Compound fungicide FX for degrading straws and application thereof

A technology for compounding bacteria and straw, applied in the directions of bacteria, fungi, microorganism-based methods, etc., can solve the problems of high-temperature compost decomposing, and achieve the effect of promoting decomposing and decomposing, realizing recycling and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

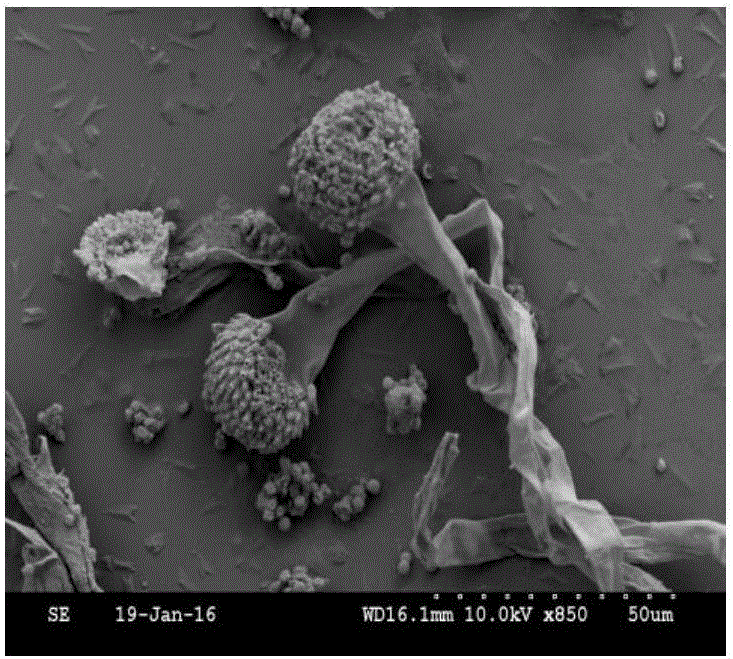

[0049] Screening of rice straw degrading strains:

[0050] The samples of degrading bacteria come from mixed organic materials at 50°C-70°C in the high temperature stage of industrial composting of Nanjing Mingzhu Fertilizer Co., Ltd., Baguazhou, Nanjing, Jiangsu Province. Weigh 10 g of the mixed sample, pass it through a liquid enrichment medium with rice straw powder as the only carbon source for one week (the liquid enrichment medium is: 2 g of rice straw powder dried to constant weight, crushed and passed through a 20-mesh sieve, added without Bacterial water 90ml) enrichment, after 2 days of enrichment, draw 10ml of enrichment solution and inoculate it into a new liquid enrichment medium to continue to cultivate the second generation, and so on to the third generation, draw 0.1ml to dilute and spread on On the Congo red medium, culture at 50°C for 3-7 days, select the strains that grow faster, especially those that can produce transparent circles, for isolation and purifi...

Embodiment 2

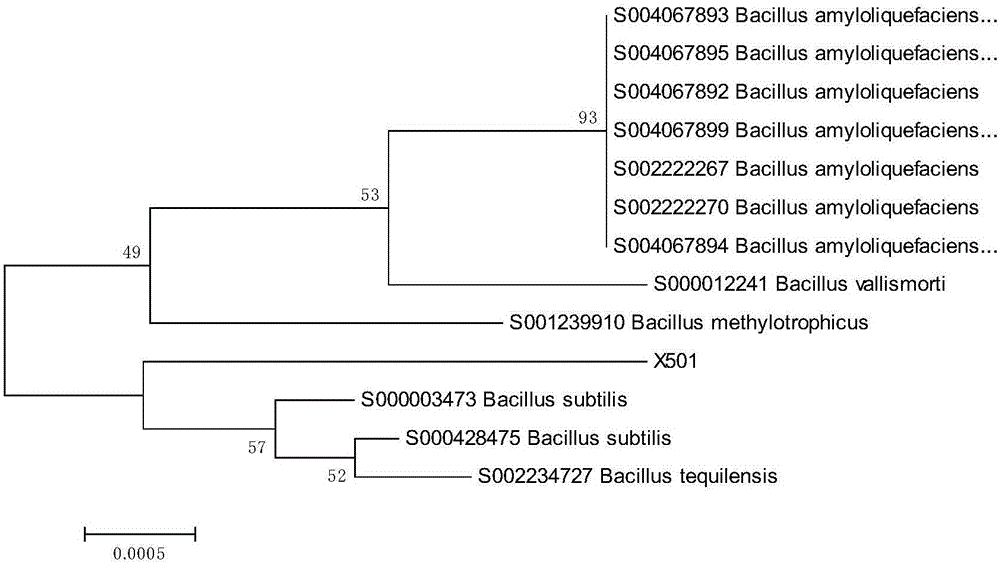

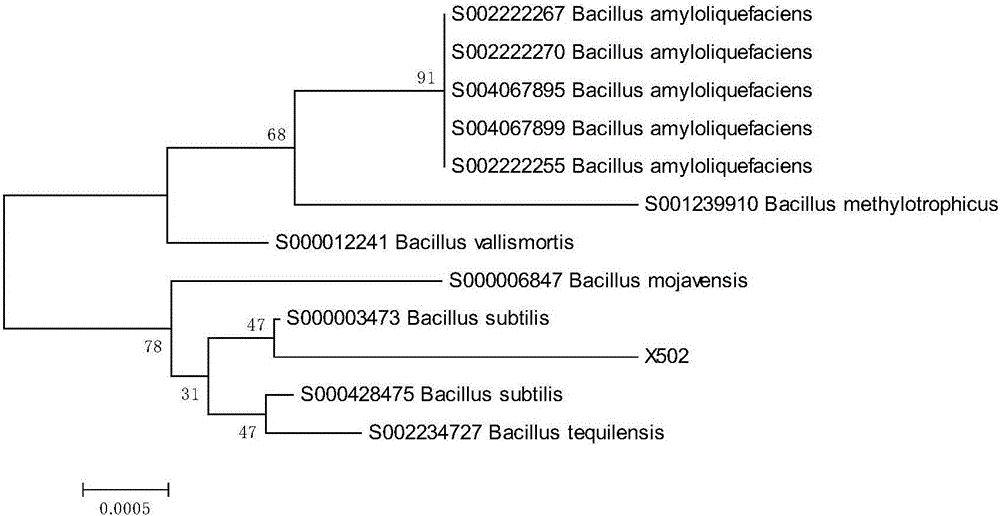

[0058] Example 2 Preparation of Rice Straw Degradation Compound Bacteria FX

[0059] Inoculate Bacillus subtilis strain NJX501, Bacillus subtilis strain NJX502, and methylotrophic Bacillus strain NJXy on LB medium separately, temperature 50°C, rotation speed 170rpm, shake culture for 1-2 days, remove supernatant after centrifugation Take the precipitate from the solution, and then resuspend it with 30ml of 0.9% sterilized normal saline to obtain the bacterial bacterium liquid, adjust the bacterial OD value of the bacterial bacterium liquid to 0.5; inoculate the Aspergillus fumigatus strain NJZ501 on the PDA medium, and culture it statically at 50°C For 4-7 days, shake with 20ml of 0.9% sterilized normal saline, and filter the culture to get the number of fungal spores 10 4The spore suspension of each / ml; the above-mentioned 3 bacterial bacterial liquids and fungal spore suspensions are mixed in equal volumes to obtain the compound bacterial agent FX.

[0060] LB medium is: pe...

Embodiment 3

[0062] Example 3 Determination of FX Enzyme Activity of Rice Straw Degradation Compound Strain

[0063] The bacterial bacterium liquid of 3 bacteria that embodiment 2 makes, the spore suspension of fungus, compound bacterial agent FX, respectively inoculate in the Erlenmeyer flask that 100ml rice stalk section culture medium is housed according to volume ratio 1%, 50 Under the condition of 170rpm shaking culture at 170rpm for 7 days and 15 days, samples were taken, and the fermentation broth was centrifuged at 8000rpm / min and 4°C for 5min; the crude enzyme liquid was obtained after filtering to remove bacteria and solid impurities, and the enzyme activity of filter paper (FPase) and cellulase ( CMCase) and xylanase activity (Xylanase).

[0064] Definition of enzyme activity: The definition of enzyme activity refers to the international standard, that is, the amount of enzyme that catalyzes the hydrolysis of the substrate to generate 1 μmol reducing sugar within 1 minute under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com