Method of preparing 4H-SiC metal semiconductor field effect transistor with part highly-doped channel

A highly doped, effect transistor technology, used in semiconductor/solid-state device manufacturing, transistors, semiconductor devices, etc., can solve problems such as saturation current degradation, saturation leakage current is not substantially improved, lattice damage, etc., and achieve a good barrier. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

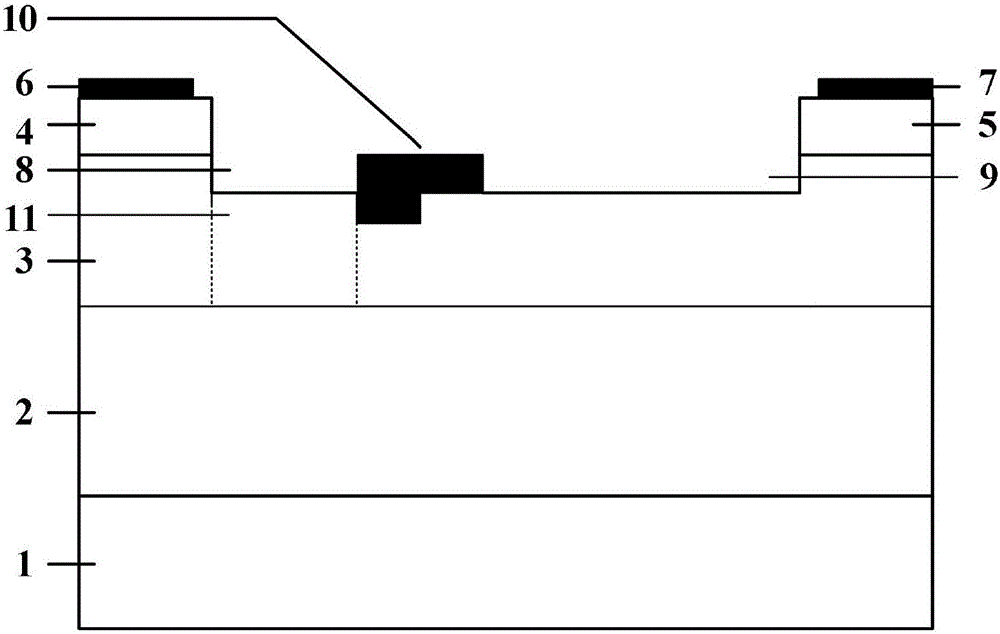

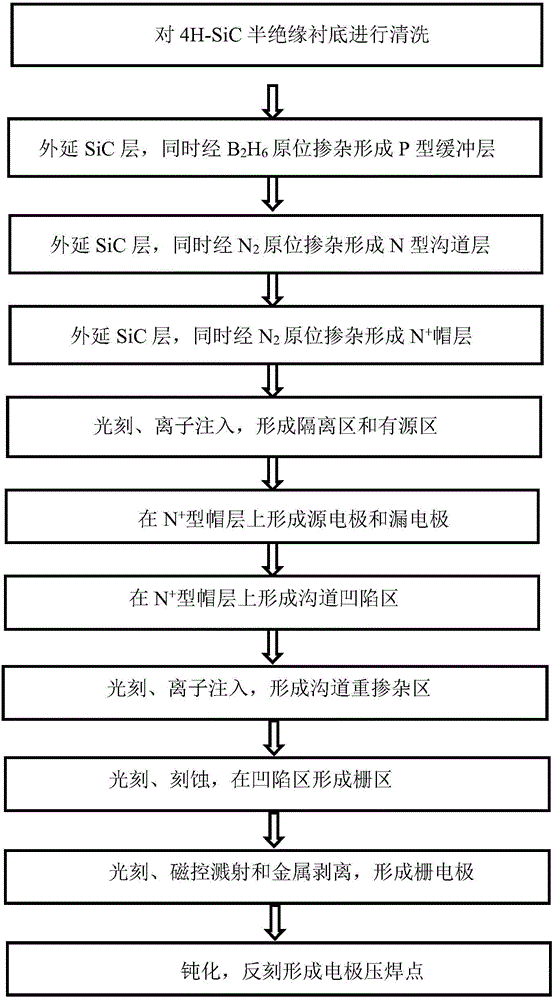

[0068] A method for preparing a 4H-SiC gold half field effect transistor with a partially highly doped channel, comprising the steps of:

[0069] Step 1) cleaning the 4H-SiC semi-insulating substrate (1) to remove dirt on the surface of the substrate;

[0070] Step 2) Epitaxially grow a 0.5 μm thick SiC layer on the 4H-SiC semi-insulating substrate (1), and at the same time, diborane B 2 h 6 In-situ doping, forming a concentration of 1.4×10 15 cm -3 P-type buffer layer (2);

[0071] Step 3) epitaxially grow a 0.4 μm-0.5 μm thick SiC layer on the P-type buffer layer (2), and at the same time 2 In-situ doping, forming a concentration of 3×10 17 cm -3 N-type channel layer (3);

[0072] Step 4) epitaxially grow a 0.2 μm thick SiC layer on the N-type channel layer (3), and at the same time 2 In-situ doping, forming a concentration of 2.0×10 19 cm -3 N + type cap layer;

[0073] Step 5) at N + Perform photolithography and isolation implantation sequentially on the type ...

Embodiment 1

[0121] The channel thickness is 0.3μm and has a part of N-type channel 9×10 17 cm -3 The preparation method of the 4H-SiC gold half field effect transistor in the heavily doped region is as follows:

[0122] Step 1) cleaning the 4H-SiC semi-insulating substrate 1 to remove dirt on the surface of the substrate;

[0123] a. Carefully clean the substrate two or three times with a cotton ball dipped in methanol to remove SiC particles of various sizes on the surface;

[0124] b. Place 4H-SiC semi-insulating substrate 1 in H 2 SO 4 :HNO 3 = Ultrasound for 5 minutes in 1:1;

[0125] c. Put the 4H-SiC semi-insulating substrate 1 in 1# cleaning solution (NaOH:H 2 o 2 :H 2 O=1:2:5) and boiled for 5 minutes, then rinsed with deionized water for 5 minutes and then put into 2# cleaning solution (HCl:H 2 o 2 :H 2 O=1:2:7) and boiled for 5 minutes, 2# cleaning solution is HCl:H 2 o 2 :H 2 O=1:2:7, finally rinsed with deionized water and washed with N 2 Blow dry and set aside....

Embodiment 2

[0170] Fabricate a channel region with a thickness of 0.35 μm and a part of N-type channel 9×10 18 cm -3 The preparation method of the 4H-SiC gold half-field-effect transistor in the heavily doped region is as follows: the difference between the production steps of this embodiment and the first embodiment is:

[0171] Step 3) epitaxially grow a 0.35 μm thick SiC layer on the P-type buffer layer 2, and at the same time 2 In-situ doping, forming a concentration of 3×10 17 cm -3 N-type channel layer 3;

[0172] The specific operation process is: put the 4H-SiC epitaxial wafer into the growth chamber, feed silane at a flow rate of 20ml / min, propane at 10ml / min and high-purity hydrogen at 80l / min into the growth chamber, and simultaneously feed 2ml / min N 2 , the growth temperature is 1550℃, the pressure is 10 5 Pa, last for 5min, complete doping concentration and thickness are 3×10 17 cm -3 and an N-type channel layer 3 of 0.35 μm.

[0173] Step 7) To the N between the sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com