Microbial pesticide and preparing method thereof

A microbial pesticide and weight fraction technology, applied in the field of pesticides, can solve the problems of low efficiency and low release rate of microbial pesticides, and achieve the effects of reducing water stress, facilitating degradation and inducing systemic resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

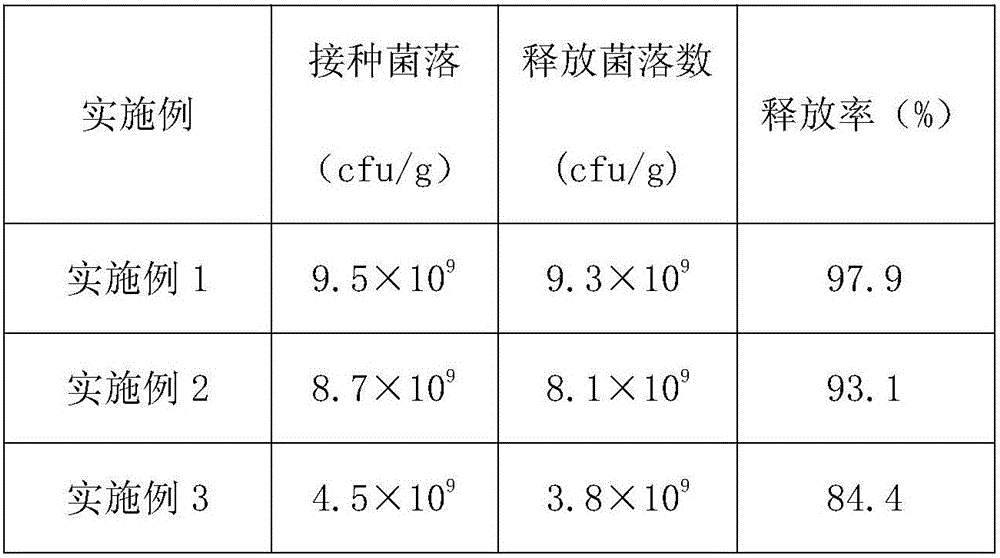

Examples

preparation example Construction

[0027] The present invention also provides a kind of preparation method of microbial pesticide, it is characterized in that, this method comprises: a, with vermiculite, diatomaceous earth, talcum powder, pseudo-boehmite, polyethylene glycol, urea and water with weight ratio 1: (3-10): (15-35): (0.1-0.6): (0.1-0.6): (1-5): (60-120) after mixing evenly, filter and dry to obtain the first solid; wherein , the vermiculite, diatomaceous earth, talcum powder, and pseudoboehmite are measured on a dry basis; b, the first solid obtained in step a is roasted at 350-430° C. for 1-10 hours to obtain the second Solid; c, pulverizing the second solid obtained in step c and passing through a 20-100 mesh sieve to obtain the first powder; d, sterilizing the first powder obtained in step c and mixing with Bacillus mycelia and sodium alginate , sodium carboxymethyl cellulose and chitin are uniformly mixed to obtain microbial pesticides; wherein, the weight fraction of sodium alginate in the micr...

Embodiment 1

[0037] Bacillus subtilis was inoculated in the culture medium according to the number of inoculated colonies of 1.5%, cultured at 20° C. for 5 days, the culture was taken out and filtered, and the obtained solid was regarded as Bacillus subtilis.

[0038] Vermiculite, diatomaceous earth, talcum powder, pseudoboehmite, polyethylene glycol, urea and water were mixed uniformly in a weight ratio of 1:3:15:0.1:0.1:1:60, filtered and dried to obtain the A solid; wherein, the vermiculite, diatomaceous earth, talcum powder, and pseudo-boehmite are measured on a dry basis; the first solid is roasted at 430° C. for 10 hours to obtain a second solid; the second solid obtained The solid is pulverized and passed through a 100-mesh sieve to obtain the first powder; the obtained first powder is sterilized and then mixed evenly with Bacillus mycelium, sodium alginate, sodium carboxymethylcellulose and chitin to obtain the microbial pesticide; wherein , the weight fraction of sodium alginate i...

Embodiment 2

[0040] The Bacillus licheniformis was inoculated in the culture medium according to the number of inoculated colonies of 0.3%, cultured at 25°C for 10 days, the culture was taken out and filtered, and the obtained solid was used as the mycelia of the Bacillus licheniformis.

[0041] Vermiculite, diatomaceous earth, talcum powder, pseudoboehmite, polyethylene glycol, urea and water are mixed uniformly at a weight ratio of 1:6:20:0.3:0.3:3:80, filtered and dried to obtain the A solid; wherein, the vermiculite, diatomaceous earth, talcum powder, and pseudo-boehmite are measured on a dry basis; the first solid is roasted at 350° C. for 5 hours to obtain a second solid; After the solid is pulverized and passed through a 20-mesh sieve, the first powder is obtained; after the obtained first powder is sterilized, it is evenly mixed with Bacillus mycelia, sodium alginate, sodium carboxymethylcellulose and chitin to obtain a microbial pesticide; wherein , the weight fraction of sodium a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com