Method for modifying nickel lithium manganate material of lithium-ion battery

A lithium-ion battery, lithium nickel manganese oxide technology, applied in the field of battery material preparation and modification, can solve the problems of restricting battery performance, difficult to control environmental moisture, and high battery moisture content, improving cycle and rate performance, and improving the first Coulombic efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

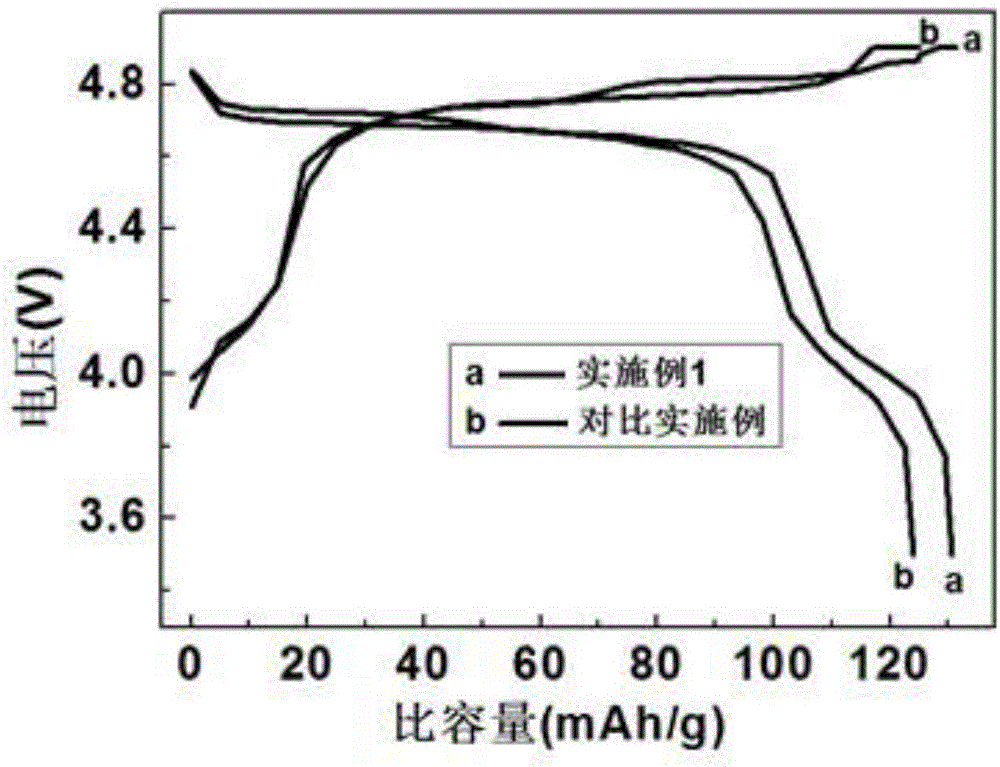

Embodiment 1

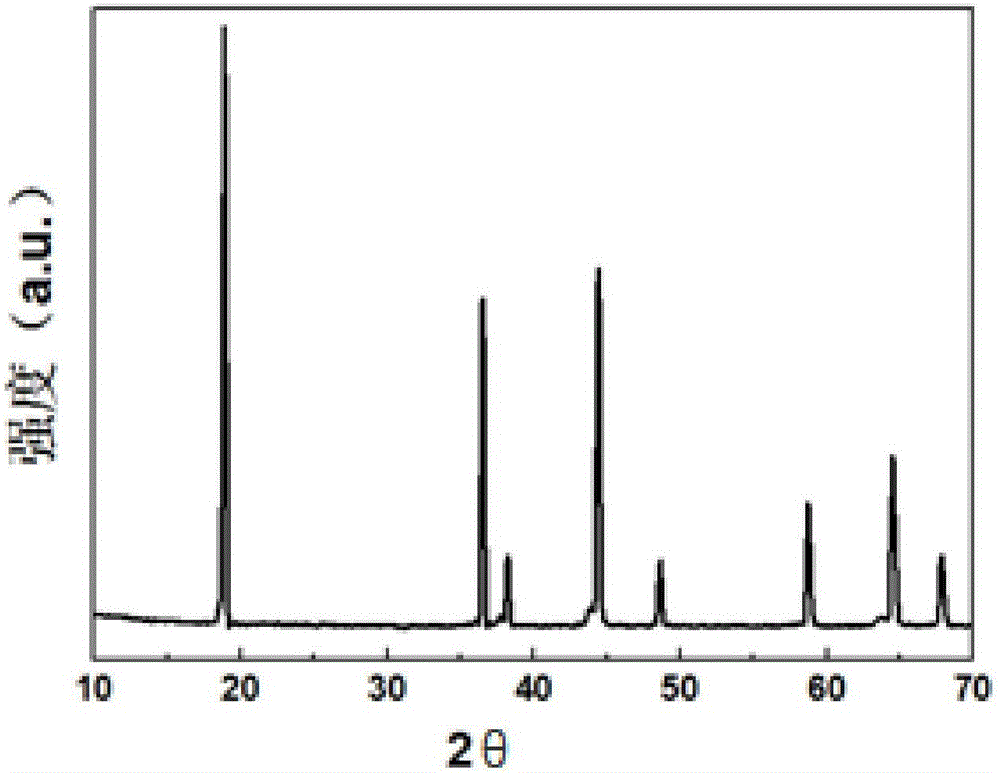

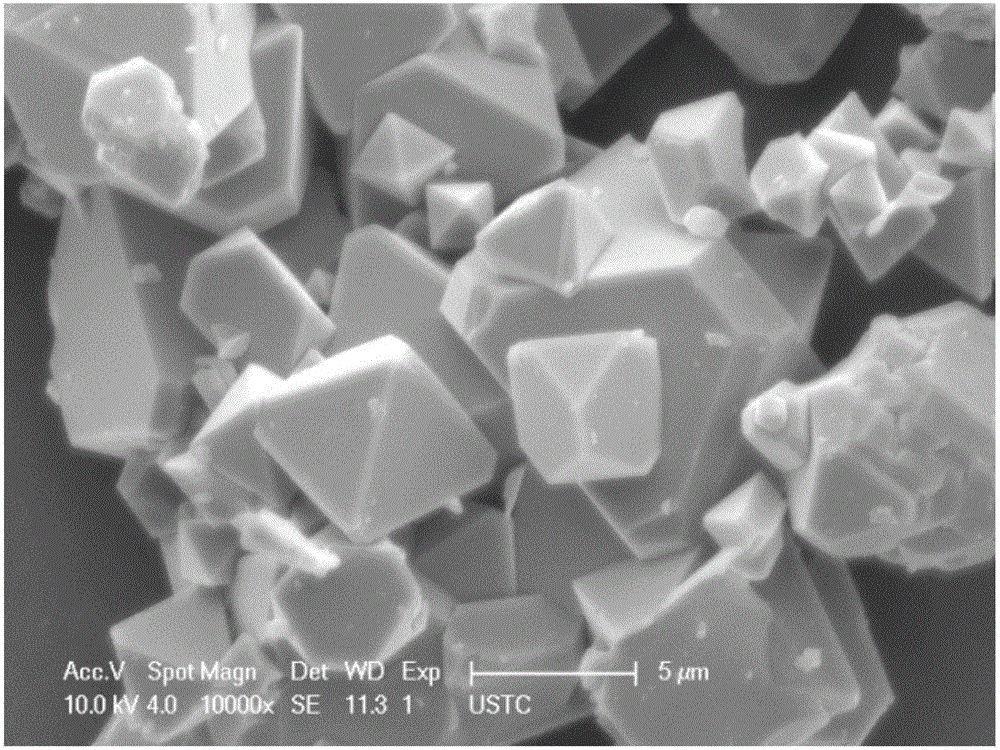

[0025] (1) Preparation of pure-phase lithium nickel manganate precursor: Accurately weigh lithium acetate, nickel sulfate and manganese sulfate according to the Li:Ni:Mn element ratio of 2:1:3, fully dissolve them in deionized water, and slowly add them to the solution. In the ultrasonic citric acid aqueous solution, the amount of citric acid added is 1% of the theoretically synthesized lithium nickel manganate mass fraction. The solution was reacted under reflux at 60°C for 2h, and a sol was formed. The sol was dried at 100°C to form a green xerogel. After grinding, it was pre-fired for 3h in an air atmosphere of 400°C. After natural cooling, the pure phase nickel-manganese was obtained. Lithium oxide precursor;

[0026] (2) Accurately weigh strontium nitrate, ferric nitrate, and ammonium molybdate according to Sr:Fe:Mo=2:1:1, add them to deionized water, and then add nitric acid 1 times the amount of ammonium molybdate to make it The solution is completely dissolved; the li...

Embodiment 2

[0036](1) Preparation of pure-phase nickel manganate precursor: Accurately weigh lithium nitrate, nickel nitrate, and manganese nitrate according to the Li:Ni:Mn element ratio of 2.03:1:3, fully dissolve them in deionized water, and slowly add them to In the ultrasonic citric acid aqueous solution, the amount of citric acid added is 2% of the theoretical synthesis of lithium nickel manganate, the solution is reacted at 65 °C for 3 hours under reflux conditions, and a sol is formed. The sol is dried at 100 °C to form a green dry Gel, after grinding, pre-fired for 3.5 hours in an air atmosphere of 450 °C, naturally cooled and taken out to obtain a pure phase lithium nickel manganate precursor;

[0037] (2) Accurately weigh strontium nitrate, ferric nitrate, and ammonium molybdate according to Sr:Fe:Mo=2:1:1, add them to deionized water, and then add nitric acid 1.5 times the amount of ammonium molybdate to make it The solution is completely dissolved; the lithium nickel manganat...

Embodiment 3

[0041] (1) Preparation of pure phase nickel manganate precursor: Lithium acetate, nickel chloride and manganese chloride are accurately weighed and fully dissolved in deionized water according to the Li:Ni:Mn element stoichiometric ratio of 2.05:1:3. It was added to the ultrasonic citric acid aqueous solution, wherein the amount of citric acid added was 2% of the mass fraction of theoretically synthesized lithium nickel manganate. The solution was reacted at 70 °C for 5 hours under reflux conditions, and a sol was formed. The sol was dried at 110 °C to form Green xerogel, after grinding, pre-fired in an air atmosphere of 500 °C for 4 hours, and then naturally cooled and taken out to obtain a pure phase lithium nickel manganate precursor;

[0042] (2) Accurately weigh strontium nitrate, ferric nitrate, and ammonium molybdate according to Sr:Fe:Mo=2:1:1, add them into deionized water, and then add nitric acid twice the amount of ammonium molybdate to make them The solution is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com