Polyarylether resin containing carboxyl group and preparing method thereof

A polyarylene ether and carboxyl technology, applied in the field of polymers, can solve the problems of low glass transition temperature and need to improve mechanical properties, and achieve the advantages of simple preparation method, good flame retardancy and solubility, excellent temperature resistance and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a kind of preparation method of carboxyl-containing polyarylether resin of the present invention, comprising:

[0047] The phenolphthalein monomer, HO-Ar 2 -OH, bis(4-halophenyl)phenylphosphine oxide, X-Ar 1 -X and the solvent are mixed and reacted to obtain carboxyl-containing polyarylether resin;

[0048] Among them, the Ar 1 C5-C50 unsubstituted arylene group, C5-C50 substituted arylene group, C5-C50 carbonyl-containing arylene group, C5-C50 sulfone-containing arylene group;

[0049] The Ar 2 C5-C50 unsubstituted arylene group, C5-C50 substituted arylene group, C5-C50 carbonyl-containing arylene group, C5-C50 sulfone-containing arylene group;

[0050] X is halogen.

[0051] In the preparation method of the present invention, the present invention has no special requirements on the source of raw materials, wherein:

[0052] The HO-Ar 2 -OH, the Ar 2 It is preferably C6-C30 unsubstituted arylene group, C6-C30 substituted aryl...

Embodiment 1

[0066] Add 3.2034 grams (0.01mol) of phenolphthalein and 3.1427 grams (0.01mol) of bis(4-fluorophenyl)phenyl to a 100ml three-necked flask equipped with a nitrogen conduit, a condenser, a water separator, a thermometer and a mechanical stirrer. Phosphine oxide, 2.0732 g (0.015 mol) of anhydrous potassium carbonate, 18 ml of sulfolane and 20 ml of toluene. Raise the temperature to 130°C for azeotropic dehydration. After about 3 hours, distill all the toluene off, continue to heat up to 220°C for 4 hours, and precipitate the polymer solution in a mixed solvent with a volume ratio of ethanol and concentrated hydrochloric acid of 10:1. Use distilled water to boil and wash repeatedly to remove inorganic salts and solvents, and obtain carboxyl-containing polyarylether resin after drying.

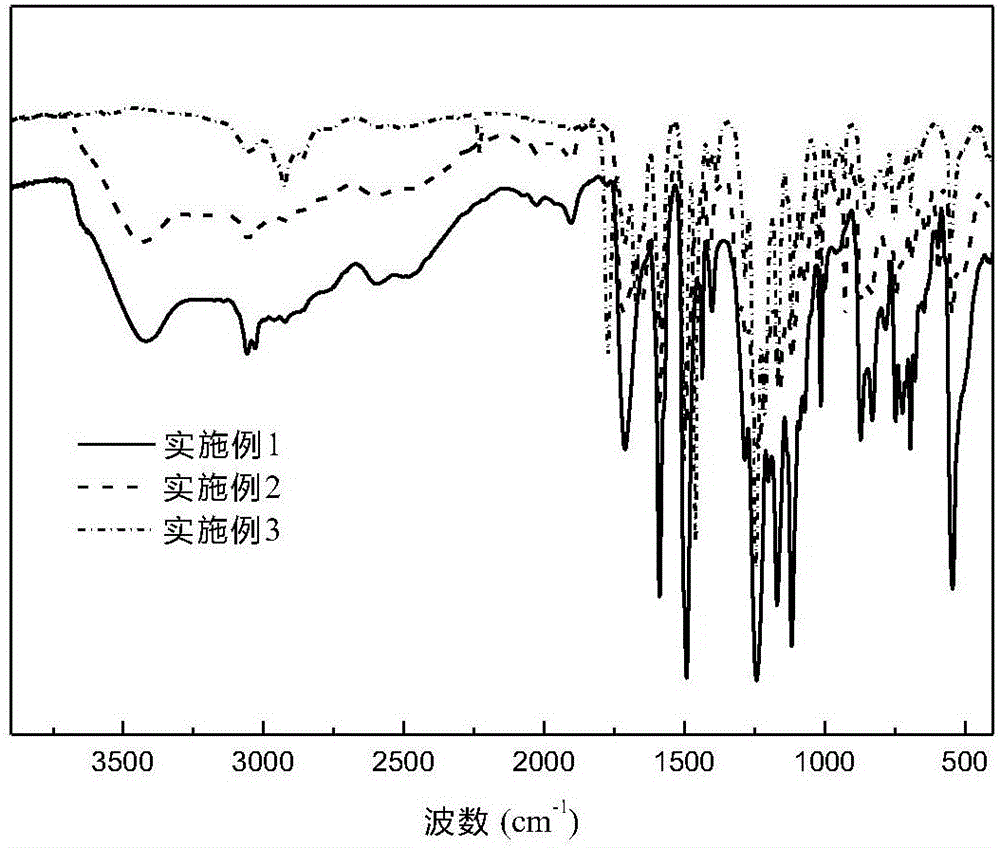

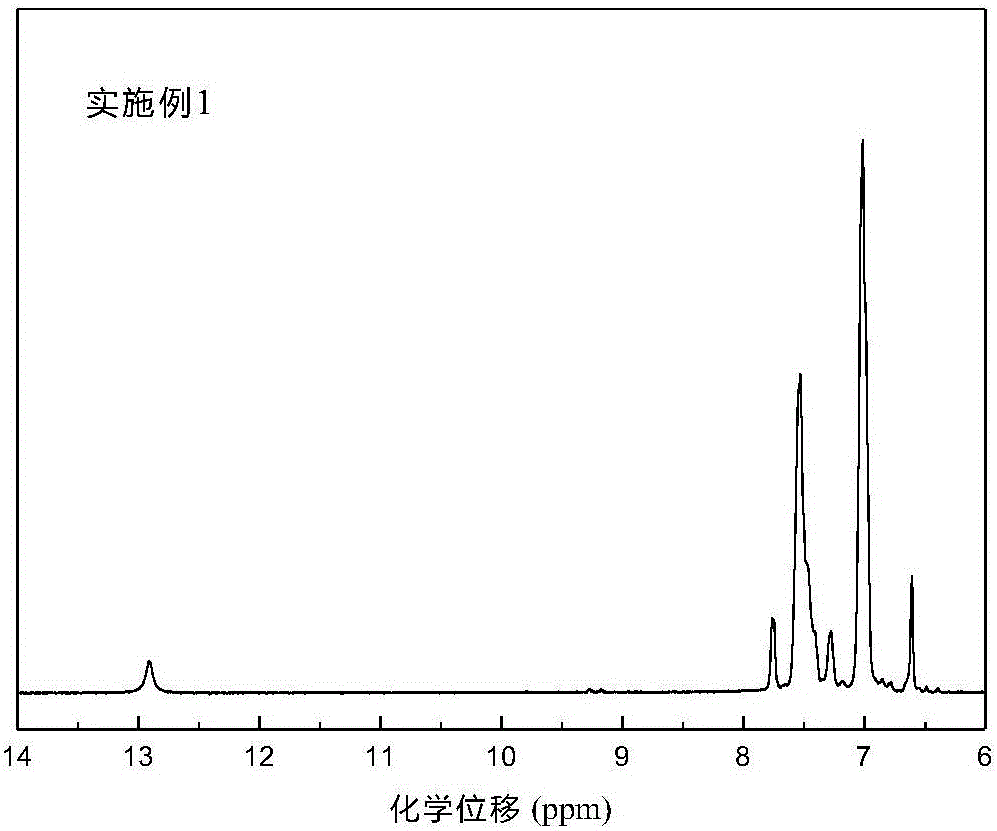

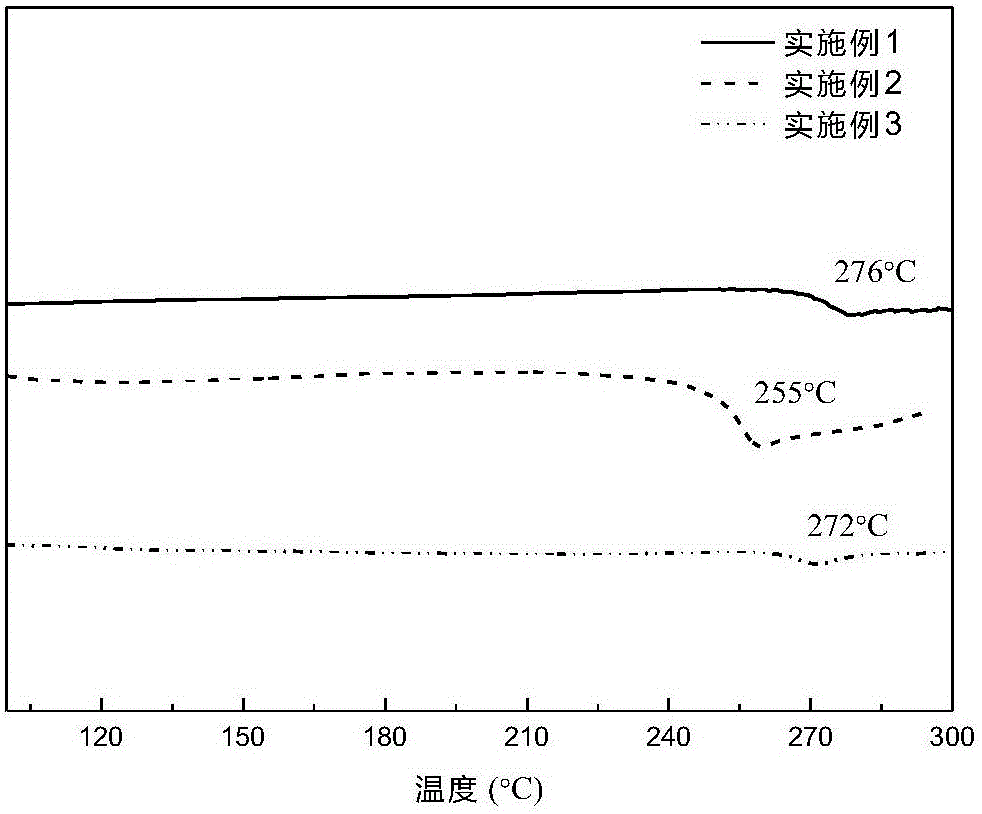

[0067] Structural identification of the obtained polymer was carried out, the results are shown in figure 1 and figure 2 , figure 1 Infrared spectra of carboxyl-containing polyarylether resins...

Embodiment 2

[0073] Add 3.2034 grams (0.01mol) of phenolphthalein and 1.5714 grams (0.005mol) of bis(4-fluorophenyl)phenyl to a 100ml three-necked flask equipped with a nitrogen conduit, a condenser, a water separator, a thermometer and a mechanical stirrer. Phosphine oxide, 1.091 g (0.005 mol) 4,4'-difluorobenzophenone, 2.7642 g (0.02 mol) anhydrous potassium carbonate, 16 ml dimethylsulfoxide and 20 ml toluene. Raise the temperature to 130°C, azeotropic dehydration, after about 2 hours, distill all the toluene, continue to heat up to 175°C for 8 hours, put the polymer solution in a mixed solvent of deionized water and concentrated hydrochloric acid with a volume ratio of 10:1 Precipitate, wash with distilled water repeatedly to remove inorganic salts and solvents, and obtain carboxyl-containing polyarylether resin after drying.

[0074] Structural identification of the obtained polymer was carried out, the results are shown in figure 1 and Figure 4 , figure 1 Infrared spectra of carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com