Nitride epitaxial growth technology adopting AlON buffer layer

An epitaxial growth and nitride technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., to achieve the effect of low dislocation density, high crystal quality and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A specific embodiment of the epitaxial growth technology of nitride using AlON buffer layer and the nitride epitaxial growth using this technology provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

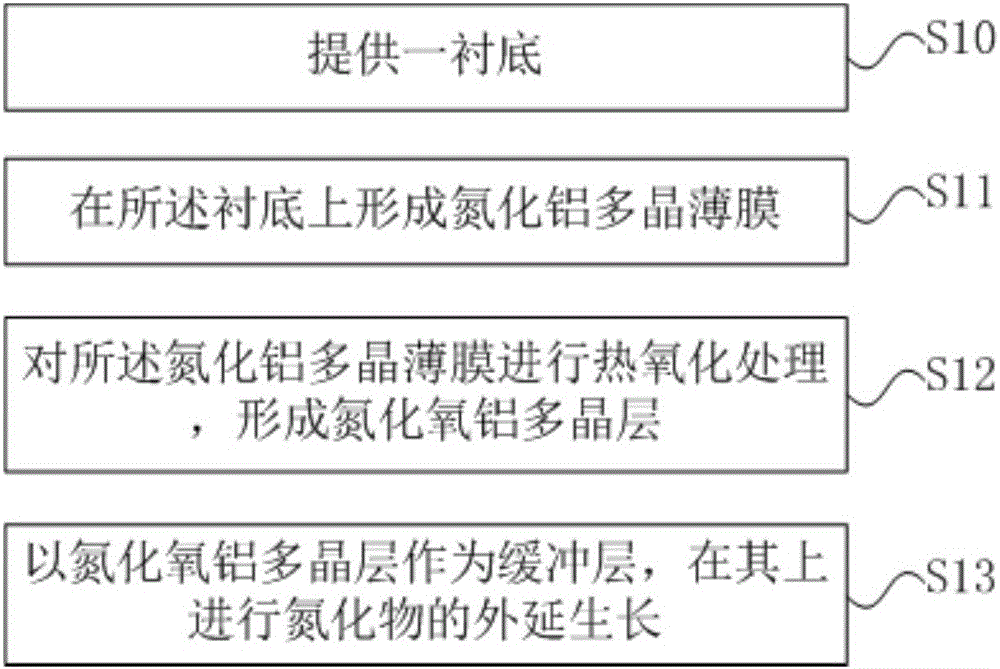

[0020] see figure 1 , a kind of epitaxial growth technology of the nitride that adopts AlON buffer layer of the present invention comprises the following steps: Step S10, provide a substrate; Step S11, form aluminum nitride polycrystalline thin film on described substrate; Step S12, for all The aluminum nitride polycrystalline film is thermally oxidized to form an aluminum oxynitride polycrystalline layer; step S13 , using the aluminum oxynitride polycrystalline layer as a buffer layer, and performing epitaxial growth of nitride thereon.

[0021] Figure 2A ~ Figure 2D It is a process flow chart of a nitride epitaxial growth technology using an AlON buffer layer in the present invention.

[0022] See step S10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com