Surface plasmon switch and manufacturing method thereof

A surface plasmon and switch technology, applied in the field of nanophotonics, can solve the problems of limited surface plasmon resonance control, poor surface plasmon resonance performance, polyaniline film contact, etc., to achieve good control Capability and environmental stability, excellent performance, effect of strong extinction cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The outstanding advantages of the preparation method of the composite nanomaterial are: the synthesis method is simple, the production efficiency is high, the core-shell nanostructure is constructed conveniently and accurately, there is no harmful solvent, and large-scale production can be carried out in practice.

[0041] In other embodiments, the method of changing the redox degree of polyaniline or changing the proton doping degree to realize the function of switching surface plasmons includes the following two methods:

[0042] (1) Introducing electrochemical means to change the redox degree of polyaniline

[0043] By controlling the concentration of the nanoparticle solution and the contact time between the solution and the substrate, the gold-polyaniline composite nanoparticle with core-shell structure can be dispersed on the surface of the electrode, which serves as the working electrode of the electrochemical reaction cell. Under different potentials, the gold-p...

Embodiment 1

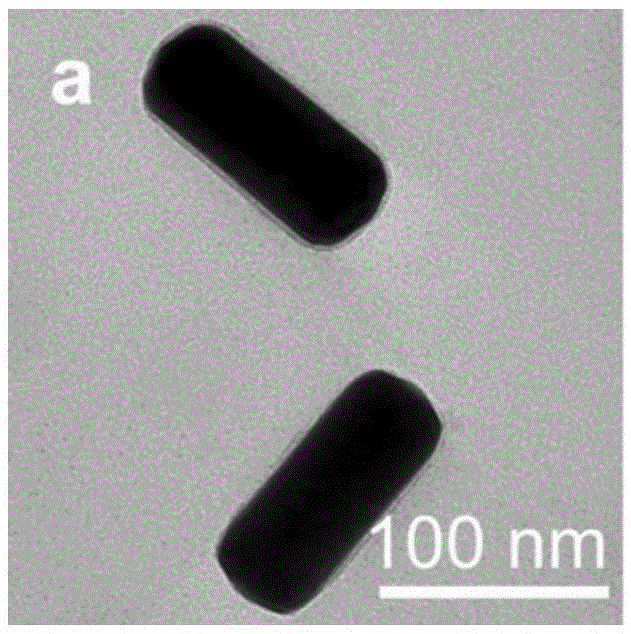

[0051] 1. Preparation of polyaniline-coated gold nanorods

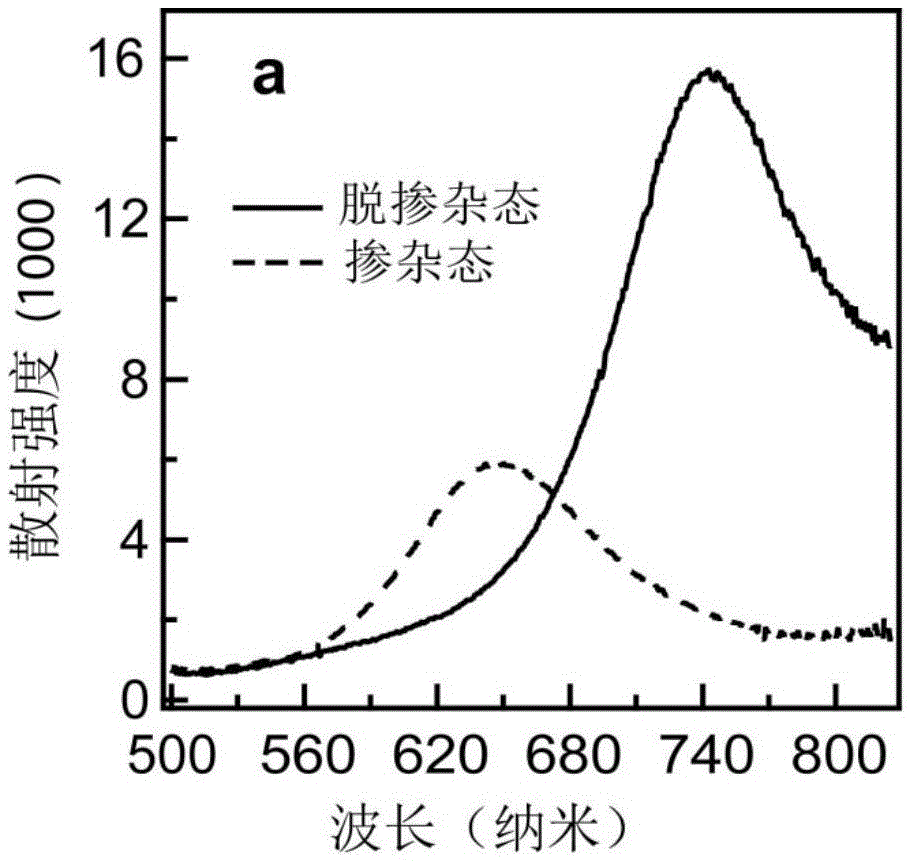

[0052] Dissolve 0.26mg of aniline monomer in 1.8mL, 7mmol / L sodium lauryl sulfate aqueous solution, stir at room temperature for 7 minutes, and gold nanorods (average length is 52 ± 3nm, average diameter is 111 ± 6nm) Add and disperse in the above-mentioned solution of step, the molar concentration ratio of gold nanorod and aniline monomer in this solution is 9.3×10 14 After mixing and shaking for 15 minutes, 0.75 mg of potassium persulfate was dissolved in 1.5 mL of hydrochloric acid and mixed with the above solution for 7 minutes and then reacted at room temperature for 8 hours to obtain a gold nanorod composite material coated with polyaniline. The microstructure of the composite material is as Figure 1a As shown, it can be clearly seen that polyaniline forms a uniform shell structure on the surface of gold nanorods, and the thickness of the shell is about 4 nm. After the polyaniline-coated gold nanorods go throu...

Embodiment 2

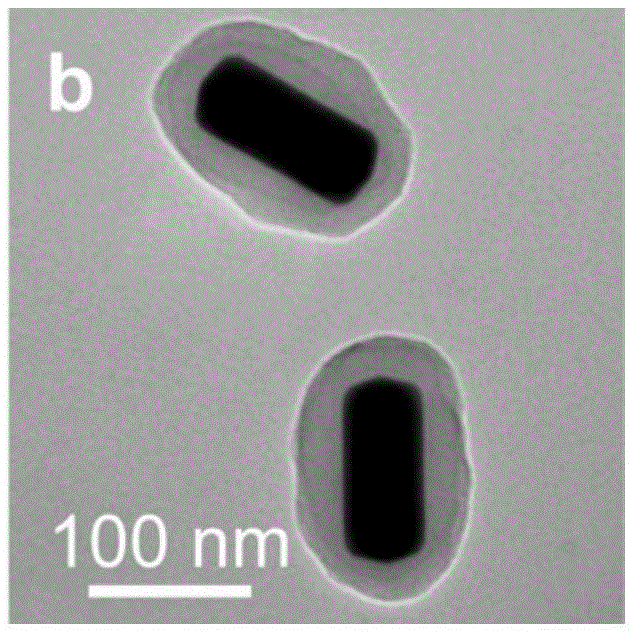

[0057] 1. Preparation of polyaniline-coated gold nanospheres

[0058] The steps are the same as the preparation steps of polyaniline-coated gold nanorods in Example 1, gold nanospheres (average diameter is 84 ± 5nm) instead of gold nanorods (average length is 52 ± 3nm, and average diameter is 111 ± 6nm), The molar concentration ratio of gold nanospheres and aniline monomer in this solution is 1.1×10 14 , the dosage of potassium persulfate was changed to 1.5 mg. The microstructure of the prepared polyaniline-coated gold nanospheres is as follows: Figure 3a-Figure 3b As shown, it can be clearly seen from the figure that the polyaniline forms a uniform shell structure on the surface of the gold nanosphere, and the thickness of the shell is about 22nm.

[0059] 2. Introduce a microfluidic device that changes the degree of proton doping

[0060] The steps of placing the polyaniline-coated gold nanospheres into the polydimethylsiloxane microfluidic chip in Example 1 are the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com