Waterborne polyurethane, preparation method thereof, waterborne polyurethane automotive interior adhesive and preparation method thereof

A water-based polyurethane and automotive interior technology, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of poor water resistance and poor mechanical properties of water-based polyurethane, and achieve improved hydrolysis resistance and improved Effects of mechanical properties and excellent hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

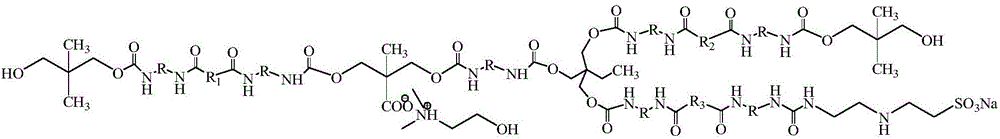

[0057] A kind of preparation method of aqueous polyurethane, comprises the following steps:

[0058] a) Under nitrogen protection, 180-320g poly(carbonate-ether) glycol, 42-130g polycaprolactone polyol and 23-65g polybutylene adipate polyol are at 110°C under reduced pressure After removing water for 2 hours, add 0.03-0.16g of catalyst and 75-196g of diisocyanate to react in 300-850mL of butanone, the reaction temperature is 75-85°C, and the reaction time is 2.5-6h to obtain the first intermediate;

[0059] The catalyst is dibutyltin dilaurate, stannous octoate or organic bismuth DabcoMB20 catalyst, and the diisocyanate is 1,6-hexamethylene diisocyanate, diphenylmethane diisocyanate, isophorone diisocyanate, 4,4-dicyclohexylmethane diisocyanate or 2,4-toluene diisocyanate.

[0060] b) Add 12.4-35.8g of dimethylolpropionic acid, 2.1-4.6g of trimethylolpropane and 110-200mL of butanone to the first intermediate for reaction, the reaction temperature is 80-90°C, and the reaction...

Embodiment 1

[0095] Embodiment 1, aqueous polyurethane resin synthesis

[0096] a) Under nitrogen protection, 180g poly(carbonate-ether) glycol (formula I) (m=10, n=10), 42g polycaprolactone polyol (formula II) ( p=8), 23g polybutylene adipate polyol (formula III) (q=8), 0.03g dibutyltin dilaurate and 75g diphenylmethane diisocyanate in 300mL methyl ethyl ketone, at reaction temperature is 75°C, and the reaction time is 6h to obtain the first intermediate;

[0097] b) Add 12.4g of dimethylolpropionic acid, 2.1g of trimethylolpropane and 110mL of butanone to the first intermediate at a temperature of 80°C and react for 5 hours to obtain the second intermediate;

[0098] c) Add 20 g of neopentyl glycol and 150 mL of butanone to the second intermediate at a temperature of 90° C. and react for 4 hours to obtain the third intermediate;

[0099] d) Add 6.5 g of dimethylethanolamine to the third intermediate at a temperature of 30° C. and react for 1 hour to obtain the fourth intermediate;

[...

Embodiment 2

[0102]Embodiment 2, aqueous polyurethane resin synthesis

[0103] a) Under nitrogen protection, 320g poly(carbonate-ether) glycol (formula I) (m=70, n=70), 130g polycaprolactone polyol (formula II) ( p=50), 65g polybutylene adipate polyol (formula III) (q=50), 0.16g stannous octoate and 196g of 4,4-dicyclohexylmethane diisocyanate in 850mL methyl ethyl ketone, The temperature is 85°C, the reaction time is 2.5h, and the first intermediate is obtained;

[0104] b) Add 35.8g of dimethylolpropionic acid, 4.6g of trimethylolpropane and 200mL of butanone to the first intermediate at a temperature of 90°C and react for 2 hours to obtain the second intermediate;

[0105] c) Add 36 g of neopentyl glycol and 220 mL of butanone to the second intermediate at a temperature of 100° C. and react for 2 hours to obtain the third intermediate;

[0106] d) Add 12.7 g of dimethylethanolamine to the third intermediate at a temperature of 45° C. and react for 0.5 h to obtain the fourth intermedia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com