Method for preparing single-phase transparent conductive cuprous oxide film

A cuprous oxide, transparent and conductive technology, used in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of complex preparation process and harsh conditions, and achieve high deposition rate, good crystallinity, good The effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

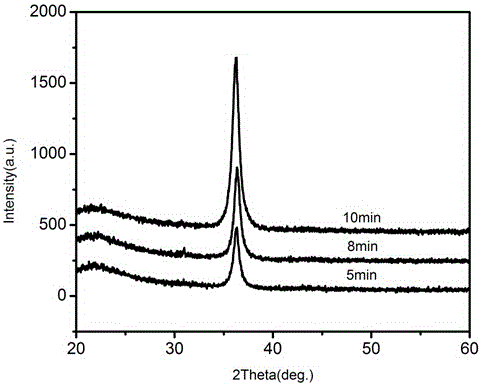

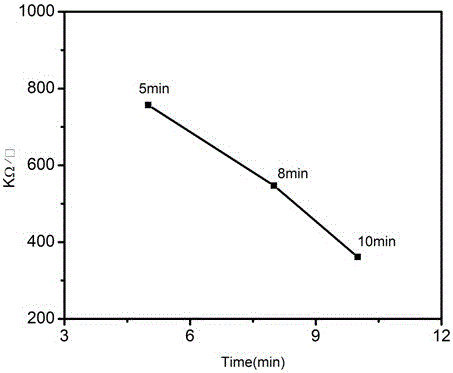

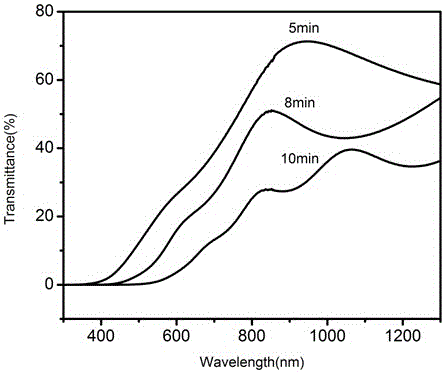

[0028] The DC reactive magnetron sputtering method was adopted at room temperature. A copper target is used as the sputtering target, high-purity oxygen is used as the reaction gas, and high-purity argon is used as the sputtering gas to deposit a cuprous oxide film on the substrate; wherein,

[0029] The copper target sputtering power is 40W, and the deposition time is 5min;

[0030] The oxygen flow rate is 5 sccm, and the argon flow rate is 5 sccm.

[0031] The specific operation steps are as follows:

[0032] 1. Use a dilute solution of an anionic surfactant (sodium fatty acid, etc., soapy water can be used) to pre-clean the substrate;

[0033] 2. Use acetone, alcohol and deionized water to ultrasonically clean the substrate for 10 minutes in sequence, and control the temperature at 0°C;

[0034] 3. The metal copper with a purity of 99.99% is used as the cathode target, the anode is connected to the vacuum chamber, the quartz substrate after ultrasonic cleaning is install...

Embodiment 2

[0039] The DC reactive magnetron sputtering method was adopted at room temperature. A copper target is used as the sputtering target, high-purity oxygen is used as the reaction gas, and high-purity argon is used as the sputtering gas to deposit a cuprous oxide film on the substrate; wherein,

[0040] The copper target sputtering power is 80W, and the deposition time is 8min;

[0041] The oxygen flow rate is 15 sccm, and the argon flow rate is 50 sccm.

[0042] The specific operation steps are as follows:

[0043] 1. Use a diluted solution of anionic surfactant (sodium fatty acid, etc., soapy water can be used) to pre-clean the substrate, and then use acetone, alcohol and deionized water to perform ultrasonic cleaning on the substrate for 10 minutes, and the temperature is controlled at 0 ℃;

[0044] 2. The metal copper with a purity of 99.99% is used as the cathode target, the anode is connected to the vacuum chamber, the quartz substrate after ultrasonic cleaning is instal...

Embodiment 3

[0049] The DC reactive magnetron sputtering method was adopted at room temperature. A copper target is used as the sputtering target, high-purity oxygen is used as the reaction gas, and high-purity argon is used as the sputtering gas to deposit a cuprous oxide film on the substrate; wherein,

[0050] The copper target sputtering power is 150W, and the deposition time is 10min;

[0051] The oxygen flow rate is 30 sccm, and the argon flow rate is 100 sccm.

[0052] The specific operation steps are as follows:

[0053] 1. Use a diluted solution of anionic surfactant (sodium fatty acid, etc., soapy water can be used) to pre-clean the substrate, and then use acetone, alcohol and deionized water to perform ultrasonic cleaning on the substrate for 10 minutes, and the temperature is controlled at 0 ℃;

[0054] 2. The metal copper with a purity of 99.99% is used as the cathode target, the anode is connected to the vacuum chamber, the quartz substrate after ultrasonic cleaning is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com