Nanocage metal high-temperature anticorrosion thermal insulation material

A technology of thermal insulation materials and nano-cages, applied in the field of thermal insulation and energy-saving materials, can solve the problems of consuming manpower and material resources, low-end thermal insulation effects, etc., and achieve the effects of saving energy waste, reducing heat consumption, and excellent combustion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A nano-cage metal high-temperature anti-corrosion and thermal insulation material, which is made of the following raw materials in parts by weight: 5 parts of ceramic fiber, 20 parts of glass microspheres, 5 parts of montmorillonite powder, 10 parts of serpentine asbestos, and anionic polypropylene 1 part of amide, 0.01 part of sodium silicate binder, 0.01 part of EVA, 100 parts of water.

[0017] The monofilament diameter of the ceramic fiber is 3-5 μm.

[0018] The inner diameter of the monofilament of the serpentine asbestos is 6-8nm, and the outer diameter is 20-50nm.

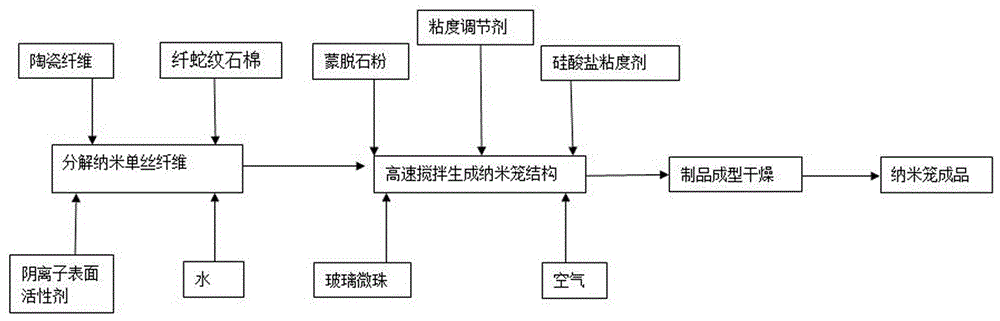

[0019] Add half of the total amount of water to the chrysotile, ceramic fiber and anionic surfactant in the above materials and keep stirring, and under the dual action of mechanical force and anionic surfactant, the chrysotile fiber is evenly decomposed into Nano-scale monofilament fibers, ceramic fibers are also decomposed into independent monofilament fibers; then glass microspheres, montmorillon...

Embodiment 2

[0021] A nano-cage metal high-temperature anti-corrosion and thermal insulation material, which is made of the following raw materials in parts by weight: 10 parts of ceramic fiber, 50 parts of glass microspheres, 15 parts of montmorillonite powder, 20 parts of serpentine asbestos, dodecane 2 parts of sodium phenylsulfonate, 0.2 parts of sodium silicate, 0.2 parts of cellulose ether, and 300 parts of water.

[0022] The monofilament diameter of the ceramic fiber is 3-5 μm.

[0023] The inner diameter of the monofilament of the serpentine asbestos is 6-8nm, and the outer diameter is 20-50nm.

[0024] The preparation method of the nano-cage metal high-temperature anti-corrosion and thermal insulation material in this embodiment is the same as that in Embodiment 1. The maximum service temperature of the material obtained in this example is 650°C, the material density is 198kg / m³, the fire resistance performance is Class A, the waterproof performance is good, the contact with spe...

Embodiment 3

[0026] A nano-cage metal high-temperature anti-corrosion and thermal insulation material is characterized in that it is made of the following raw material ratios by weight: 8 parts of ceramic fiber, 40 parts of glass microspheres, 10 parts of montmorillonite powder, and 15 parts of serpentine asbestos , 1.5 parts of fatty alcohol polyoxyethylene ether sulfate, 0.12 parts of potassium silicate, 0.1 part of polyacrylamide, and 200 parts of water.

[0027] The monofilament diameter of the ceramic fiber is 3-5 μm.

[0028] The inner diameter of the monofilament of the serpentine asbestos is 6-8nm, and the outer diameter is 20-50nm.

[0029] The preparation method of the nano-cage metal high-temperature anti-corrosion and thermal insulation material in this embodiment is the same as that in Embodiment 1. The maximum service temperature of the material obtained in this example is 650°C, the material density is 190kg / m³, the fire resistance performance is Class A, the waterproof per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com