Preparation method of porous adsorbent based on two cross-linking agents

A technology of porous adsorbent and cross-linking agent, which can be used in chemical instruments and methods, other chemical processes, etc., can solve problems such as complex properties, and achieve the effects of simple preparation, good repeatability and broad practical application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Preparation of reaction mixture reagent: the composition of the reaction monomer mixture is 30% of 1-vinyl-3-octylimidazolium tetrafluoroborate, 0.5% of initiator azobisisobutyronitrile, Crosslinking agent 69.5%, wherein divinylbenzene:N,N'-methylenebisacrylamide=1:0.25; the composition of the porogen is 70% of n-propanol, 1,4- Butanediol 30%; by mass ratio, reaction monomer mixture: porogen=1:0.5.

[0021] 2) Polymerization reaction: Weigh the reaction monomer, crosslinking agent, porogen and initiator according to the above ratio, and ultrasonically form a homogeneous solution. Then nitrogen gas was filled for 3 minutes, the above solution was poured into a container, sealed and placed in an oven at 60° C. for polymerization reaction at a constant temperature for 4 hours.

[0022] 3) Post-treatment of the adsorbent: put the adsorbent obtained in step 2) into a beaker, use acetonitrile as a solvent, and soak until no impurities are detected in the liquid.

Embodiment 2

[0024] 1) Preparation of reaction mixture reagent: the composition of the reaction monomer mixture is 35% of 1-vinyl-3-octylimidazolium tetrafluoroborate, 1% of initiator azobisisobutyronitrile, Crosslinking agent 64%, wherein divinylbenzene:N,N'-methylenebisacrylamide=1:0.5; the composition of the porogen is 60% of n-propanol, 1,4- Butanediol 40%; by mass ratio, reaction monomer mixture: porogen=1:0.81.

[0025] 2) Polymerization reaction: Weigh the reaction monomer and porogen according to the above ratio, mix them, and ultrasonically form a homogeneous solution, then fill with nitrogen for 5 minutes, pour the above solution into a container, seal it and place it in a 70°C oven for constant temperature polymerization reaction for 18 hours .

[0026] 3) Post-treatment of the adsorbent: the adsorbent obtained in step 2) is placed in a beaker, and methanol is used as a solvent, and soaked until no impurities are detected in the liquid.

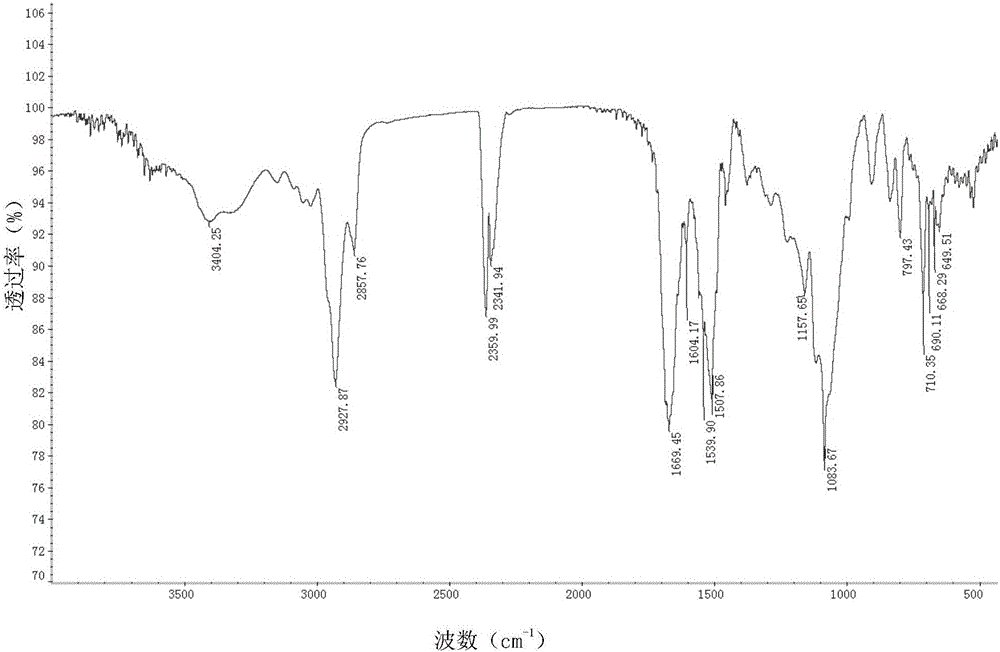

[0027] figure 1 is the infrared spect...

Embodiment 3

[0029] 1) Preparation of reaction mixture reagent: the composition of the reaction monomer mixture is 50% of 1-vinyl-3-octylimidazolium tetrafluoroborate by mass percentage, 2% of initiator benzoyl peroxide, and the remaining It is 48% of cross-linking agent, wherein divinylbenzene:N,N'-methylenebisacrylamide=1:1; the composition of said porogen is 80% of n-propanol by mass percentage, 1,4 - Butanediol 20%; by mass ratio, reaction monomer mixture: porogen = 1:1.

[0030] 2) Polymerization reaction: Weigh the reaction monomer and porogen according to the above ratio, mix them, and ultrasonically form a homogeneous solution, then fill with nitrogen for 20 minutes, pour the above solution into a container, seal it, and place it in a 75°C oven for constant temperature polymerization reaction for 24 hours .

[0031] 3) Post-treatment of the adsorbent: put the adsorbent obtained in step 2) into Soxhlet extraction, use ethanol as the solvent, and extract for 24 hours, or place the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com