Hyperbranched ammonium salt type cationic surface active agent and preparation and application

A surfactant and cationic technology, which is applied in the field of hyperbranched ammonium salt cationic surfactant and synthesis, can solve the problems of particle re-aggregation or precipitation, weak adsorption of solid particles, poor system stability, etc., and achieve the goal of promoting homogeneity Formation, good dispersion effect, effect under mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

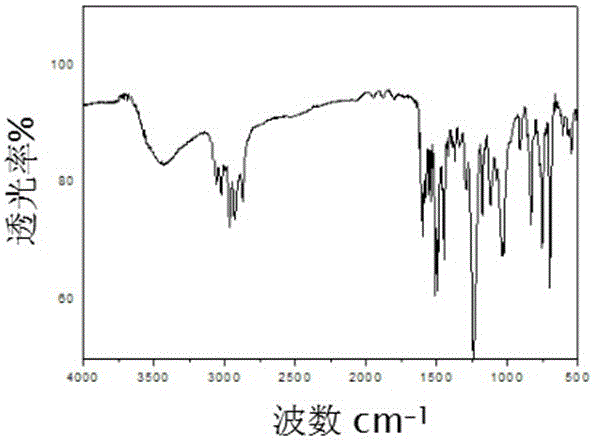

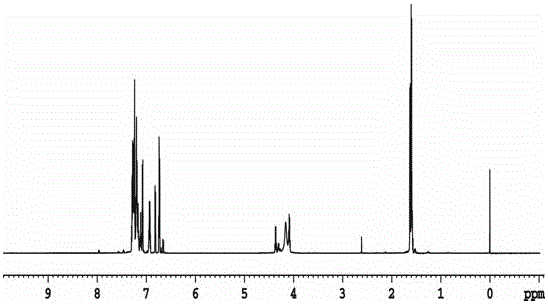

[0045] 1) Synthesis of hyperbranched ammonium salt cationic surfactants.

[0046] Phenol and oxalic acid, which is 1% by mass percentage based on the total amount of monomers, are added to the reaction flask, and nitrogen protection is introduced, and the temperature is raised to 100° C. under stirring, and styrene is slowly added dropwise (the molar ratio of styrene to phenol is 1: 1.5), reacted for 4 hours, stopped the reaction and cooled to room temperature to obtain 4-phenethylphenol with a yield of 94%.

[0047] Add 4-phenethylphenol and triethylamine with a mass percentage of 4% based on the total amount of monomers into the reaction flask, dissolve in absolute ethanol that is 5 times the total weight of the monomers, and heat up to 80°C under stirring , slowly drop epichlorohydrin (the molar ratio of 4-phenethylphenol to epichlorohydrin is 1:1.1), react for 4h, stop the reaction and cool to room temperature, that is, 1-cyclopropylmethoxy-4- Phenylethylbenzene, yield 90...

Embodiment 2

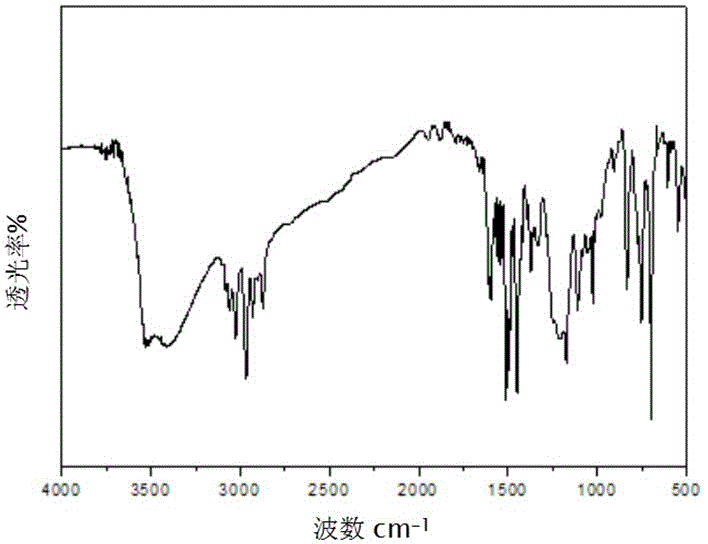

[0064] Phenol and 1% concentrated phosphoric acid based on the total amount of monomers were added to the reaction flask, and nitrogen protection was introduced, and the temperature was raised to 100°C under stirring, and styrene was slowly added dropwise (the molar ratio of styrene to phenol was 1 : 1.5), reacted for 4h, stopped the reaction and cooled to room temperature to obtain 4-phenethylphenol with a yield of 98%.

[0065] Add 4-phenethylphenol and potassium carbonate with a mass percentage of 4% based on monomers into the reaction flask, dissolve in absolute ethanol that is 5 times the total mass of the monomers, heat up to 80°C under stirring, and slowly drop Add epichlorohydrin (the molar ratio of 4-phenethylphenol to epichlorohydrin is 1:1.1), react for 4 hours, stop the reaction and cool to room temperature to obtain 1-cyclopropylmethoxy-4-phenethyl Benzene, yield 92%.

[0066] Dissolve polyethyleneimine in acetone 5 times the total mass of the monomers, add it to...

Embodiment 3

[0070] Phenol and 1% concentrated nitric acid based on the total amount of monomers were added to the reaction flask, and nitrogen protection was introduced, and the temperature was raised to 100°C under stirring, and styrene was slowly added dropwise (the molar ratio of styrene to phenol was 1 : 1.5), reacted for 5h, stopped the reaction and cooled to room temperature to obtain 4 phenethylphenol with a yield of 98%.

[0071] Add 4-phenethylphenol and potassium hydroxide with a mass percentage of 4% based on the total amount of monomers into the reaction flask, dissolve in absolute ethanol that is 5 times the total weight of the monomers, and heat up to 80°C under stirring , slowly drop epichlorohydrin (the molar ratio of 4-phenethylphenol to epichlorohydrin is 1:1.1), react for 4h, stop the reaction and cool to room temperature, that is, 1-cyclopropylmethoxy-4- Phenylethylbenzene, yield 90%.

[0072] Dissolve polyethyleneimine in acetone 5 times the total mass of the monomer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com