Method for manufacturing photocatalyst diatom ooze light high-strength plate

The technology of diatom mud and high-strength board is applied in the field of building materials, which can solve the problems of non-inhibition of bacterial reproduction, complicated process, inorganic fire-proof thermal insulation rock mud and calcium silicate board do not have the removal function, etc. Scientific formula, good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 A kind of method for making of light-weight high-strength board of photocatalyst diatom mud, its steps and conditions are as follows:

[0037] The light-weight high-strength board of a kind of photocatalyst diatom mud is made of substrate and photocatalyst layer coated on the surface of substrate;

[0038] The composition and mass percentage of the substrate are as follows:

[0039] (ⅰ) Tertiary algal earth: 40%;

[0040] (ii) quicklime: 15%;

[0041] (ⅲ) Cement: 30%;

[0042] (ⅳ) Reinforcing fiber: 15%;

[0043] The composition and mass percentage of described photocatalyst layer are as follows:

[0044] (a) Graphite phase carbon nitride: 0.3%;

[0045] (b) Surfactant: 10%;

[0046] (c) Adhesive: 0.1%; the balance is water.

[0047] The reinforcing fiber is wood pulp;

[0048] The particle size of the graphite phase carbon nitride is 50μ;

[0049] Described surfactant is polyethylene glycol;

[0050] The binder is polyvinyl alcohol.

[0051] Des...

Embodiment 2

[0065] Embodiment 2 A kind of preparation method of photocatalyst diatom ooze light weight high-strength board, its steps and conditions are as follows:

[0066] The light-weight high-strength board of a kind of photocatalyst diatom mud is made of substrate and photocatalyst layer coated on the surface of substrate;

[0067] The composition and mass percentage of the substrate are as follows:

[0068] (ⅰ) Tertiary algal earth: 50%;

[0069] (ii) Quicklime: 10%;

[0070] (ⅲ) Cement: 20%;

[0071] (ⅳ) Reinforcing fiber: 20%;

[0072] The composition and mass percentage of described photocatalyst layer are as follows:

[0073] (a) Graphite phase carbon nitride: 5%;

[0074] (b) Surfactant: 5%;

[0075] (c) Adhesive: 3%; the balance is water.

[0076] The reinforcing fiber is straw paddle;

[0077] The particle size of the graphite phase carbon nitride is 5μ;

[0078] Described surfactant is polyethylene glycol;

[0079] The adhesive is 108 glue.

[0080] The preparatio...

Embodiment 3

[0085] Embodiment 3 A kind of method for making of photocatalyst diatom ooze light weight high-strength board, its steps and conditions are as follows:

[0086] The light-weight high-strength board of a kind of photocatalyst diatom mud is made of substrate and photocatalyst layer coated on the surface of substrate;

[0087] The composition and mass percentage of the substrate are as follows:

[0088] (ⅰ) Tertiary algal earth: 45%;

[0089] (ii) quicklime: 13%;

[0090] (ⅲ) Cement: 25%;

[0091] (ⅳ) Reinforcing fiber: 17%;

[0092] The composition and mass percentage of described photocatalyst layer are as follows:

[0093] (a) Graphite phase carbon nitride: 3%;

[0094] (b) Surfactant: 10%;

[0095] (c) Adhesive: 5%; the balance is water. The preparation method is the same as in Example 1.

[0096] The composition and mass percentage of described photocatalyst layer are as follows:

[0097] (a) Graphite phase carbon nitride: 0.3-5%;

[0098] (b) Surfactant: 0.2-10%; ...

PUM

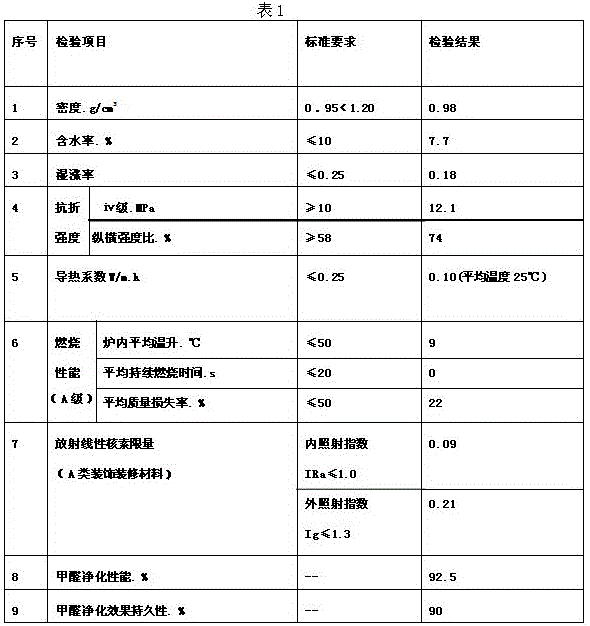

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com