A 3D printed porous scaffold with antibacterial functional coating and its preparation method

A porous stent, 3D printing technology, applied in the direction of coating, prosthesis, tissue regeneration, etc., can solve the problems of cumbersome and limited sterilization effect of metal ions, and achieve the effect of simplifying the preparation steps, improving long-term stability and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

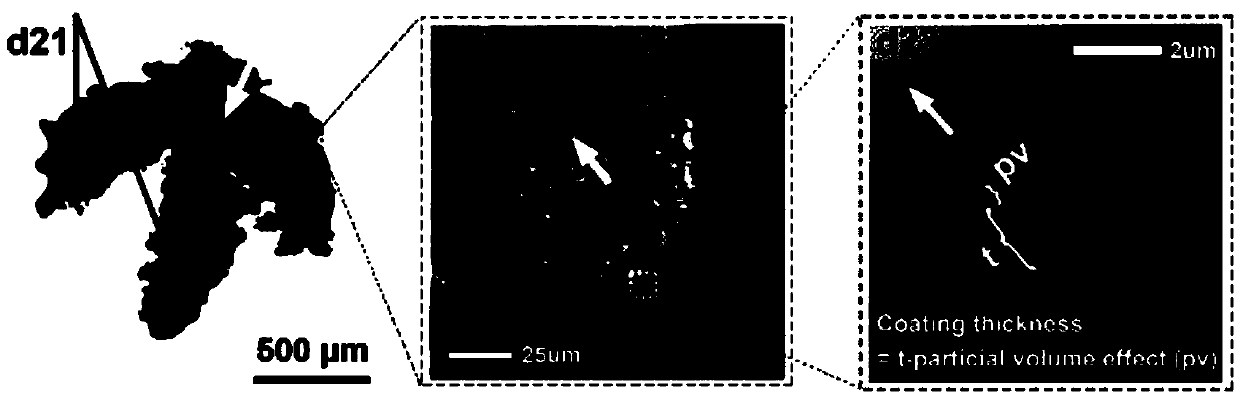

[0036] The embodiment of the present invention also provides a method for preparing a 3D printed porous scaffold with an antibacterial functional coating, the method mainly includes the following steps:

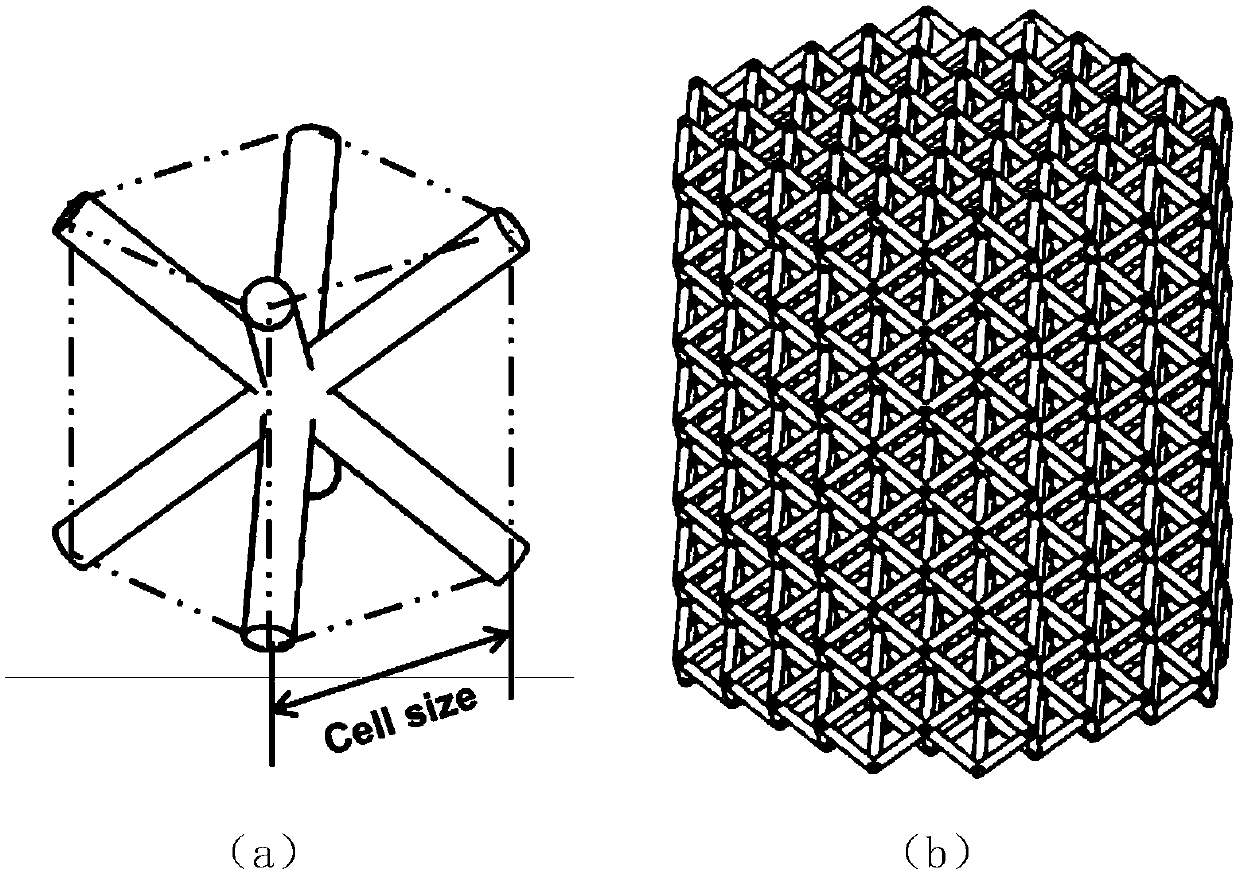

[0037] 1) Establish a three-dimensional model of the porous scaffold through computer modeling software, and then import it into the SLM device for slicing;

[0038] 2) Prepare the metal powder and determine the optimized process parameters to form the porous scaffold:

[0039] Specifically select the following process parameters: laser power 180W-300W, laser spot diameter 0.05mm-0.1mm, scanning distance 50μm-70μm, scanning speed 200mm / s-400mm / s, powder layer thickness 20μm-30μm, using the above process parameters, It can form Co-Cr alloy entities with better surface quality.

[0040] 3) Prepare silk fibroin / gentamycin mixed solution:

[0041] First, add silkworm cocoons to 0.02M sodium carbonate solution, boil for 20 minutes, and then rinse with ultrapure water; secondly, ...

Embodiment 1

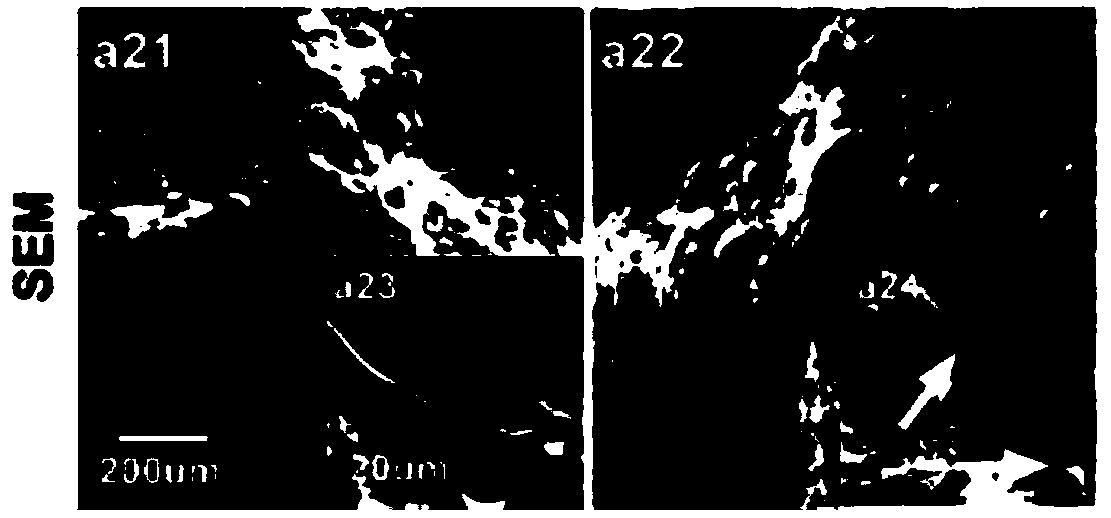

[0048] The three-dimensional model of the porous scaffold is established by computer modeling software. The model is a cylindrical porous scaffold with an outer diameter of 8 mm and a height of 10 mm. The porous scaffold is formed by stacking body-centered cubic units. The size of the topological unit is 1250 μm, and the diameter of the pillar is 200 μm. Then import the model into SLM equipment for slicing processing; use Co-Cr alloy powder, set the process parameters as laser power 220W, scanning distance 70μm, scanning speed 300mm / s, powder layer thickness 20μm, and form Co-Cr porous scaffold.

Embodiment 2

[0050] Add silkworm cocoons to 0.02M sodium carbonate solution, boil for 20 minutes, and then rinse with ultrapure water; secondly, after drying the extracted silk fibroin, add 9.3M lithium bromide solution to dissolve in 60°C water bath for 4 hours; The obtained solution was poured into a dialysis belt, and dialyzed in ultrapure water at 4°C for 72 hours; finally, the solution was centrifuged at 1500rpm at 4°C for 40 minutes to remove the insoluble part, and finally diluted to a concentration of 20mg / mL silk fibroin solution. Gentamicin was prepared into a solution with a concentration of 1 mg / mL, and added to the silk fibroin solution to prepare a silk fibroin / gentamicin mixed solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com