Method for extracting highly active lignin from biomass and lignin obtained therefrom

A lignin and high-activity technology, applied in the direction of lignin derivatives, chemical instruments and methods, organic chemistry, etc., can solve the problems of expensive treatment costs, severe pretreatment conditions, and undetectability, and achieve recovery and recycling , Improve evaporation efficiency, promote the effect of enzymatic hydrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

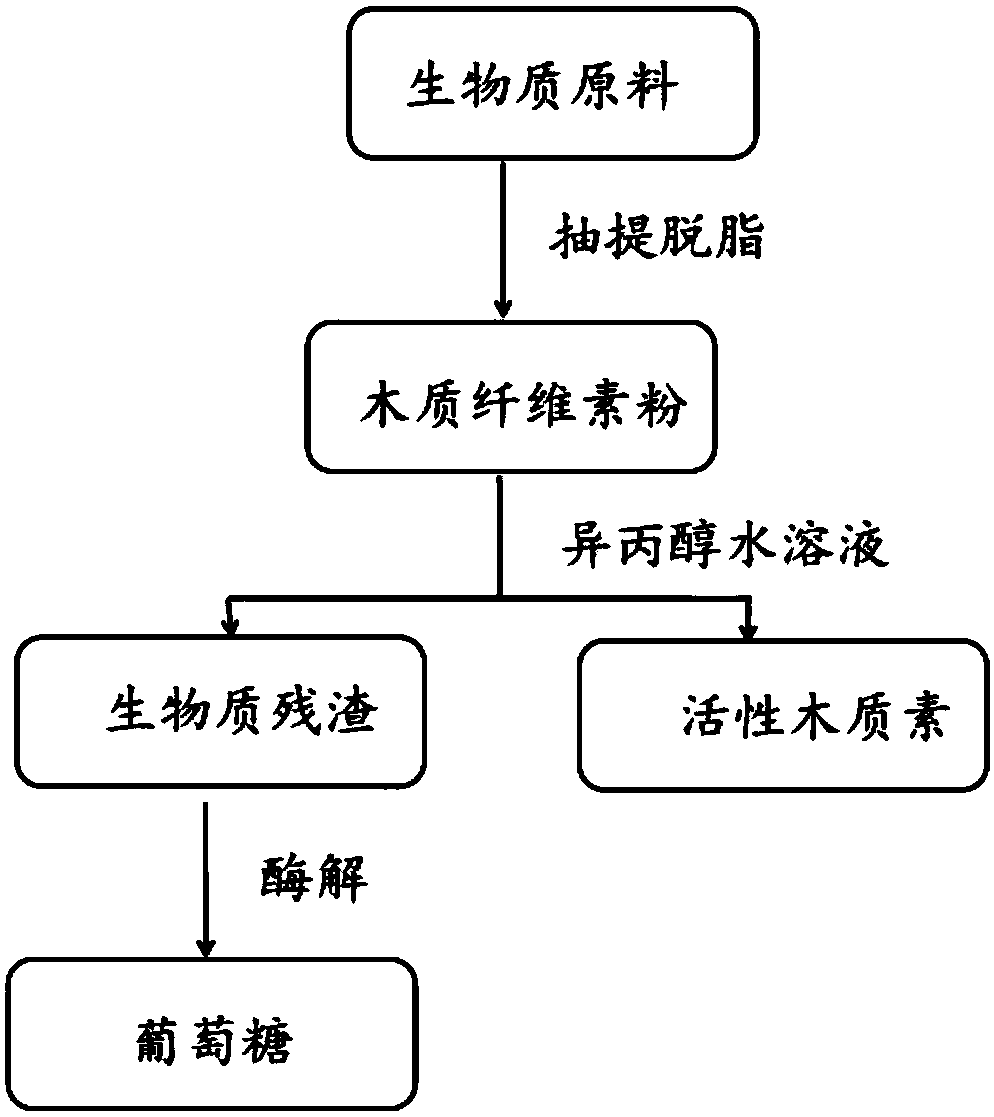

[0049] Such as figure 1 Shown, a kind of method for extracting highly active lignin from biomass, comprises the following steps:

[0050] (1) Biomass raw material pretreatment stage: crush eucalyptus wood and pass through a 40-mesh sieve, mix toluene and ethanol at a volume ratio of 2:1 to obtain a benzyl alcohol solution, and put eucalyptus wood powder in a Soxhlet extractor for use Benzyl alcohol solution was extracted for 6 hours, and then dried at 80°C to obtain lignocellulose powder;

[0051] (2) Extraction stage of lignin: place the lignocellulose powder obtained in step (1) and 70% isopropanol aqueous solution according to the solid-liquid ratio of 1:10 (m / v) in a 200° C. Extract in the autoclave for 60 minutes, after the extraction, pass condensed water into the autoclave to make it drop to room temperature, and filter with a 200-mesh filter cloth to separate the solid-liquid mixture in the autoclave to obtain biomass residue and filtrate;

[0052] (3) Separation sta...

Embodiment 2

[0055] Such as figure 1 Shown, a kind of method for extracting highly active lignin from biomass, comprises the following steps:

[0056] (1) Biomass raw material pretreatment stage: crush eucalyptus wood and pass through a 40-mesh sieve, mix toluene and ethanol at a volume ratio of 2:1 to obtain a benzyl alcohol solution, and put eucalyptus wood powder in a Soxhlet extractor for use Benzyl alcohol solution was extracted for 8 hours, and then dried at 70°C to obtain lignocellulose powder;

[0057] (2) Extraction stage of lignin: place the lignocellulose powder obtained in step (1) and 70% isopropanol aqueous solution according to the solid-liquid ratio of 1:10 (m / v) in a 220° C. Extract in the autoclave for 60min, after the extraction, pass condensed water into the autoclave to make it drop to room temperature, and filter with a 300-mesh filter cloth to separate the solid-liquid mixture in the autoclave to obtain biomass residue and filtrate;

[0058] (3) Separation stage of...

Embodiment 3

[0061] Such as figure 1 Shown, a kind of method for extracting highly active lignin from biomass, comprises the following steps:

[0062] (1) Biomass raw material pretreatment stage: crush eucalyptus wood and pass through a 50-mesh sieve, mix toluene and ethanol at a volume ratio of 2:1 to obtain a benzyl alcohol solution, and put eucalyptus wood powder in a Soxhlet extractor for use Benzyl alcohol solution was extracted for 7 hours, and then dried at 80°C to obtain lignocellulose powder;

[0063] (2) Extraction stage of lignin: place the lignocellulose powder obtained in step (1) and 70% isopropanol aqueous solution according to the solid-liquid ratio of 1:10 (m / v) in a 200° C. Extract in the autoclave for 120min, after the extraction, pass condensed water into the autoclave to make it drop to room temperature, and filter with a 200-mesh filter cloth to separate the solid-liquid mixture in the autoclave to obtain biomass residue and filtrate;

[0064] (3) Separation stage o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com