Sterilizing detergent high in infiltrating capacity and preparation method thereof

A technology of cleaning agent and ability, applied in the field of cleaning agent, can solve the problems of waste, environmental hazards, pollution, etc., and achieve the effects of less industrial emission of pollutants, improved use efficiency, and concise preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

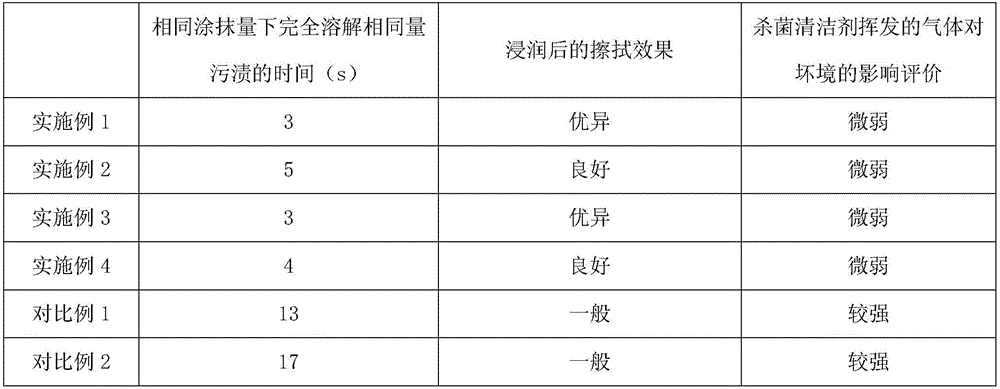

Examples

Embodiment 1

[0019] (1) Weigh 35 parts of polyethylene glycol octyl phenyl ether, 30 parts of chloromethoxy fatty acid methyl ester, 25 parts of sodium dodecylbenzenesulfonate, 25 parts of cocamidopropyl dimethylamine, 20 parts of polyvinylpyrrolidone, 20 parts of N-fatty acylglutamic acid ethanolamine salt, 15 parts of lignosulfonate, 15 parts of ginkgo biloba extract, 10 parts of alkyl imidazoline quaternary ammonium salt, 10 parts of triethanolamine, iso 5 parts of propanol, 2 parts of sodium carbonate, 75 parts of water, 10 parts of diethylene glycol monobutyl ether;

[0020] (2) Add polyethylene glycol octylphenyl ether, chloromethoxy fatty acid methyl ester, sodium dodecylbenzenesulfonate, cocamidopropyl dimethylamine, polyvinylpyrrolidone, and water into the reaction kettle Stir evenly at a speed of 320 rpm to obtain a preliminary mixture;

[0021] (3) After the preliminary mixing is heated to 85° C., N-fatty acyl glutamic acid ethanolamine salt, lignin sulfonate, ginkgo biloba ext...

Embodiment 2

[0025] (1) Weigh 37 parts of polyethylene glycol octyl phenyl ether, 32 parts of chloromethoxy fatty acid methyl ester, 27 parts of sodium dodecylbenzenesulfonate, 27 parts of cocamidopropyl dimethylamine, 22 parts of polyvinylpyrrolidone, 22 parts of N-fatty acyl glutamate ethanolamine salt, 17 parts of lignosulfonate, 17 parts of ginkgo biloba extract, 12 parts of alkyl imidazoline quaternary ammonium salt, 12 parts of triethanolamine, isopropyl 7 parts of alcohol, 3 parts of potassium carbonate, 80 parts of water;

[0026] (2) Add polyethylene glycol octylphenyl ether, chloromethoxy fatty acid methyl ester, sodium dodecylbenzenesulfonate, cocamidopropyl dimethylamine, polyvinylpyrrolidone, and water into the reaction kettle Stir evenly at a speed of 320 rpm to obtain a preliminary mixture;

[0027] (3) After the preliminary mixing is heated to 87° C., N-fatty acyl glutamic acid ethanolamine salt, lignin sulfonate, ginkgo biloba extract, and alkylimidazoline quaternary ammo...

Embodiment 3

[0031] (1) Weigh 40 parts of polyethylene glycol octyl phenyl ether, 35 parts of chloromethoxy fatty acid methyl ester, 30 parts of sodium dodecylbenzenesulfonate, 30 parts of cocamidopropyl dimethylamine, 25 parts of polyvinylpyrrolidone, 25 parts of N-fatty acyl glutamic acid ethanolamine salt, 20 parts of lignosulfonate, 20 parts of ginkgo biloba extract, 15 parts of alkyl imidazoline quaternary ammonium salt, 15 parts of triethanolamine, isopropyl 10 parts of alcohol, 5 parts of sodium bicarbonate, 90 parts of water, 15 parts of 3-hydroxypiperidine hydrochloride;

[0032] (2) Add polyethylene glycol octylphenyl ether, chloromethoxy fatty acid methyl ester, sodium dodecylbenzenesulfonate, cocamidopropyl dimethylamine, polyvinylpyrrolidone, and water into the reaction kettle Stir evenly at a speed of 320 rpm to obtain a preliminary mixture;

[0033] (3) After the preliminary mixing is heated to 90° C., N-fatty acyl glutamic acid ethanolamine salt, lignin sulfonate, ginkgo b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com