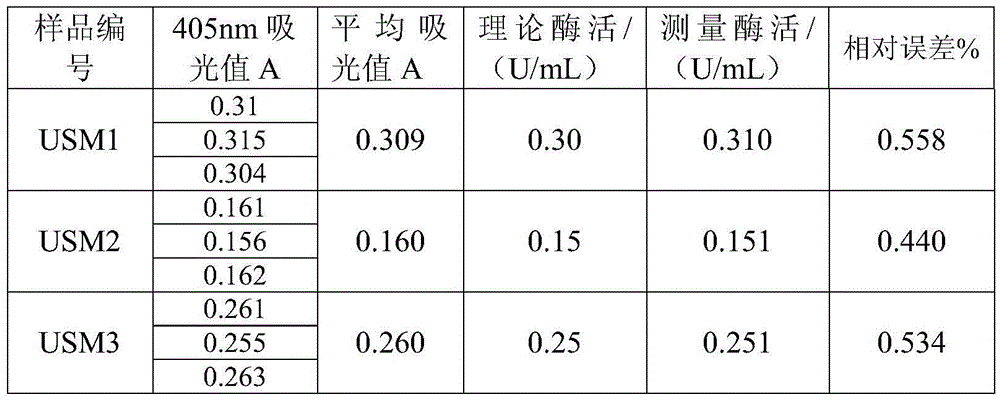

[0074] Example 2, UHT whole milk lipase activity detection

[0075] (1) Kit for detecting lipase enzyme activity

[0076] Composition is the same as in Example 1.

[0077] (2) Standard curve of lipase enzyme activity

[0078] 1) Preparation of UHT whole milk with different lipase activity

[0079] UHT whole milk with lipase activity of 0U, 0.01U, 0.05U, 0.10U, 0.2U, 0.3U and 0.4U were prepared respectively.

[0080] 2) Detection steps of lipase enzyme activity

[0081] a. Add 50 μl of Reagent 1 and 10 μl of UHT whole milk with lipase activity of 0.01U, 0.05U, 0.10U, 0.2U, 0.3U and 0.4U into the wells of a 96-well microplate, shake and mix, and keep at 45°C Incubate for 5 minutes;

[0082] b. Add 10 μl of Reagent 2 to the wells of the microplate, shake and mix, and react at 45°C for 20 minutes;

[0083] c. Add 50 μl of Reagent 3 to the wells of the microplate, shake and mix, and place at 45°C for 5 minutes to terminate the reaction and clarify the system;

[0084] d. At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com