Reduced graphene/ferroferric oxide/precious metal nanocomposite and preparation method and application thereof

A nanocomposite material, ferric oxide technology, applied in the field of materialization, can solve the problems of difficult filtration or separation and recovery, small particle size, etc., and achieve the effect of surface enhanced Raman activity, high adsorption characteristics, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of magnetic Fe3O4 nanoparticles by ferric chloride

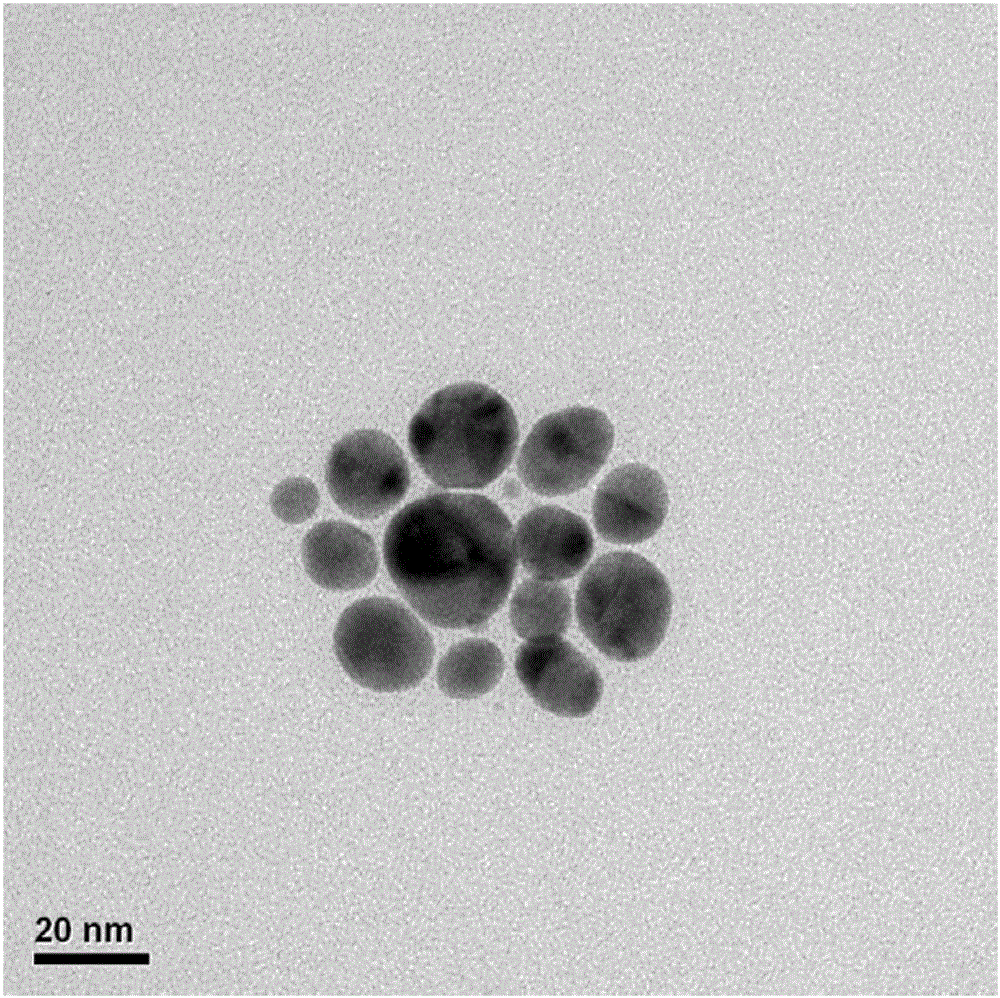

[0041]Dissolve 0.5g of ferric chloride hexahydrate and 1.2g of hexamethylenetetramine in 100mL of ethylene glycol solution, ultrasonically disperse for 45min, then move to a hydrothermal autoclave, react at 200°C for 10h, after the reaction is complete Cool to room temperature, use a magnet to separate the magnetic substance from the solution, wash it repeatedly with deionized water and absolute ethanol and then separate it with a magnet, and then dry the separated magnetic iron ferric oxide nanoparticles at 100 °C for 12 hours, Ultrasonic disperse in 10mL deionized water, and finally obtain the magnetic ferric oxide nanomaterial ( figure 1 ).

[0042] (2) Prepare reduced graphene solution using cysteine

[0043] Under the condition of ice-water bath, add 0.5g of graphite powder, 0.5g of sodium nitrate and 20mL of concentrated sulfuric acid with a mass fraction of 98% in the three-necked flask succes...

Embodiment 2

[0051] (1) Preparation of magnetic Fe3O4 nanoparticles by ferric nitrate

[0052] Dissolve 1.2g of ferric nitrate nonahydrate and 2.5g of hexamethylenetetramine in 200mL of ethylene glycol solution, and after ultrasonic dispersion for 60min, move it to a hydrothermal autoclave, react at 250°C for 6h, cool down after the reaction is complete to room temperature, use a magnet to separate the magnetic substance from the solution, wash it repeatedly with deionized water and absolute ethanol, and then separate it with a magnet, then dry the separated magnetic ferric iron tetroxide nanoparticles at 100°C for 12 hours, and ultrasonically Disperse in 10mL of deionized water to finally obtain the magnetic Fe3O4 nanometer material, the concentration of the magnetic Fe3O4 is about 68 mg / mL.

[0053] (2) Prepare reduced graphene solution using bovine serum albumin

[0054] Under the condition of ice-water bath, add 1.0g of graphite powder, 1.5g of sodium nitrate and 30mL of concentrated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com