Surface modification aramid fiber and preparation method thereof

A technology for modifying the surface of aramid fiber, applied in the field of organic fiber and its preparation, can solve the problems of organic solvent pollution of the environment, low comprehensive performance of composite materials, poor interface adhesion between aramid fiber and resin composite materials, etc., to achieve Effects of improving mechanical properties and thermal properties, reducing usage and emissions, and improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

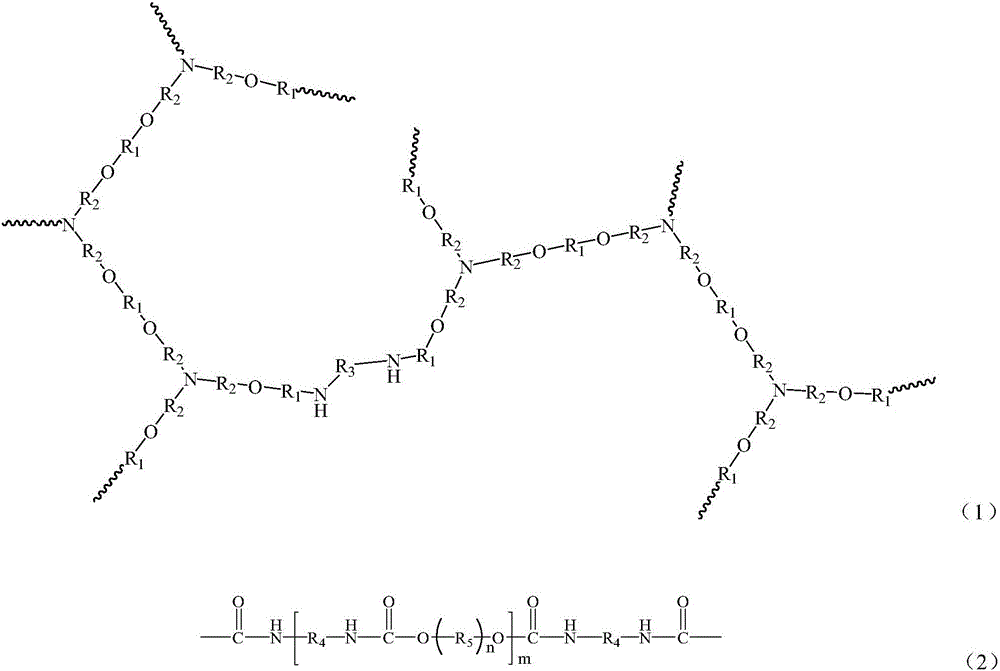

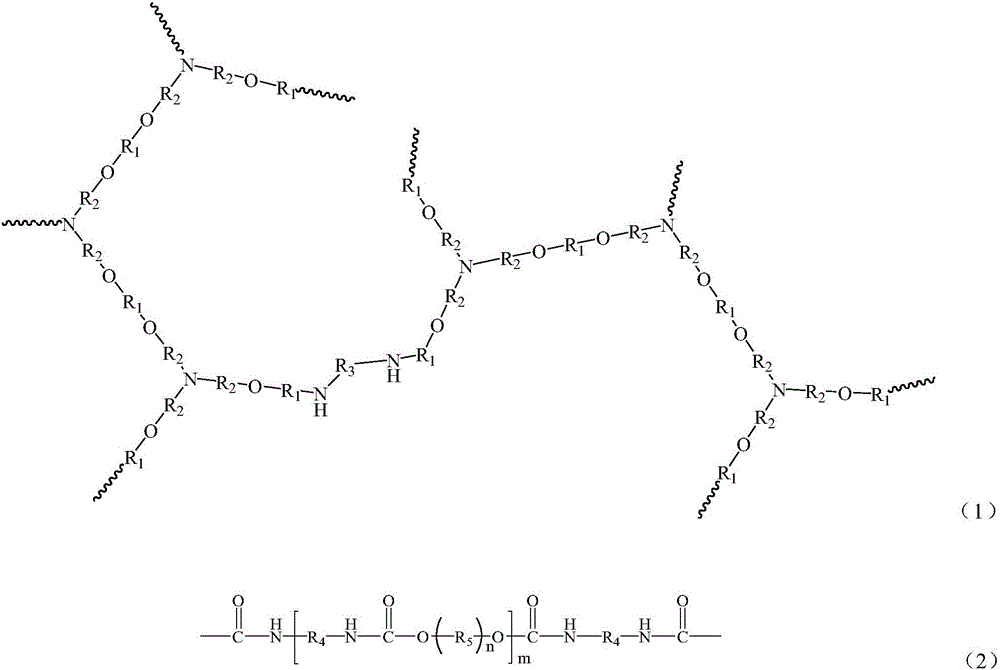

Method used

Image

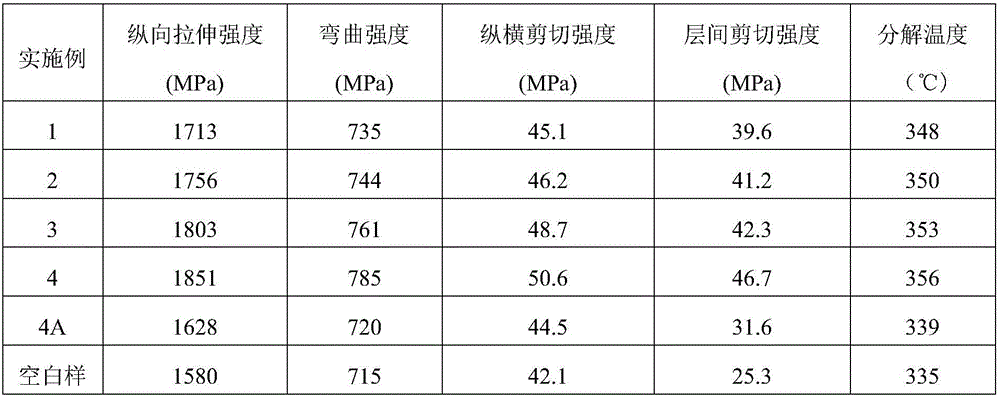

Examples

Embodiment 1

[0024] 1) Preparation of surface treatment agent: 100 parts of 3-(4-methylenecyclohexyl isocyanate) phenyl isocyanate and 0.5 part of stannous octoate are mixed and dissolved in ethylene carbonate to form a uniform solution with a mass fraction of 30% to obtain a surface treatment agent.

[0025] 2) Preparation of hyperbranched polyurethane: add 10 parts of trimethylhexamethylene diisocyanate, 10 parts of hexaethylene glycol and 0.05 part of stannous octoate into the reaction kettle, heat up to 80 ° C, and stir for 1 hour; add 1 1 part of tributanolamine, while adding 1 part of acetone, stirred for 5 hours; then added 1 part of concentrated hydrochloric acid, stirred for 30 minutes; slowly added the reaction solution to 80 parts of 1,3-propanediol with a mass fraction of 0.5% under high-speed stirring amine aqueous solution, and the temperature was raised to 70° C., and the reaction was stirred for 2 hours to obtain hyperbranched polyurethane.

[0026] 3) Aramid fiber surface...

Embodiment 2

[0029] 1) Preparation of surface treatment agent: 100 parts of 5-(ethyl isocyanate) naphthyl isocyanate and 1 part of di(dodecylthio)dibutyltin are mixed and dissolved in propylene carbonate to form a uniform solution with a mass fraction of 40%. Get a surface treatment.

[0030] 2) Preparation of hyperbranched polyurethane: Add 10 parts of dimethylene diisocyanate, 5 parts of triethylene glycol and 0.1 part of di(dodecylthio)dibutyltin into the reactor, heat up to 60°C, and stir for 2 Add 2 parts of triethanolamine and 2 parts of dimethyl carbonate, and stir for 3 hours; then add 1.5 parts of concentrated hydrochloric acid and stir for 10 minutes; slowly add the reaction solution to 100 parts of 0.15% 1, in an aqueous solution of 4-butanediamine, and the temperature was raised to 80° C., and the reaction was stirred for 1 hour to obtain hyperbranched polyurethane.

[0031] 3) Aramid fiber surface treatment: Pass the aramid fiber through the pressure roller of the oiling mach...

Embodiment 3

[0034] 1) Preparation of surface treatment agent: 100 parts of 4-(2-decenyl isocyanate) phenyl isocyanate and 2 parts of dibutyltin diacetate are mixed and dissolved in ethylene carbonate to form a uniform solution with a mass fraction of 50% to obtain surface treatment agent.

[0035]2) Preparation of hyperbranched polyurethane: add 10 parts of hexamethylene diisocyanate, 10 parts of heptagonal glycol and 0.1 part of dibutyltin diacetate into the reaction kettle, heat up to 65°C, and stir for 1.5 hours; add 1 part of Triisopropanolamine, while adding 3 parts of propylene carbonate, stirred and reacted for 5 hours; then added 1 part of glacial acetic acid, stirred for 50 minutes; slowly added the reaction solution to 90 parts of high-speed stirred aqueous solution with a mass fraction of 0.4% ethylenediamine , and heated up to 60°C, stirred and reacted for 3 hours to obtain hyperbranched polyurethane.

[0036] 3) Aramid surface treatment: Pass the aramid fiber continuously th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com