Flame-retardation and heat-insulation material and preparation method thereof

A technology of flame retardant heat preservation and compound flame retardant, which is applied in the field of thermal insulation materials, can solve problems such as unfavorable EPS board applications, achieve increased stability and oxidation resistance, increase flame retardancy and mechanical properties, and increase flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

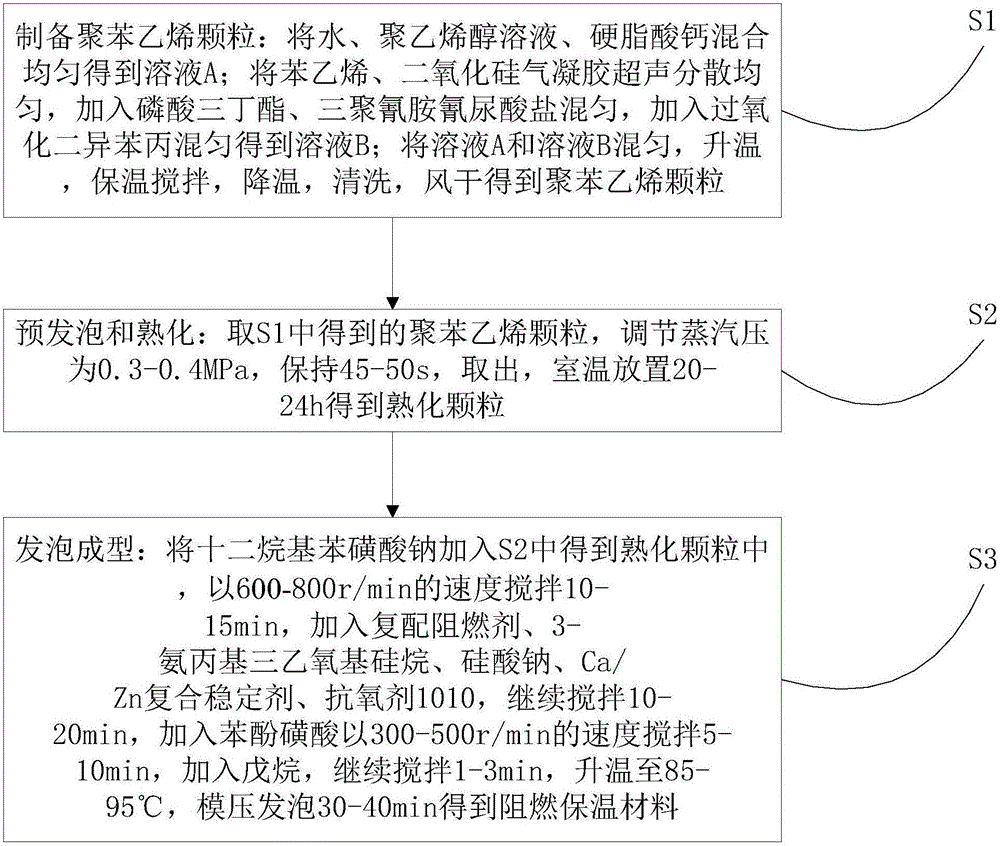

[0022] refer to figure 1 , the preparation method of a kind of flame-retardant insulation material that the present invention proposes, comprises the following steps:

[0023] S1. Preparation of polystyrene particles: Mix water, polyvinyl alcohol solution, and calcium stearate uniformly to obtain solution A; disperse styrene and silica airgel evenly by ultrasonic, add tributyl phosphate, melamine cyanuric acid Mix the salt, add dicumyl peroxide and mix to obtain solution B; mix solution A and solution B, heat up, keep stirring, cool down, wash, and air-dry to obtain polystyrene particles;

[0024] S2. Pre-foaming and curing: Take the polystyrene particles obtained in S1, adjust the vapor pressure to 0.3-0.4 MPa, keep it for 45-50s, take it out, and place it at room temperature for 20-24 hours to obtain mature particles;

[0025] S3. Foam molding: Add sodium dodecylbenzenesulfonate to S2 to obtain mature granules, stir at a speed of 600-800r / min for 10-15min, add compound flam...

Embodiment 1

[0028] A flame-retardant heat-insulating material, the raw materials of which include by weight: 80 parts of styrene, 350 parts of water, 120 parts of polyvinyl alcohol aqueous solution with a mass fraction of 4wt%, 3 parts of calcium stearate, 1.2 parts of tributyl phosphate, melamine 2.4 parts of cyanurate, 4.3 parts of silica airgel, 1.4 parts of dicumyl peroxide, 2.5 parts of sodium dodecylbenzenesulfonate, 10 parts of pentane, 92.7 parts of compound flame retardant, phenol 4 parts of sulfonic acid, 3 parts of 3-aminopropyltriethoxysilane, 20 parts of sodium silicate, 4 parts of Ca / Zn composite stabilizer, 4 parts of antioxidant 1010;

[0029] Among them, the preparation method of the compound flame retardant is: add 10 parts of ammonium polyphosphate, 9.5 parts of magnesium hydroxide, and 3.2 parts of expanded graphite into 70 parts of thermosetting phenolic resin in parts by weight, and stir for 2 hours at a speed of 300r / min. Obtain compound flame retardant.

[0030] T...

Embodiment 2

[0035] A flame retardant heat preservation material, the raw materials of which include by weight: 120 parts of styrene, 200 parts of water, 80 parts of polyvinyl alcohol aqueous solution with a mass fraction of 6 wt%, 6 parts of calcium stearate, 0.8 parts of tributyl phosphate, melamine 3.6 parts of cyanurate, 2 parts of silica airgel, 2.6 parts of dicumyl peroxide, 1.5 parts of sodium dodecylbenzenesulfonate, 18 parts of pentane, 86.3 parts of compound flame retardant, phenol 2 parts of sulfonic acid, 5 parts of 3-aminopropyltriethoxysilane, 10 parts of sodium silicate, 6 parts of Ca / Zn composite stabilizer, 2 parts of antioxidant 1010;

[0036] Among them, the preparation method of the compound flame retardant is: add 15 parts of ammonium polyphosphate, 6.5 parts of magnesium hydroxide, and 4.8 parts of expanded graphite into 60 parts of thermosetting phenolic resin in parts by weight, and stir for 1 hour at a speed of 500r / min. Obtain compound flame retardant.

[0037] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com