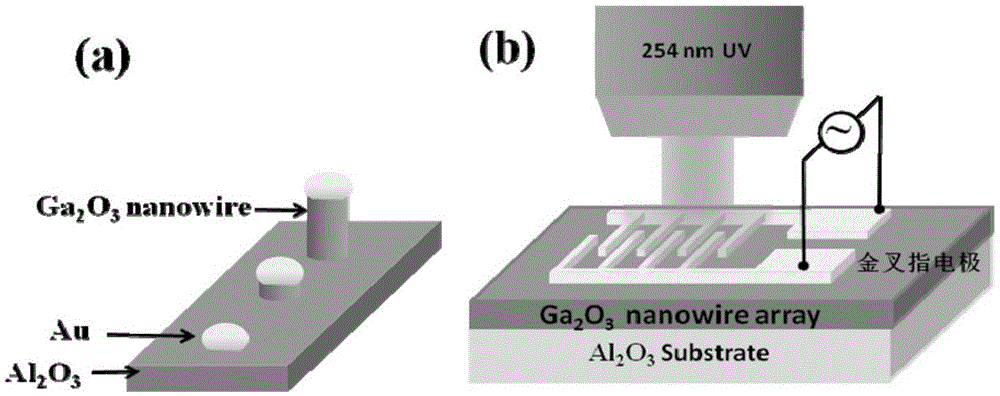

Ultraviolet detector based on gallium oxide nanowire array and preparation method thereof

A nanowire array, gallium oxide technology, applied in semiconductor devices, electrical components, final product manufacturing, etc., can solve the problems of weak signal processing ability, interference, etc., and achieve the effect of sensitive response, stable performance and rapid compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Proceed as follows:

[0032] 1)Al 2 o 3 Substrate pretreatment: Al 2 o 3 The substrate is put into V(HF):V(H 2 o 2 )=1:5 solution soaked to remove the natural oxide layer, then ultrasonic cleaning with acetone, ethanol and deionized water respectively, and vacuum drying;

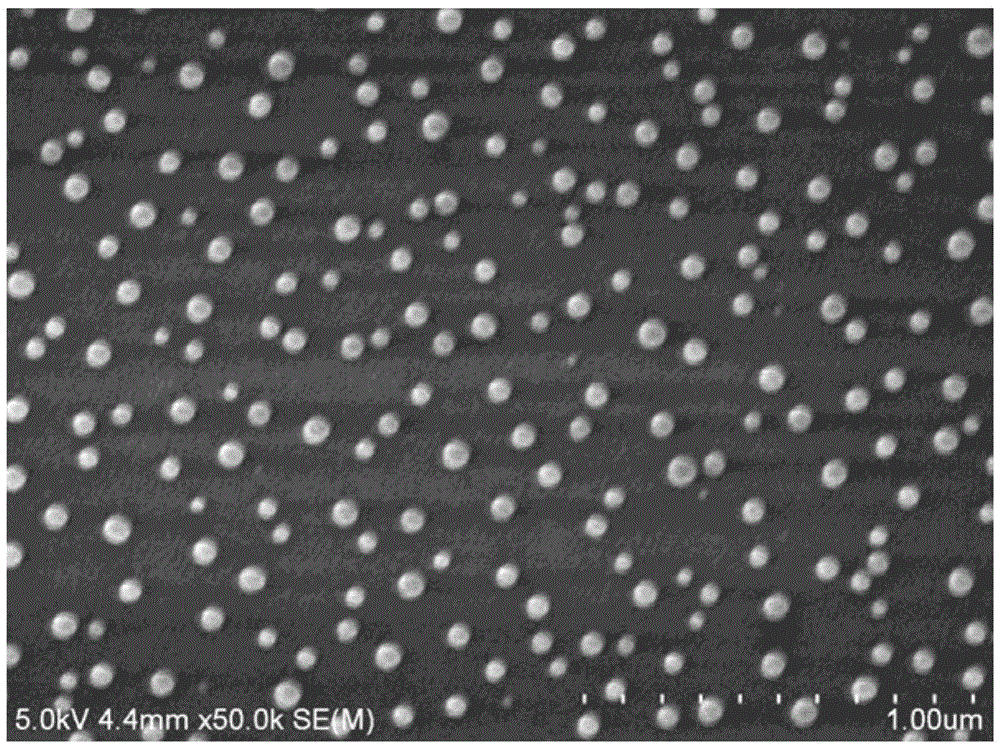

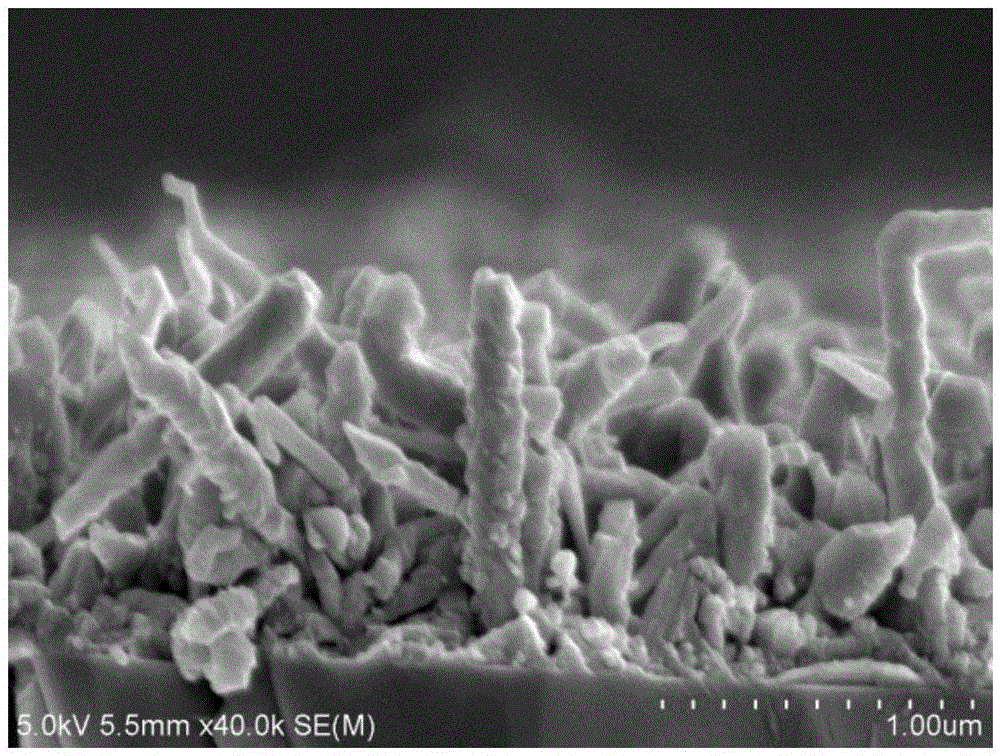

[0033] 2) Place the target and substrate: put the gold target and Ga 2 o 3 The targets are respectively placed on the target stage position of the radio frequency magnetron sputtering system, and the Al after step 1) is processed 2 o 3 The substrate is fixed on the sample holder and put into the vacuum chamber; the preparation process of gold nanoparticles: firstly evacuate the chamber, inject argon gas, adjust the pressure in the vacuum chamber, turn on the radio frequency control power supply of the gold target, and 2 o 3 Deposit a layer of gold film on the substrate, then turn off the radio frequency power supply, pass in oxygen, and heat the Al 2 o 3 substrate, in-situ spheroidizing an...

Embodiment 2

[0039] Steps (1), (2) and (5) are all the same as in Example 1. In step (3), the chamber is first evacuated, argon gas is introduced, the pressure in the vacuum chamber is adjusted, and the radio frequency control power supply of the gold target is turned on. 2 o 3 Deposit a layer of gold film on the substrate, then turn off the radio frequency power supply, pass in oxygen, and heat the Al 2 o 3 substrate, in situ spheroid annealing of the gold film to obtain gold nanoparticles; where the gold target and Al 2 o 3 The distance between the substrates is set to 5 cm. After the argon gas is introduced, the pressure of the vacuum chamber is 0.8 Pa. After the oxygen is introduced, the pressure of the vacuum chamber is adjusted to 10 Pa. 3 Pa, the sputtering power is 20W, the deposition time is 20 seconds, the in-situ spheroidizing annealing temperature is 750°C, and the temperature is kept for 0.5 hours. After step 3) the spheroidizing annealing is completed, open the Ga 2 o ...

Embodiment 3

[0042] Steps (1), (2) and (5) are all the same as in Example 1. In step (3), the chamber is first evacuated, argon gas is introduced, the pressure in the vacuum chamber is adjusted, and the radio frequency control power supply of the gold target is turned on. 2 o 3 Deposit a layer of gold film on the substrate, then turn off the radio frequency power supply, pass in oxygen, and heat the Al 2 o 3 substrate, in situ spheroid annealing of the gold film to obtain gold nanoparticles; where the gold target and Al 2 o 3 The distance between the substrates is set to 5 cm. After the argon gas is introduced, the pressure of the vacuum chamber is 0.8 Pa. After the oxygen is introduced, the pressure of the vacuum chamber is adjusted to 10 Pa. 3 Pa, the sputtering power is 20W, the deposition time is 10 seconds, the in-situ spheroidizing annealing temperature is 750°C, and the temperature is kept for 0.5 hours. After step 3) the spheroidizing annealing is completed, open the Ga 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com