A temperature-controlled phase change material microcapsule carrier immobilized enzyme and its preparation method

A phase change material, the technology of immobilizing enzymes, applied in the direction of being immobilized on or in an inorganic carrier, immobilized on/in an organic carrier, etc., can solve the problem of poor thermal stability and cycle stability, narrow working temperature range, etc. problems, to achieve the effect of increased activity recovery rate, low equipment requirements, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

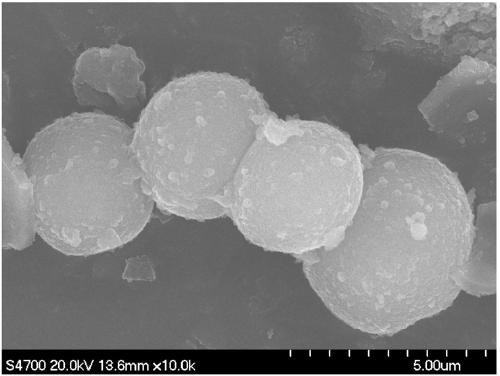

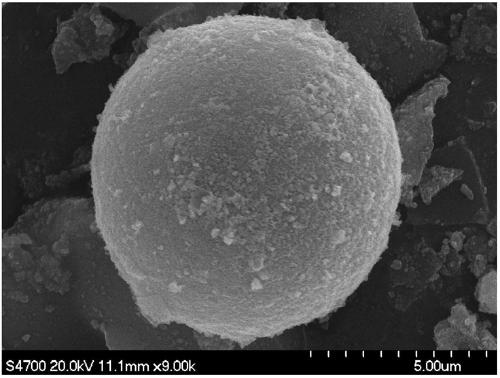

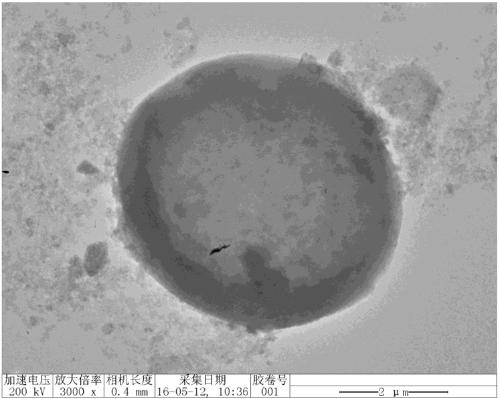

[0039] Step (1): Preparation of temperature-controlled phase change material microcapsule carrier

[0040] First, dissolve 1.0g of ferric chloride hexahydrate and 0.4g of ferrous chloride tetrahydrate in 100mL of deionized water, raise the temperature to 60°C for 5 hours, then adjust the pH to 10 with ammonia water, add 0.1g of dodecane Sodium sulfate, continue to stir for 20min under N 2 Prepare hydrophobic magnetic nanoparticles by reacting under the protection of the atmosphere; add 0.4g magnetic nanoparticles, 5.0g n-eicosane and 5.0g n-butyl titanate into a three-necked flask, and ultrasonicate at 40°C for 30min to make the magnetic nanoparticles and Disperse the titanium source on the surface of the organic phase change material, then add 60mL formamide solution and 0.5g sodium lauryl sulfate and continue to stir for 2h to form a stable emulsion system; prepare a mixture of 1mL deionized water and 40mL formamide, and slowly Add dropwise to the above emulsion system, con...

Embodiment example 2

[0044] Step (1): Preparation of temperature-controlled phase change material microcapsule carrier

[0045] First, dissolve 1.0g of ferric chloride hexahydrate and 0.4g of ferrous chloride tetrahydrate in 100mL of deionized water, raise the temperature to 60°C for 5 hours, then adjust the pH to 10 with ammonia water, add 0.1g of dodecane Sodium sulfate, continue to stir for 20min under N 2 Prepare hydrophobic magnetic nanoparticles by reacting under the protection of the atmosphere; add 0.4g magnetic nanoparticles, 5.0g n-eicosane and 5.0g n-butyl titanate into a three-necked flask, and ultrasonicate at 40°C for 30min to make the magnetic nanoparticles and Disperse the titanium source on the surface of the organic phase change material, then add 60mL formamide solution and 0.5g sodium lauryl sulfate and continue to stir for 2h to form a stable emulsion system; prepare a mixture of 1mL deionized water and 40mL formamide, and slowly Add dropwise in the above-mentioned emulsion s...

Embodiment example 3

[0049] Step (1): Preparation of temperature-controlled phase change material microcapsule carrier

[0050] First, dissolve 1.0g of ferric chloride hexahydrate and 0.4g of ferrous chloride tetrahydrate in 100mL of deionized water, raise the temperature to 60°C for 5 hours, then adjust the pH to 10 with ammonia water, add 0.1g of dodecane Sodium sulfate, continue to stir for 20min under N 2 Prepare hydrophobic magnetic nanoparticles by reacting under the protection of the atmosphere; add 0.4g magnetic nanoparticles, 5.0g n-eicosane and 5.0g n-butyl titanate into a three-necked flask, and ultrasonicate at 40°C for 30min to make the magnetic nanoparticles and Disperse the titanium source on the surface of the organic phase change material, then add 60mL formamide solution and 0.5g sodium lauryl sulfate and continue to stir for 2h to form a stable emulsion system; prepare a mixture of 1mL deionized water and 40mL formamide, and slowly Add dropwise to the above emulsion system, con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com