Method for resourcefully using vanadium extracting wastewater for producing ammonia-hydrocarbon denitrifying agent

A hydrocarbon denitration agent and resource utilization technology, applied in chemical instruments and methods, water pollutants, neutralized water/sewage treatment, etc., can solve problems such as increased energy consumption, environmental pollution, high operating costs, and secondary pollution , to achieve the effects of saving energy, reducing consumption and environmental protection, improving the economic benefits of enterprises, and promoting energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

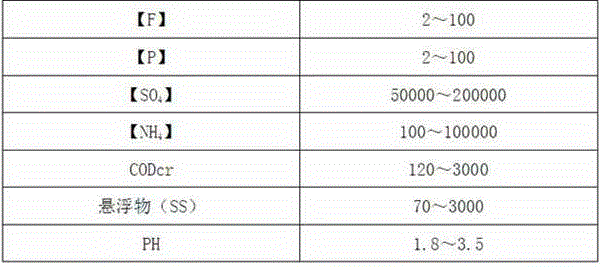

[0048] The vanadium extraction wastewater was selected from a vanadium precipitation wastewater roasted with sodium slag, and the water-liquid property regulator was selected from commercially available monoethanolamine, NO X Triethanolamine is selected as the reducing agent, and hydrazine hydrate is selected as the denitrification accelerator. According to the following steps, ammonia-hydrocarbon denitrification agent (referred to as denitrification agent) is directly prepared from vanadium extraction wastewater as the main raw material:

[0049] (1) Adjust the properties of the vanadium extraction wastewater: put the vanadium extraction wastewater in a stirring tank, add ethanolamine, an aqueous liquid property regulator, to adjust the pH value to 6.1, and obtain solution A;

[0050] (2) Preparation of ammonia-hydrocarbon denitrification agent: use the obtained solution A as the main raw material and NO X The reducing agent triethanolamine and the denitrification accelerato...

Embodiment 2

[0052] Vanadium-extracting wastewater was selected from vanadium-containing wastewater roasted by sodium-containing stone coal, and the water-liquid property regulator was selected from commercially available N-methyl monoethanolamine, NO X Commercially available ammonium carbonate and isopropanol are selected as the reducing agent, and carbohydrazide is selected as the denitrification accelerator. According to the following steps, ammonia-hydrocarbon denitrification agent (referred to as denitrification agent) is directly prepared from vanadium extraction wastewater as the main raw material:

[0053] (1) Adjust the properties of the vanadium extraction wastewater: put the vanadium extraction wastewater in a stirring tank, add N-methyl monoethanolamine to adjust the pH value to 6.3, and obtain solution A;

[0054] (2) Preparation of ammonia-hydrocarbon denitrification agent: use the obtained solution A as the main raw material and NO XThe reducing agent ammonium carbonate, is...

Embodiment 3

[0056] The vanadium extraction wastewater was selected from a factory that used a fluidized bed furnace to roast vanadium-containing stone coal without salt, and the water-liquid property regulator was selected from commercially available ammonium carbonate, NO X Commercially available ammonia water (27% mass concentration) and glucose (waste liquid) were selected as the reducing agent, and hydrazine hydrate was selected as the denitrification accelerator. According to the following steps, the ammonia-hydrocarbon denitrification agent is directly prepared from vanadium extraction wastewater as the main raw material:

[0057] (1) Adjust the properties of the vanadium extraction wastewater: put the vanadium extraction wastewater in a stirring tank, add ammonium carbonate, an aqueous liquid property regulator, to adjust the pH value to 7.8, and obtain solution A;

[0058] (2) Preparation of ammonia-hydrocarbon denitrification agent: the obtained solution A is used as the main raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com