Method and system for adjusting acidity and alkalinity of water in vinyl chloride rectification process

A technology of vinyl chloride and pH, which is applied in chemical instruments and methods, distillation adjustment/control, preparation of halogenated hydrocarbons, etc. It can solve the problems of reducing the whiteness of resin products, affecting product quality, and reducing the thermal stability of finished products. Effects of generation of iron ions, reduction of yellow spot impurities, and improvement of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

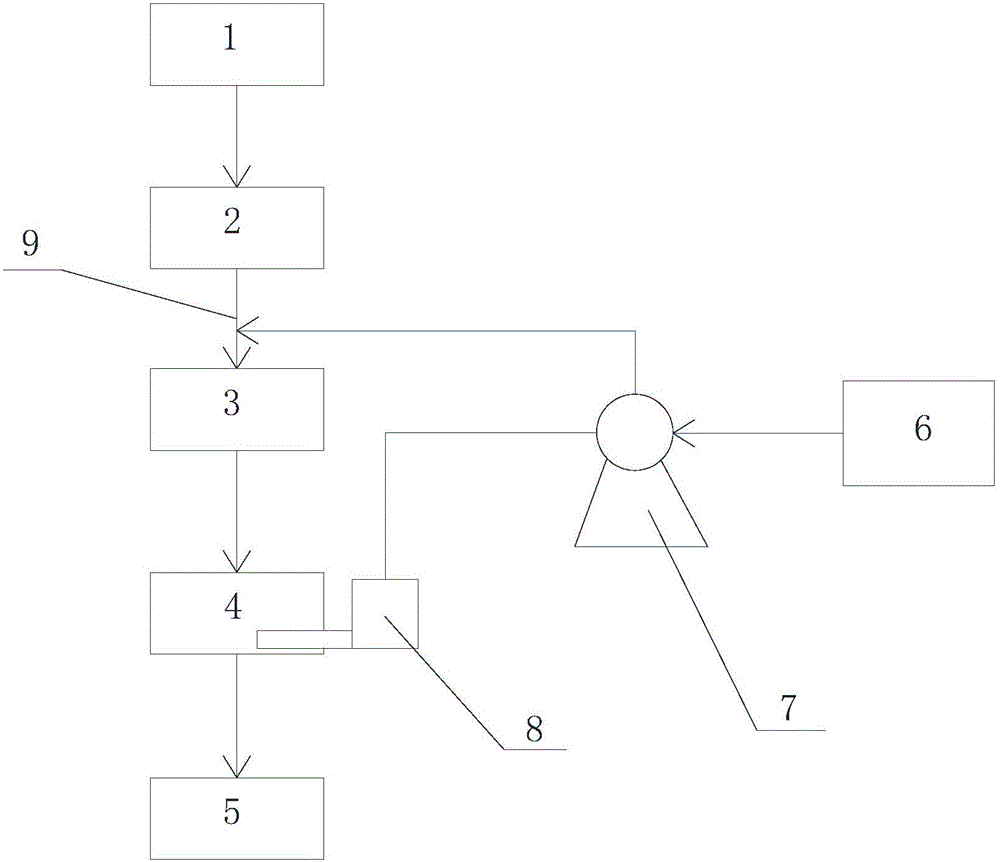

[0019] Embodiment 1: as figure 1 As shown, the pH system for adjusting the liquid vinyl chloride monomer in the vinyl chloride rectification process includes a compressor 1, an after-machine condenser 2, a water separator 3, a crude vinyl chloride monomer storage tank 4, and a refined vinyl chloride monomer. Distillation tower 5, alkali tank 6, plunger pump 7 and pH meter 8, the outlet of compressor 1 is connected with the crude vinyl chloride monomer inlet of after-machine condenser 2, and the thick monomer outlet of vinyl chloride of after-machine condenser 2 is connected with The inlet of the water separator 3 is connected through the liquid vinyl chloride outlet pipe 9, the outlet of the thick monomer of vinyl chloride of the water separator 3 is connected with the inlet of the thick monomer storage tank 4 of vinyl chloride, and the outlet of the thick monomer storage tank of vinyl chloride 4 is connected with the outlet of the thick monomer storage tank of chlorine. The i...

Embodiment 2

[0020] Embodiment 2: Utilize embodiment 1 system to adjust the pH method of liquid vinyl chloride monomer in the rectification process of vinyl chloride, draw the sodium hydroxide solution that mass concentration is 30% from alkali tank 6 with plunger pump 7, then hydrogen The sodium oxide solution is continuously added to the water separator 3 from the liquid vinyl chloride outlet pipe 9, and the sodium hydroxide solution enters the crude vinyl chloride monomer storage tank 4 through the water separator 3 together with the liquid vinyl chloride monomer, and is placed in the crude vinyl chloride monomer storage tank 4. The acidic medium is neutralized in the body storage tank 4. Measure the pH value of the liquid vinyl chloride monomer in the thick monomer storage tank 4 of vinyl chloride by a pH meter 8, so as to control the dripping amount of the plunger pump 7, and make the liquid vinyl chloride single in the thick monomer storage tank 4 of vinyl chloride The pH value of th...

Embodiment 3

[0021] Embodiment 3: Utilize embodiment 1 system to adjust the pH method of liquid vinyl chloride monomer in the vinyl chloride rectification process, draw the potassium hydroxide solution that mass concentration is 32% from alkali tank 6 with plunger pump 7, then hydrogen Potassium oxide solution is continuously added to the water separator 3 from the liquid vinyl chloride outlet pipe 9, and the potassium hydroxide solution enters the crude vinyl chloride monomer storage tank 4 through the water separator 3 together with the liquid vinyl chloride monomer. The acidic medium is neutralized in the body storage tank 4. Measure the pH value of the liquid vinyl chloride monomer in the thick monomer storage tank 4 of vinyl chloride by a pH meter 8, so as to control the dripping amount of the plunger pump 7, and make the liquid vinyl chloride single in the thick monomer storage tank 4 of vinyl chloride The pH value of the body was controlled at 7.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com