Formula feed for feeding sepiella maindroni

A technology of needle-free cuttlefish and formula feed, which is applied in animal feed, animal feed, application, etc., can solve the problems of easily polluted water quality, difficult storage, low utilization rate, etc., to alleviate resource crisis, reduce impact, and reduce environmental pollution. The effect of pollution load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

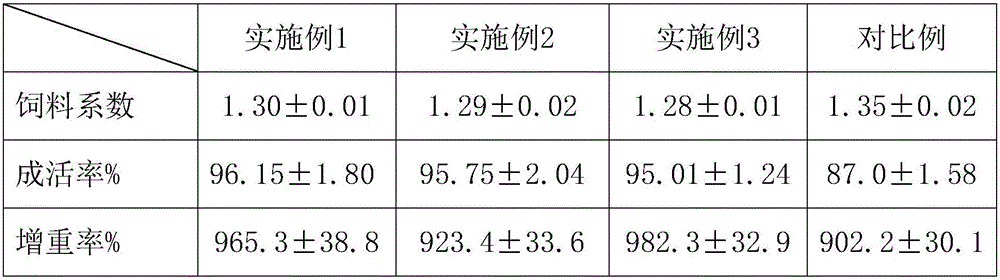

Examples

Embodiment 1-3

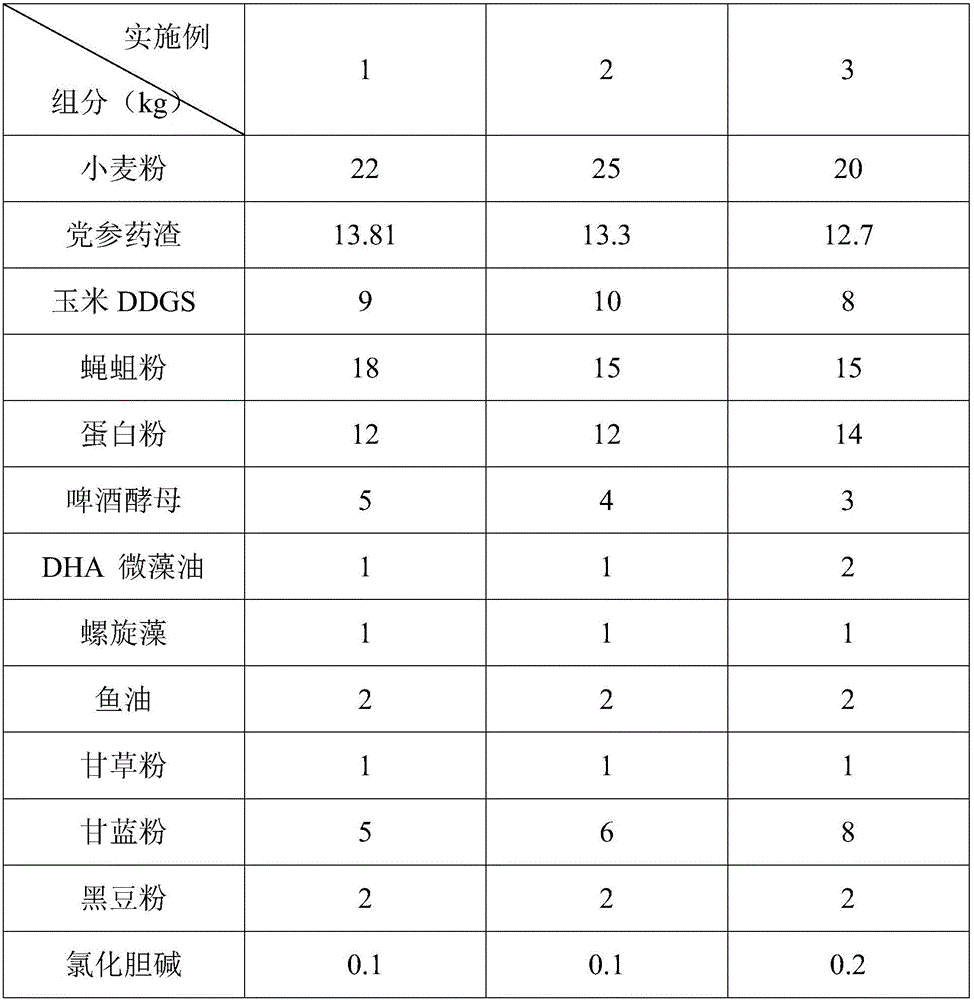

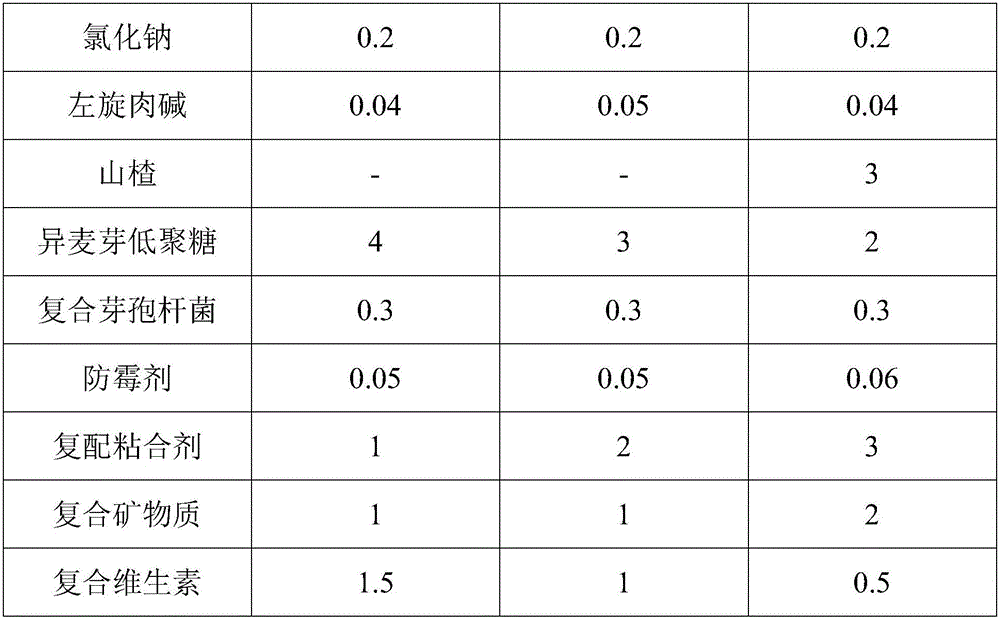

[0029] A kind of needleless cuttlefish compound feed, its raw materials are shown in Table 1.

[0030] Table 1

[0031]

[0032]

[0033] The above-mentioned components are mixed and passed through an 80-mesh standard sieve, then water is added to make soft granules, and the water content of the formula feed is controlled to be ≤12%.

Embodiment 1

[0035] The composition of multivitamin is: every 1000g of multivitamin contains vitamin A12000000IU, vitamin D 3 2500000IU, vitamin E100000IU, vitamin K 3 9000mg, Vitamin B 1 20000mg, vitamin B 2 25mg, niacin 70,000mg, calcium pantothenate 25,000mg, folic acid 2,500mg, biotin 250mg, inositol 100,000mg, vitamin C 200,000mg, and the rest is bran. The composition of the composite adhesive is: every 1000g of the composite adhesive contains 300g of gluten powder, 400g of seaweed glue, 200g of tamarind seed glue, and 100g of dextrin. The composition of compound minerals is: every 1000g of compound minerals contains 25000mg of iron, 4000mg of manganese, 2000mg of copper, 7000mg of zinc, 600mg of cobalt, 3500mg of iodine, 125mg of selenium, 55000mg of magnesium, 30000mg of potassium, and the rest is medical stone.

Embodiment 2

[0037] The composition of multivitamin is: every 1000g multivitamin contains vitamin A10000000IU, vitamin D 3 2000000IU, vitamin E80000IU, vitamin K 3 6000mg, vitamin B 1 10000mg, Vitamin B 2 20mg, niacin 60,000mg, calcium pantothenate 20,000mg, folic acid 2,000mg, biotin 200mg, inositol 80,000mg, vitamin C 150,000mg, and the rest is bran. The composition of the composite adhesive is: every 1000g of the composite adhesive contains 250g of gluten powder, 350g of seaweed glue, 250g of tamarind seed glue, and 150g of dextrin. The composition of compound minerals is: every 1000g compound compound minerals contains iron 20000mg, manganese 3000mg, copper 1500mg, zinc 6000mg, cobalt 500mg, iodine 3000mg, selenium 100mg, magnesium 50000mg, potassium 25000mg, and the rest is medical stone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com