Manufacturing method of sulfur-silicon semiconductor alloy tandem solar cell

A technology of solar cells and semiconductors, applied in semiconductor/solid-state device manufacturing, semiconductor devices, circuits, etc., can solve problems such as high sheet resistance, large limitations, and long growth cycle, so as to improve processing efficiency and prevent external expansion and overflow , the effect of long growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

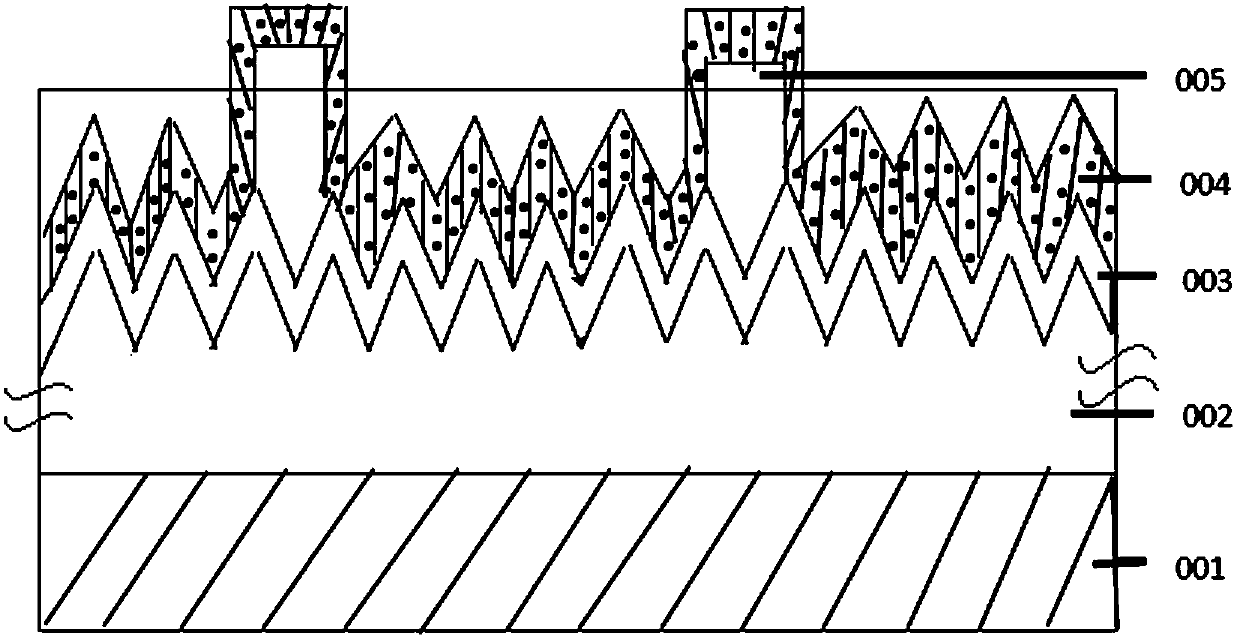

[0048] The present invention generates the structure of the submicron structure sulfur-silicon alloy laminated solar cell chip as follows figure 1 Shown:

[0049] 1. Al back field electrode,

[0050] 2. P-type Si layer,

[0051] 3. n-type Si layer,

[0052] 4. Sulfur-silicon semiconductor alloy layer (thickness 0.6µm),

[0053] 5. Collecting grid for commercial solar cell chips.

[0054] 1, 2, 3 and 5 are chip layers of commercial silicon-based solar cells.

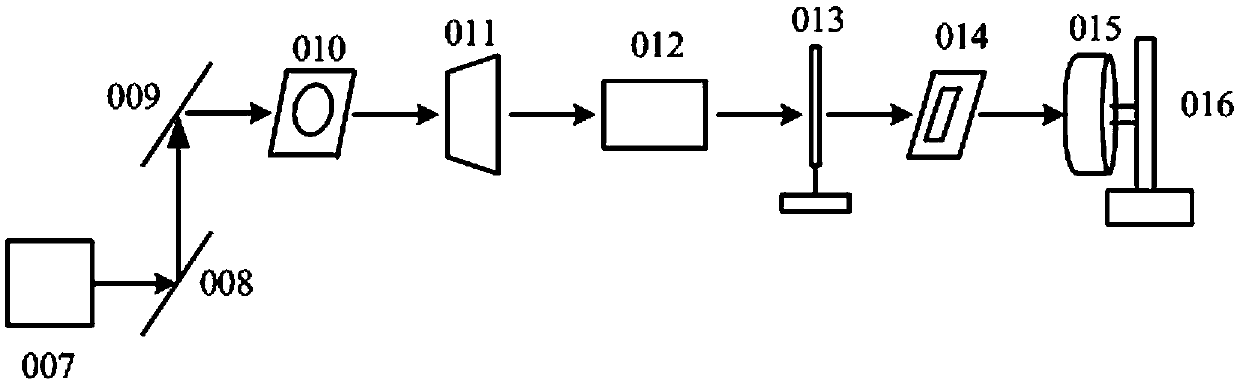

[0055] The structure of the laser band generating device of the present invention is as follows figure 2 Shown:

[0056] The laser band generation device sends laser light from the nanosecond laser 7 through the first and second 45-degree total reflection mirrors 8 and 9, the small hole 10, the beam expander 11, the attenuation sheet 12, the cylindrical mirror 13, and the rectangular hole 14 into the high The vacuum chamber 15 of the vacuum coating machine is connected with the double-frequency stepping workbench ...

Embodiment 2

[0073] The present invention generates the structure of a 2.6 μm sulfur-silicon alloy layer solar cell chip as follows figure 1 Shown:

[0074] 1. Al back field electrode,

[0075] 2. P-type Si layer,

[0076] 3. n-type Si layer,

[0077] 4. Sulfur-silicon semiconductor alloy layer (thickness 2.6µm),

[0078] 5. Collecting grid for commercial solar cell chips.

[0079] 1, 2, 3 and 5 are chip layers of commercial silicon-based solar cells.

[0080] The structure of the laser band generating device of the present invention is as follows figure 2 Shown:

[0081] The laser band generation device sends laser light from the nanosecond laser 7 through the first and second 45-degree total reflection mirrors 8 and 9, the small hole 10, the beam expander 11, the attenuation sheet 12, the cylindrical mirror 13, and the rectangular hole 14 into the high The vacuum chamber 15 of the vacuum coating machine is connected with the double-frequency stepping workbench 16.

[0082] 1. Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com