Method for preparing artificial microenvironment and application thereof

An artificial micro-environment technology, applied in the field of biomedical engineering, can solve problems to be improved, and achieve the effects of convenient application, good plasticity, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

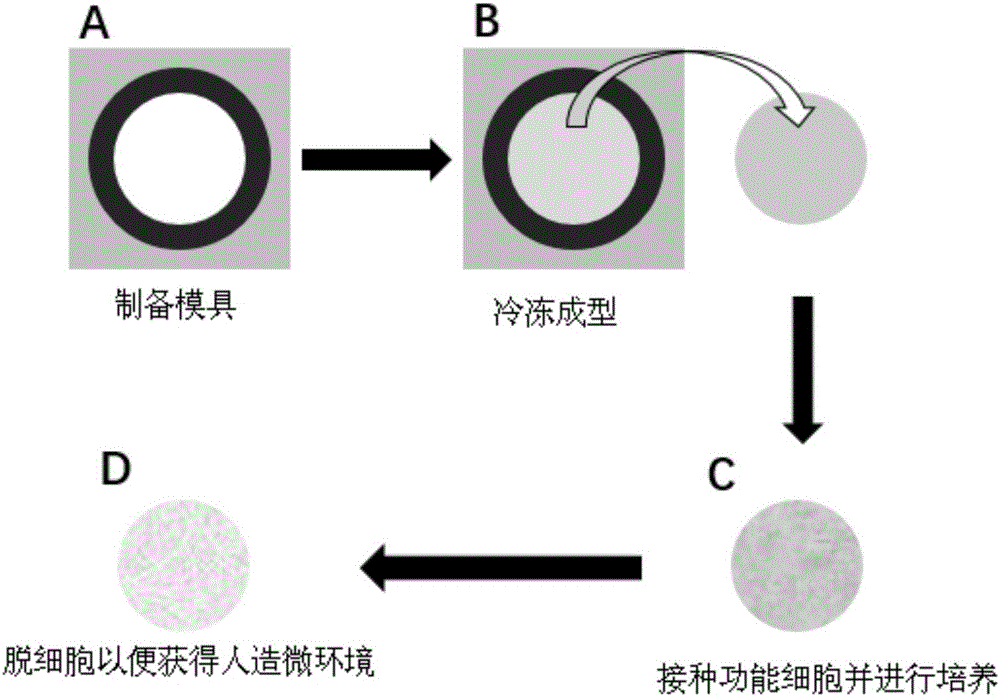

[0082] Example 1. Preparation of three-dimensional porous scaffold and high-throughput scaffold platform by chemical gelation and freeze-drying

[0083] 1. Preparation of three-dimensional porous cell scaffold skeleton

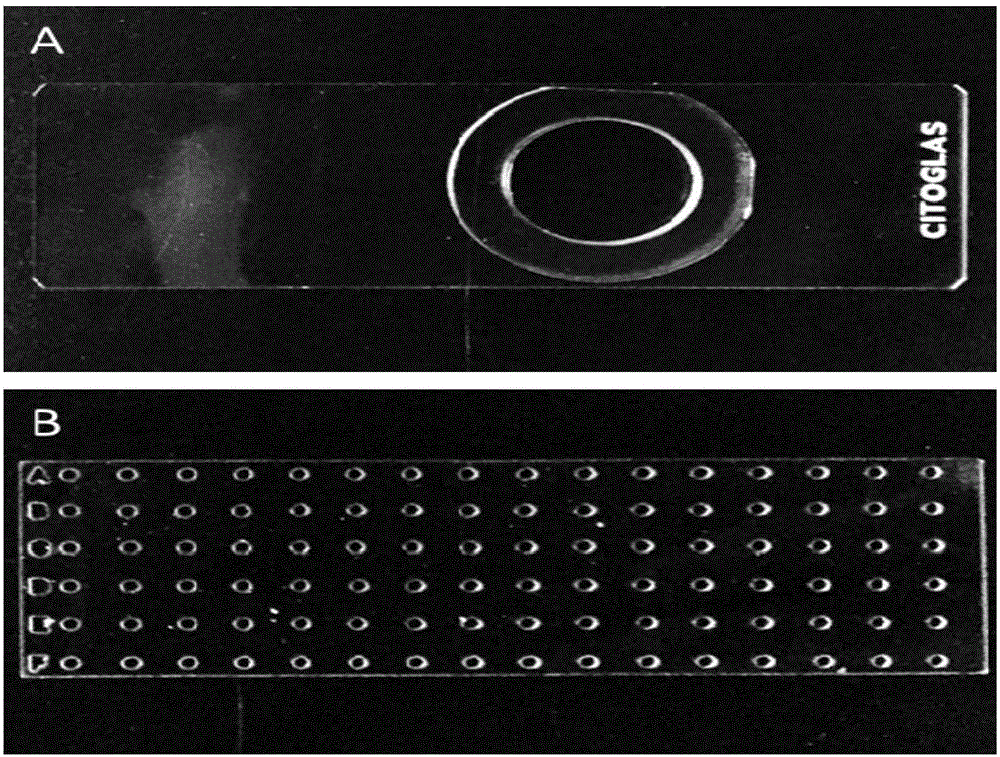

[0084] 1. Laser engraving to prepare the required mold

[0085]A Rayjet laser engraving machine was used to cut polymethyl methacrylate (PMMA) flat plates with thicknesses of 0.3mm, 0.5mm, 1mm, 1.5mm, 2mm, and 3mm (with isolation films attached to both sides) to form mold components. The mold component design is completed by the software AutoCAD, which can be designed into different shapes and sizes according to the needs. For example, in the circular mold, we use a ring with an outer diameter of 5cm and an inner diameter of 2.5cm to realize the circular structure of the pouring material; by changing the shape of the inner ring It can be made into square, triangular and many other shapes of mold components. The main processing parameters of the laser engravi...

Embodiment 2

[0094] Example 2. Functional cells are automatically loaded onto a three-dimensional porous cell scaffold to form a bionic artificial tissue

[0095] The three-dimensional porous cell support of the present invention has good mechanical properties and good water absorption, so cells can be directly absorbed into the support by dropping. In this embodiment, mesenchymal stem cells are taken as an example for illustration.

[0096] 1. Prepare the gelatin three-dimensional porous scaffold according to Example 1.

[0097] 2. Ultraviolet sterilizing the freeze-dried three-dimensional porous scaffold.

[0098] 3. The cells were treated with trypsin and prepared into a single-cell suspension with a certain concentration. Pipette the cell suspension and drop it directly onto the surface of the three-dimensional porous scaffold, and it can be seen that the cell suspension is completely absorbed after a few seconds. Wait 2 hours in a carbon dioxide incubator to allow cells to adhere t...

Embodiment 3

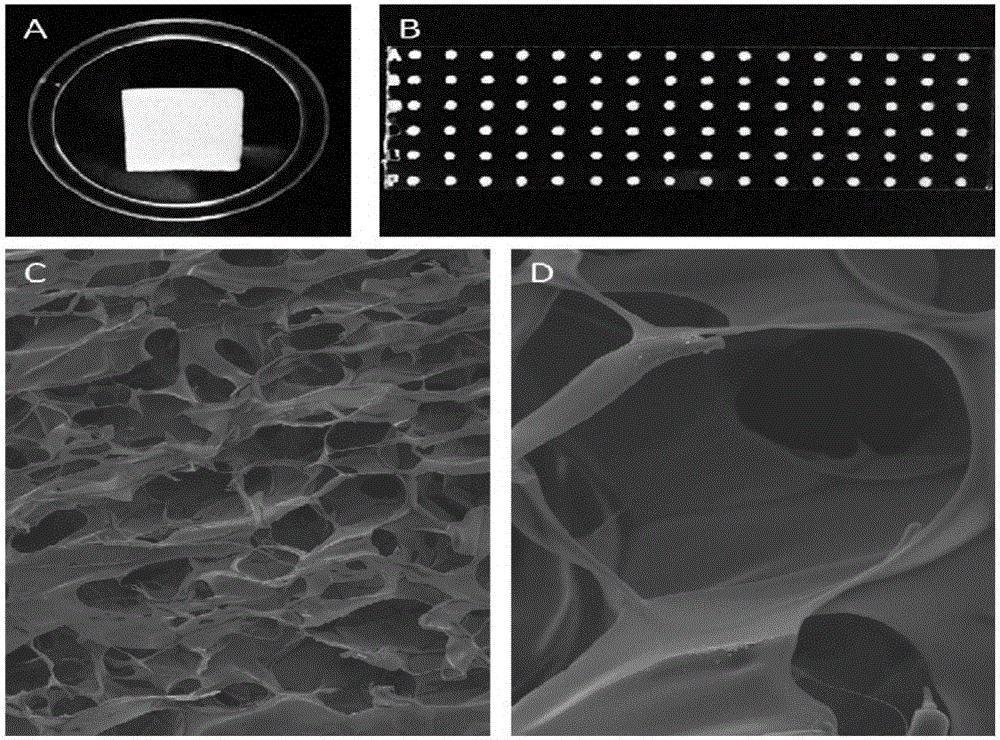

[0100] Example 3. Obtaining free biomimetic microtissues through a high-throughput scaffold platform

[0101] 1. Preparation of special top plate

[0102] The special top plate is made of polydimethylsiloxane (PDMS) by soft etching technology. Take the special top plate corresponding to the high-throughput support platform as an example to prepare: mix PDMS evenly according to the mass ratio of the main agent and the hardener at a ratio of 10:1. The high-throughput mold plate prepared in Example 1 was placed in the pre-made PDMS groove with a depth of 2-3 mm. Pour the bubble-free PDMS mixture into the mold, and ensure that there is a certain thickness of PDMS on the surface of the mold; then place a glass slide on the surface, and then evacuate to the small hole of the mold and there is no gap between the mold and the glass. Air bubbles are present.

[0103] 2. Obtain free three-dimensional porous micro-scaffolds

[0104] After obtaining the prepared miniaturized scaffold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com