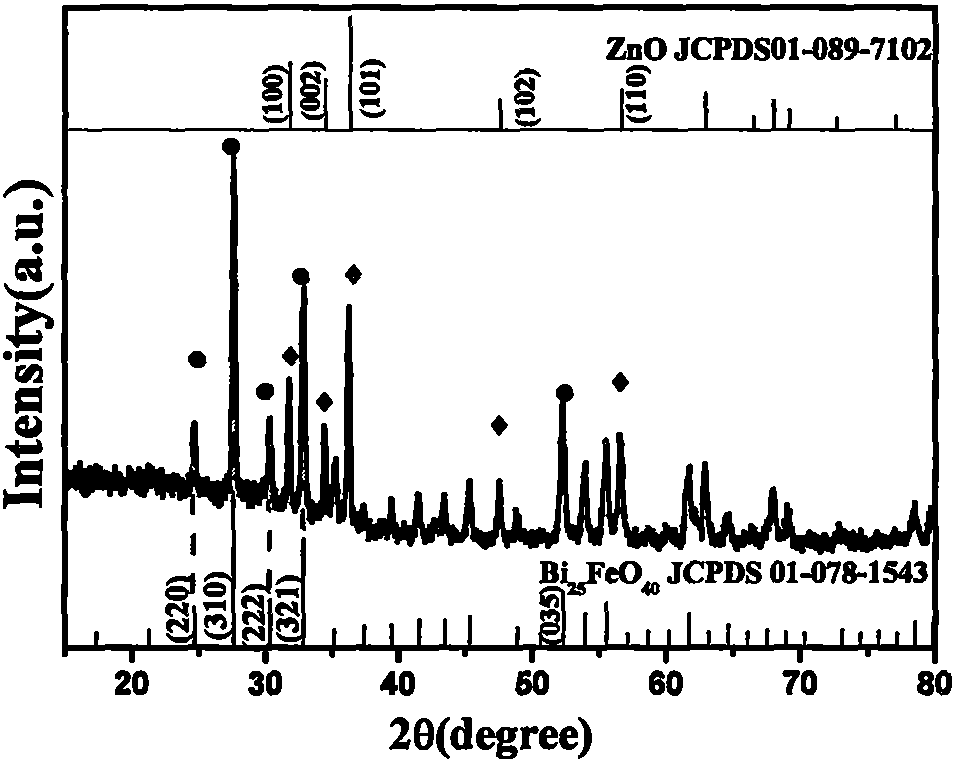

Preparation method for sol-gel one-step low-temperature synthesis of pure-phase Bi25F3O40/ZnO photocatalyst

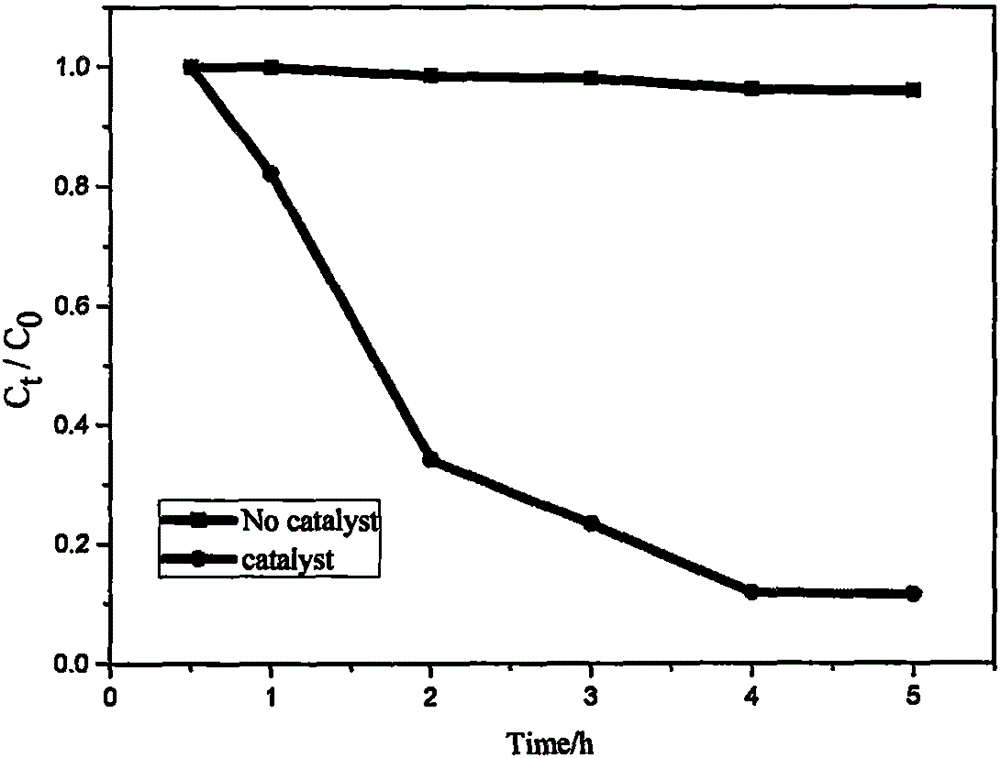

A photocatalyst and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc. problems such as poor stability, to achieve the effects of good catalytic activity and stability, simple preparation method and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment one: the preparation process and steps in this embodiment are as follows:

[0016] (1) Accurately weigh 2.0200g Fe(NO 3 ) 3 9H 2 O, 2.4254g Bi(NO 3 ) 3 ·5H 2 O and 5.9498g Zn(NO 3 ) 2 ·6H 2 O was placed in a beaker, and 100 mL of deionized water was added, and stirred to completely dissolve it. (2) Add 1.1261 g of glycine, maintain magnetic stirring in a constant temperature water bath at 70°C to fully complex, and evaporate to obtain a viscous colloid. (3) Dry the obtained colloid in an air atmosphere at 100 °C for 12 h to obtain a xerogel, and then bake it in a muffle furnace at 500 °C for 3 h to obtain a pure phase Bi 25 FeO 40 / ZnO photocatalyst samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com