Low-temperature coal tar pretreatment technology

A low-temperature coal tar and pretreatment technology, which is applied in the direction of multi-stage series refining process, can solve the problems of difficult power supply, high operating costs, and complicated process, so as to improve the effect of pretreatment and prevent corrosion of equipment , the effect of reducing the content of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

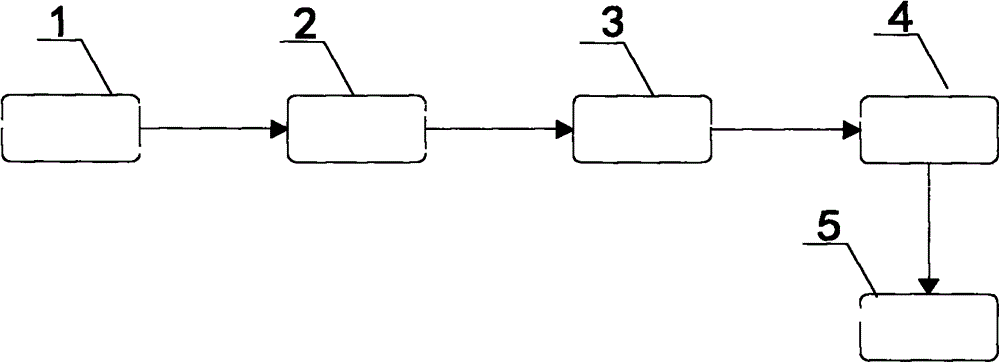

Method used

Image

Examples

Embodiment 1

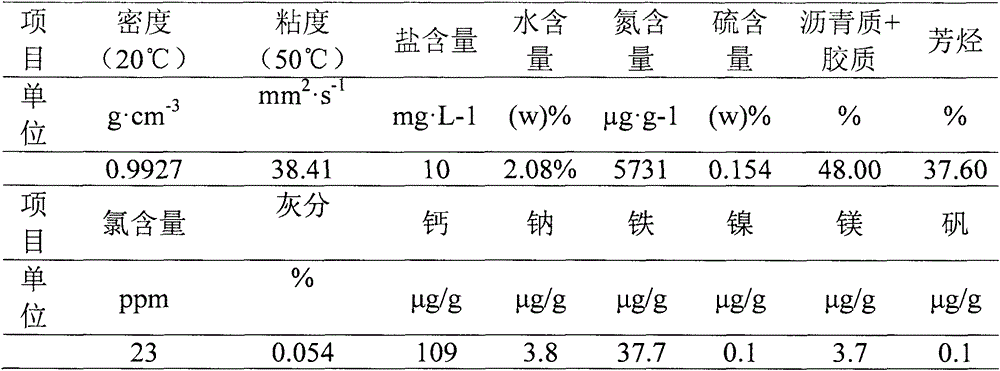

[0023] Coal tar is a black wax, opaque, with a pungent and unpleasant smell. The analysis results of coal tar properties are shown in Table 1.

[0024] As can be seen from Table 1, the coal tar is a low-quality oil product with high density, heavy fraction, high nitrogen content, low sulfur content, high content of colloids, asphaltenes, and aromatics, and coal tar contains a large amount of oil that is not conducive to subsequent Hydrotreated impurity elements. The coal tar has a water content of about 2%, a salt content of 10 mg / L, and a relatively high calcium and iron content in the metal content, which are 109 μg / g and 38 μg / g, respectively.

[0025] Table 1 Properties of coal tar

[0026]

[0027] Taking the processing of the low-temperature coal tar as an example, the specific process implementation steps are described in detail:

[0028] The coal tar is heated to 60°C, the coal tar is settled and separated in the storage tank, and part of the waste water can be d...

Embodiment 2

[0033] The raw material oil of treatment is still the low-temperature coal tar in embodiment 1, and this coal tar is directly processed by this process technology without blending light oil process, and its specific process implementation steps are described in detail below:

[0034]Heat the coal tar to 70°C, the coal tar will be settled and separated in the storage tank, and part of the waste water can be discharged from the bottom. After pumping out the raw material oil, inject 30 μg / g of demulsifier and 100 μg / g of dechlorination agent into the pipeline before the mixer. Inject 15% by weight of fresh water, mix with coal tar in the mixer, enter the heat exchanger through the pipeline to exchange heat to 80 ° C, enter the three-phase centrifuge for high-speed centrifugation, and the centrifugal speed is 4500r / min; after centrifugation, It can remove most solid impurities and salts, including ammonium chloride and ammonium thiocyanate; at the same time, it can also separate mo...

Embodiment 3

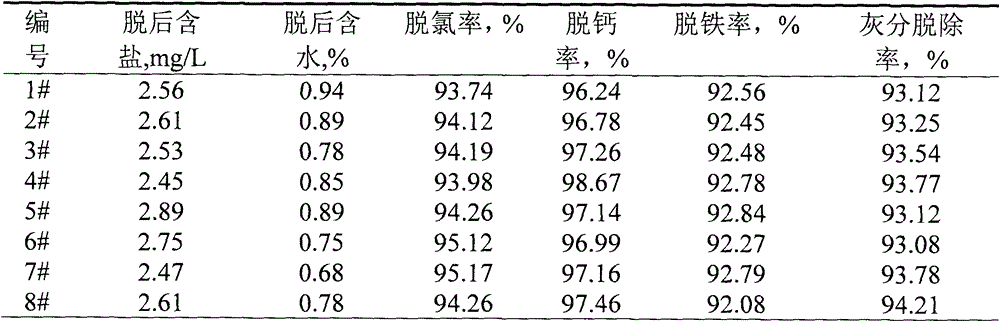

[0039] The raw material oil treated is still the low-temperature coal tar in Examples 1 and 2, and the mixed diesel oil at 200-300°C is selected as the blended hydrocarbon oil, wherein the diesel fraction at 200-220°C accounts for 20%wt, and 220-240°C accounts for 20% wt, 240-260°C accounts for 20%wt, 260-280°C accounts for 20%wt, and 280-300°C accounts for 20%wt.

[0040] The diesel oil is blended in different proportions, and the influence of the blending ratio on the pretreatment effect of coal tar is investigated. The specific process implementation steps are described in detail below:

[0041] First heat the coal tar to 75°C, the coal tar settles and separates in the storage tank, and part of the waste water can be discharged from the bottom, and then the coal tar and diesel oil are respectively in the volume ratio of 10:0.5, 10:1.0, 10:1.5, 10:2.0 , 10:2.5, 10:3.0 blending, use the raw oil pump and the blending oil pump to pump out and mix in the mixer, enter the heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com