Pendimethalin micro-capsule suspending agent and preparation method thereof

A technology of pendimethalin and microcapsule suspension, applied in botany equipment and methods, biocides, biocides, etc., can solve problems such as polluting equipment, affecting users, and easy coloring of liquid preparations, and achieves low cost Inexpensive, prevents aggregation of microcapsules, and improves long-term storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、10

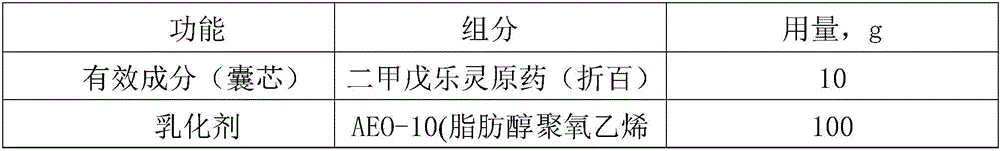

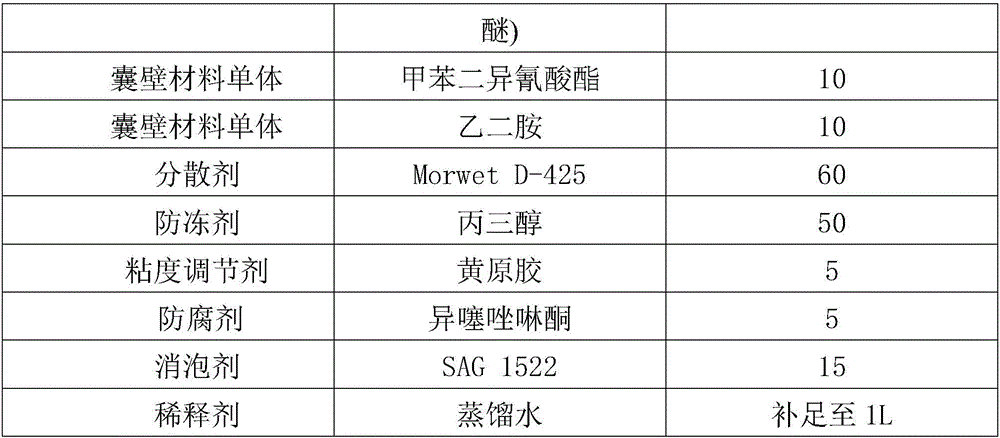

[0079] Embodiment 1, 10g / L pendimethalin microcapsule suspension

[0080] According to the dosage in Table 1, heat pendimethalin (active ingredient 10g) to a molten state, add 10g toluene diisocyanate (vesicle wall material monomer), stir well and then add 100g AEO-10 (emulsifier) , mix the three evenly to prepare an oil phase;

[0081] Add 10g of ethylenediamine (vesicle wall material monomer), 50g of glycerol (antifreeze), 30g of Morwet D-425 (dispersant) and 15g of SAG 1522 (defoamer) in distilled water in sequence, and stir evenly to prepare water Mutually;

[0082] The oil phase and the water phase were respectively kept warm under a constant temperature water bath at 60°C to prevent the pendimethalin original drug from being precipitated when cold, and after the oil phase and the water phase were mixed, shear emulsification at 10000rpm for 1.5min (D 50 controlled at 5 μm to 7 μm), to prepare an oil-in-water emulsion;

[0083] Heat the prepared oil-in-water emulsion ...

Embodiment 2

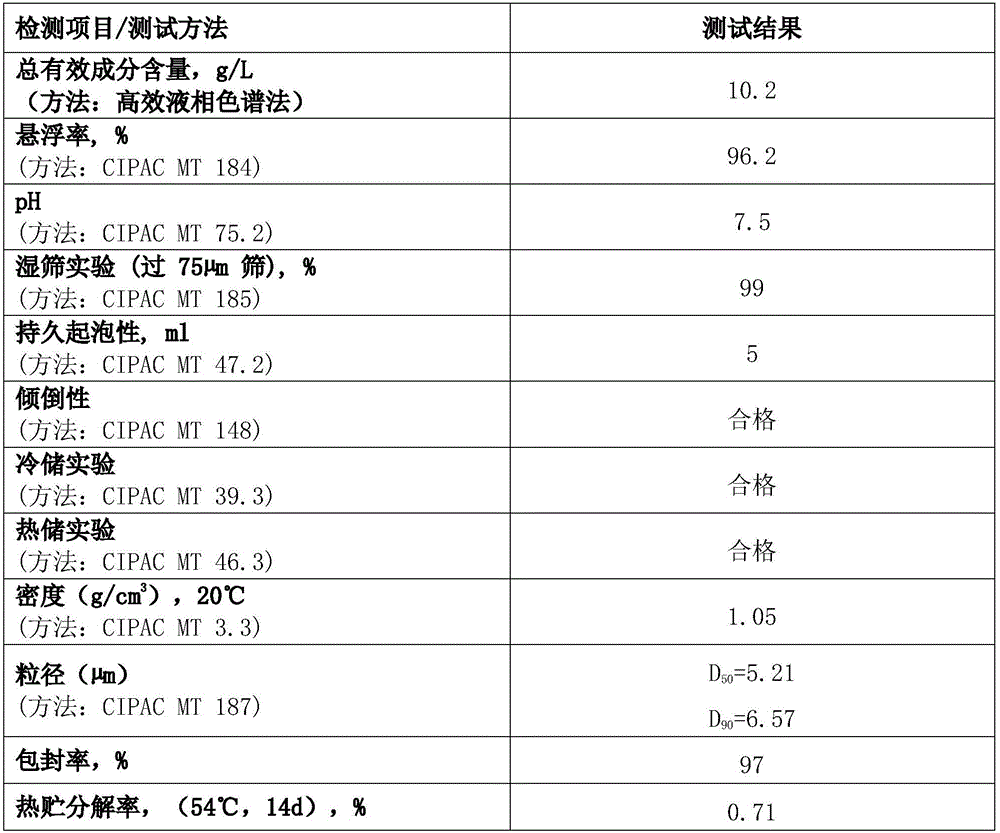

[0093] Embodiment 2.50g / L pendimethalin microcapsule suspension

[0094] According to the dosage in Table 3, the former drug of pendimethalin (50 g of active ingredient) was heated to a molten state, 90 g of diphenylmethane diisocyanate (vesicle wall material monomer) was added, and 20 g of OP-10 was added after stirring evenly. Mix the three evenly to prepare an oil phase;

[0095] Add 10g of pentaerythritol (capsule wall material monomer), 50g of urea (antifreeze), 20g of Emulsogen 3510 (dispersant) and 10g of polyether defoamer (defoamer) in deionized water in sequence, and stir evenly to prepare an aqueous phase;

[0096] The oil phase and the water phase were kept warm in a constant temperature water bath at 60°C, and after mixing the oil phase and the water phase, shear emulsified at 5000rpm for 2.5min (D 50 controlled at 4 μm to 7 μm), to prepare an oil-in-water emulsion;

[0097] Insulate the prepared oil-in-water emulsion in a water bath at 60°C, and react for 2 hou...

Embodiment 3

[0105] Embodiment 3.100g / L pendimethalin microcapsule suspension

[0106] According to the dosage in Table 5, heat pendimethalin (active ingredient 100g) to molten state, add 30g diphenylmethane diisocyanate (capsule wall material monomer), stir well and then add 50g AEO-9 ( emulsifier), the three are mixed evenly to prepare an oil phase;

[0107] Add 30g diethylaminopropylamine (capsule wall material monomer), 80g glycerol (antifreeze), 25g Dispersogen LFS (dispersant) and 8g organosilicon defoamer (defoamer) successively in deionized water, stir Uniformly prepared into an aqueous phase;

[0108] The oil phase and the water phase were kept warm in a constant temperature water bath at 60°C, and after mixing the oil phase and the water phase, they were sheared and emulsified at 8000rpm for 2min (D 50 controlled at 5 μm to 7 μm), to prepare an oil-in-water emulsion;

[0109] Insulate the prepared oil-in-water emulsion in a water bath at 60°C, and react for 2 hours under the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com