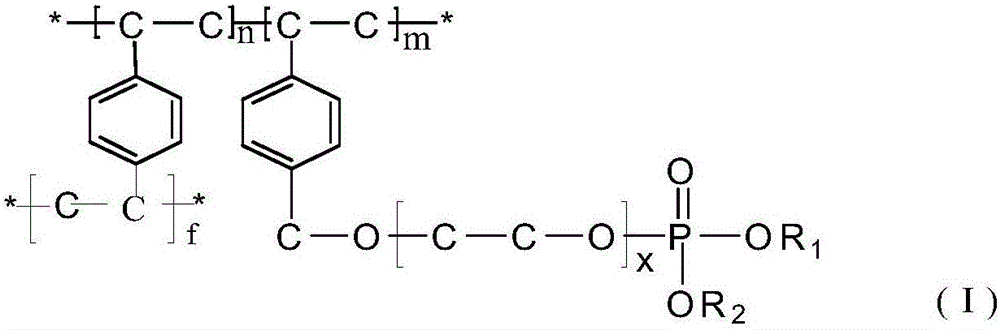

Phosphorus-containing efficient metal ion adsorbing materials and preparation method thereof

A metal ion and adsorption material technology is applied to a type of phosphorus-containing high-efficiency metal ion adsorption material and its preparation field, which can solve the problems of equipment corrosion, poor production environment and high requirements, and achieve stable adsorption performance and simple modification method. , the effect of saving the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0033] Seawater used in Example 3 was directly taken from the coast of Lianyungang.

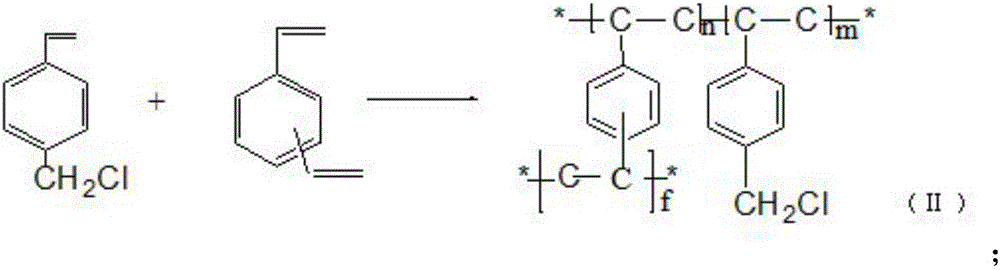

Embodiment 1

[0035] a) Styrene skeleton synthesis: 0.5g benzoic acid peroxide, 100g vinylbenzyl chloride and 2g vinylpyridine, suspension polymerization, after the reaction, extract with toluene, concentrate, sieve, select 250 ~ 425mm particle size product;

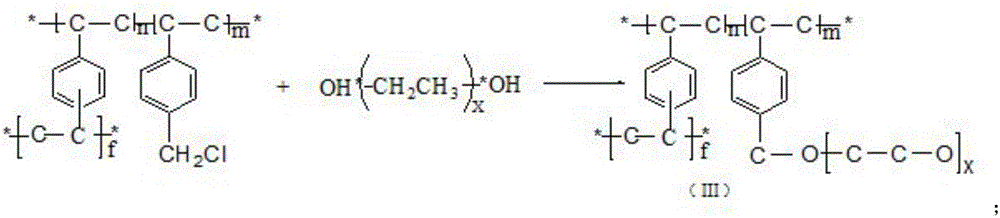

[0036] b) graft alcoholization: 10gNaH (content 60%) slowly adds 50g ethylene glycol, and adds 50ml dioxane, feeds N 2 Protect and keep warm for 2h (about 30-60°C); at the same time, take a certain amount of 10g intermediate product (II) and swell it in 40ml dioxane solution for 2h; add the intermediate product (II) swelling solution into the NaH reaction system, Reflux reaction for 20 hours, the product was washed with acetone, dioxane / acetone (1:1) and water in sequence, and dried in vacuum at 70°C for 12 hours;

[0037] c) Phosphating reaction: add 50ml of 3-picoline to 2g of the intermediate product (Ⅲ), stir at room temperature for 2h, add 10ml of ethyl chlorophosphate, reflux for 12h to react, remove the solvent after completio...

Embodiment 2

[0041] a) Styrene skeleton synthesis: as in Example 1;

[0042] b) graft alcoholization: 10gNaH (content 60%) slowly adds 100g triethylene glycol, and adds 100ml dioxane, feeds N 2 protection, heat preservation reaction for 2 hours; at the same time, take a certain amount of 10g intermediate product (II) and swell it in 40ml dioxane solution for 2 hours; Wash with oxane, dioxane / water (1:1) and water in sequence, and dry in vacuum at 70°C for 12 hours;

[0043] c) Phosphating reaction: add 50ml of 4-dimethylaminopyridine to 2g of intermediate product (Ⅲ), stir at room temperature for 2h, add 10ml of methyl chlorophosphate, reflux for 5h to react, remove solvent after completion, wash with ethanol and water for 3 times respectively, Wash the product with 5% sodium hydroxide, water, and 5% hydrochloric acid solution in turn, and finally wash with water until neutral to obtain the product;

[0044] d) Take 10g of adsorption material, statically adsorb the prepared U(VI), Lu(III...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com