Polymer sand consolidating agent and preparation method thereof

A technology of sand consolidating agent and polymer, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problem of low sand consolidating strength and achieve the effect of enhancing the consolidating strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

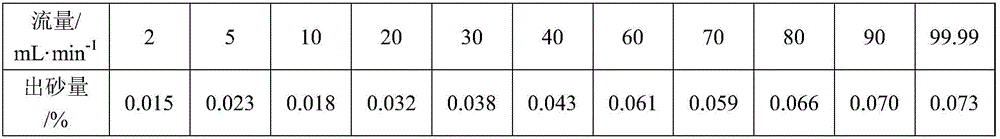

Embodiment 1

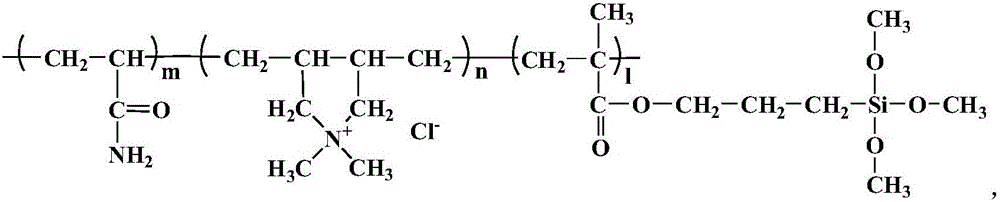

[0028] Example 1, acrylamide monomer was dissolved in water at 40°C to prepare acrylamide mother liquor with a concentration of 20%, and then dimethyl diallyl ammonium chloride, 3-(methacryloyloxy)propane Trimethoxysilane (KH570 / A174) and acrylamide mother liquor were mixed according to the mass ratio of 1:3:5, and the pH of the mixed solution was adjusted to 7.0. Nitrogen was passed through the mixed solution at a speed of 60mL / min to remove oxygen for 30min, and then ammonium persulfate / sodium bisulfite of 1% of the total monomer mass was added as an initiator, and placed in a water bath at 50°C for 1h to react, The obtained colloidal product was shredded, dried and pulverized to obtain a terpolymer of AM, DMDAAC and KH570 / A174. The molecular structure is:

[0029]

[0030] In the formula, m=14000-100000, n=6000-40000, l=6000-50000, and the molecular weight is 5-20 million.

[0031] The terpolymer of AM, DMDAAC and KH570 with a mass content of 2%, 1% ethylene glycol mon...

Embodiment 2

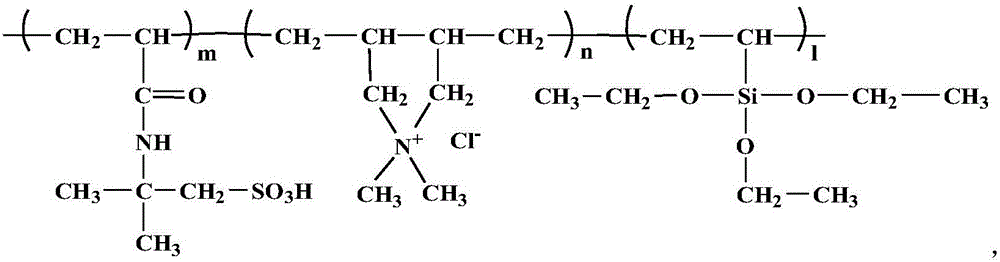

[0037] Example 2, 2-acrylamido-2-methylpropanesulfonic acid monomer was dissolved in water at 30°C to prepare a mother liquor with a concentration of 20%, and then dimethyl diallyl ammonium chloride, ethylene Triethoxysilane (A151) and 2-acrylamido-2-methylpropanesulfonic acid mother liquor were mixed according to the mass ratio of 1:1:5, and the pH of the mixed solution was adjusted to 6.5. Pass nitrogen gas to the mixed solution at a speed of 30mL / min to remove oxygen for 40min, then add potassium persulfate / sodium bisulfite with a total monomer mass of 0.5% as an initiator, and place it in a water bath at 60°C for 0.5h to react , the obtained colloidal product was shredded, dried and pulverized to obtain a terpolymer of AMPS, DMDAAC and A151. The molecular structure is:

[0038]

[0039] In the formula, m=5000-30000, n=6000-40000, l=8000-60000, and the molecular weight is 5-20 million.

[0040] Add 3% AMPS, DMDAAC and A151 terpolymer, 2% ethylene glycol dibutyl ether, ...

Embodiment 3

[0046] Example 3, acrylamide monomer was dissolved in water at 20°C to prepare a mother liquor with a concentration of 20%, and then dimethyl diallyl ammonium chloride, vinyltrimethoxysilane (A171) and acrylamide The mother liquor is mixed according to the mass ratio of 1:2:5, and the pH of the mixed solution is adjusted to 7.5. Pass nitrogen gas through the mixed solution at a rate of 10mL / min to remove oxygen for 15min, then add tert-butyl hydroperoxide / sodium metabisulfite with a total monomer mass of 0.1% as an initiator, and place it in a water bath at 30°C for 2h to react , the obtained colloidal product was shredded, dried and pulverized to obtain a terpolymer of AM, DMDAAC and A171. The molecular structure is:

[0047]

[0048] In the formula, m=14000-100000, n=6000-40000, l=10000-80000, and the molecular weight is 5-20 million.

[0049] Add the terpolymer of AM, DMDAAC and A171, 0.5% ethylene glycol dibutyl ether, and 1% hydrochloric acid with a mass content of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com