Method for treating recycled livestock and poultry breeding wastewater by aid of forward osmosis membrane bioreactors

A technology of livestock and poultry breeding wastewater and bioreactor, which is applied in the field of water treatment, can solve problems such as not being suitable for use in livestock farms, hindering the sustainable development of the breeding industry, and affecting the effect of aerobic treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

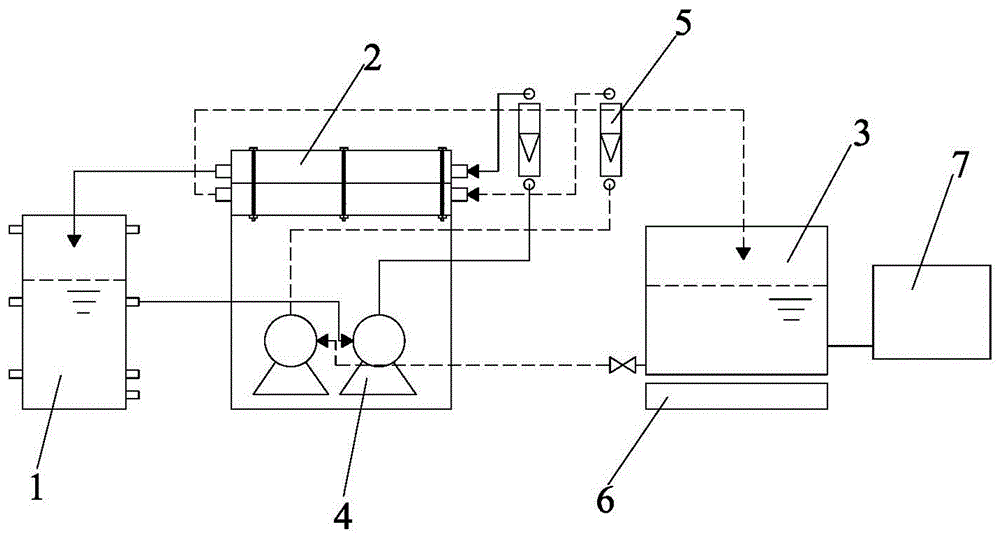

[0020] Put 4LCOD concentration of 3330.46mg / L, TN500mg / L, TP100mg / L of livestock and poultry wastewater into bioreactor 1, and carry out biodegradation reaction under the condition of activated sludge concentration of 3000mg / L for 60min. The raw material liquid treated by the bioreactor 1 is transported to the forward osmosis membrane module 2 through the pressure pump module 4 and the flow meter 5 for sludge-water separation. The draw liquid is stored in the draw liquid tank 3 , and the draw liquid in the draw liquid tank 3 enters the forward osmosis membrane module 2 through the pressure pump assembly 4 and the flow meter 5 .

[0021] In this embodiment, the forward osmosis membrane module 2 operates in the mode that the active layer faces the draw solution, the draw solution is magnesium chloride, and the concentration of the draw solution is 1.00 mol / L. Under these conditions, the removal rate of TOC in livestock and poultry wastewater was 95%, the removal rate of TN was 9...

Embodiment 2

[0024] Embodiment 2 is different from Embodiment 1 in: 4LCOD concentration 2000mg / L, TN500mg / L, TP100mg / L livestock and poultry waste water is placed in bioreactor, under the condition that activated sludge concentration is 1000mg / L, carry out biological Degradation reaction 60min. The effluent from the bioreactor passes through the forward osmosis membrane module for mud-water separation. The forward osmosis membrane module operates in the mode that the active layer faces the raw material solution, the draw solution is sodium chloride, and the concentration of the draw solution is 1.00mol / L. Under these conditions, the removal rate of TOC in livestock and poultry wastewater was 87%, the removal rate of TN was 84%, and the removal rate of TP was 98%.

Embodiment 3

[0026] Embodiment three is different from embodiment one in that: 4LCOD concentration 5000mg / L, TN500mg / L, TP100mg / L livestock and poultry waste water is placed in bioreactor, under the condition that activated sludge concentration is 4000mg / L, carry out biological Degradation reaction 60min. The effluent from the bioreactor passes through the forward osmosis membrane module for mud-water separation. The forward osmosis membrane module operates in the mode that the active layer faces the draw solution, the draw solution is magnesium chloride, and the concentration of the draw solution is 1.00mol / L. Under these conditions, the removal rate of TOC in livestock and poultry wastewater was 85%, the removal rate of TN was 90%, and the removal rate of TP was 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com