Method for preparing microbial fuel cell electrode material employing rape stalks

A fuel cell electrode, rape straw technology, applied in biochemical fuel cells, battery electrodes, circuits, etc., achieves the effects of fast electron migration rate, good biocompatibility, and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Shred the rape stalks and dry them with H 2 SO 4 Mix the solution in a hydrothermal kettle, select the concentration of 10%, 30%, 50%, react at 150°C for 3 hours, filter it to neutral after cooling, add distilled water and product 1:1.5 to mix, continue to add water In a hot kettle, react at 150°C for 3 hours and then dry to obtain hydrothermal carbon. The sample was carbonized in a tube furnace under nitrogen atmosphere, the carbonization temperature was 400°C, the heating rate was 10°C / min, and the nitrogen flow rate was controlled at 0.6L / min. Soak in % HF for 6 hours, wash until neutral and dry; mix the sample with KOH and activate it under a nitrogen atmosphere in a tube furnace. / min, the reaction time is 1h, 1.5h, 2h, the activation ratio is 1:2, 1:3, 1:4, 1:5, 1:6, soak in 5wt% HCl for 6h after activation, and wash until neutral And mark after drying.

[0045] The mark format is Y (rape stalk)-30 (hydrothermal reaction sulfuric acid concentration)-800 (activ...

Embodiment 2

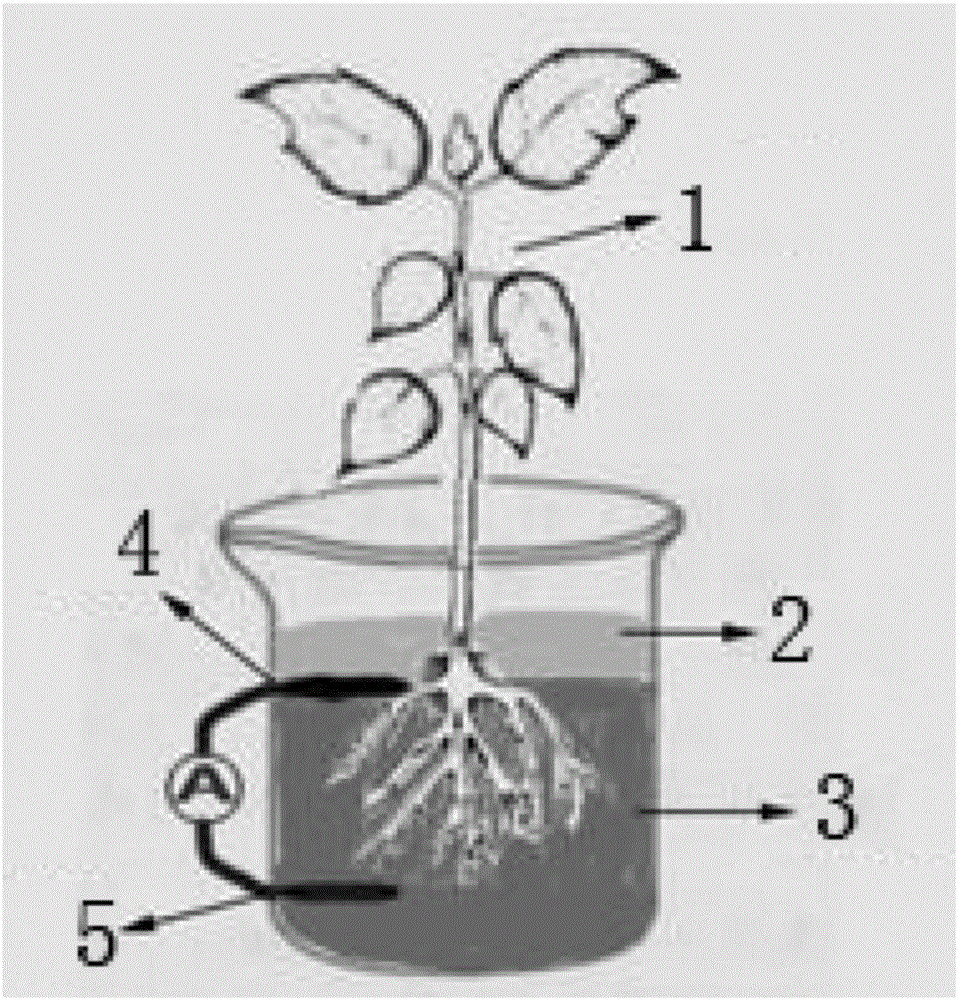

[0054] The electrode obtained in Example 1 is carried in the microbial fuel cell system, such as figure 1 As shown, the microbial fuel cell includes a plant 1, a natural water body 2 and a sludge 3, and two electric stages of an anode 5 and a cathode 4 are installed in the natural water body 2 and the sludge 3. Use a multimeter to measure the power production of the battery, take the value 3 times a day, and record the data for a week continuously. The data taken are the current and voltage of the battery. The data is recorded at 9:00 am, 13:00 noon, and 17:00 pm every day. The statistical time is one week, with a total of 21 numbers. See Table 2 for details.

[0055] Table 2 Power production data of microbial fuel cell system

[0056] Numbering

[0057] It can be seen from Table 2 that the power generation capacity of the battery system increases steadily, the highest current reaches 0.390mA, and the voltage reaches 176.1mV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com