High-activity mpg-C3N4/BiVO4/TiO2 heterojunction photocatalyst and preparation method thereof

A mpg-c3n4, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of low photocatalytic activity of a single catalyst, achieve good response, improve Longevity and uniform appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

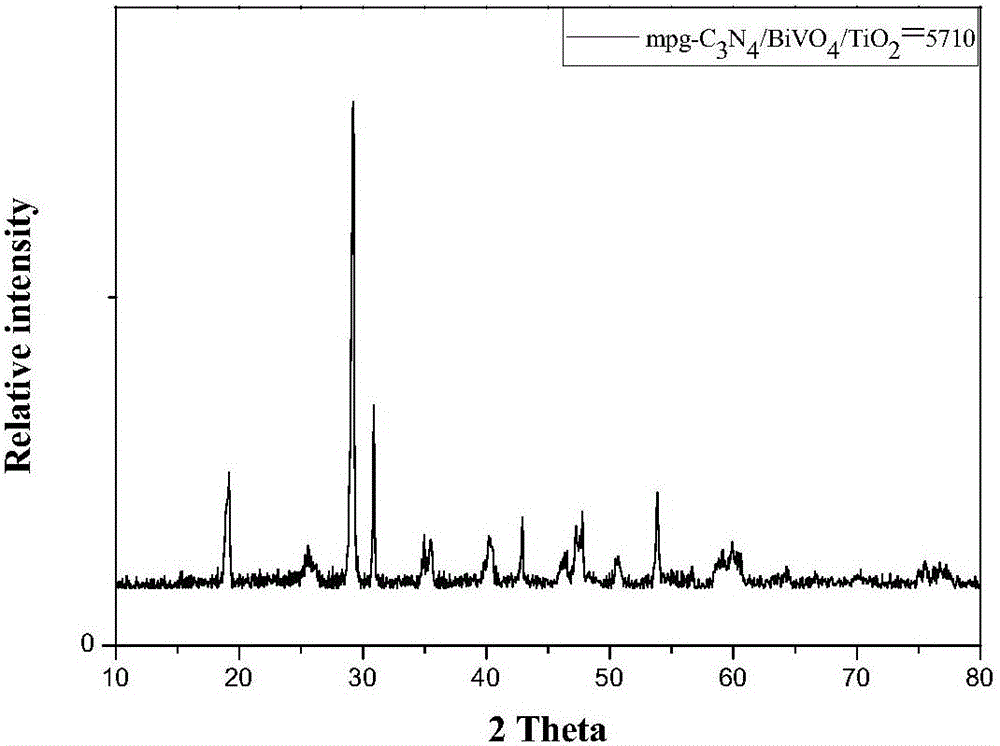

[0027] Dissolve 1g of dicyandiamide in 30ml of water, soak 0.5g of SBA-15 in the solution, and stir at room temperature for 2h. The resulting mixture was dried in an oven at 70°C for 24h to remove moisture, and then calcined at 550°C for 4h under a nitrogen atmosphere with a heating rate of 2.3°C min-1. The sample was stirred in a 2M NH4HF2 solution for 48 hours to remove the template, then centrifuged, washed with water and ethanol three times, and placed in an oven at 70°C to obtain a light yellow powder. Weigh 92mg mpg-C3N4 and disperse it in 35ml deionized water, add 40mg SDBS and 1.4mmol Bi(NO3)3·5H2O, stir to dissolve, then add 1.4mmol NH4VO3 and 2mmol TBOT respectively, and stir at room temperature for 15min. Then the resulting suspension was transferred to a 50ml autoclave containing a polytetrafluoroethylene liner and kept at a constant temperature of 180°C for 20h. After the reactor was naturally cooled to room temperature, it was centrifuged, washed with water, and...

Embodiment 2

[0029] Weigh 18 mg of mpg-C3N4 prepared in Example 1 and disperse it in 35 ml of deionized water, add 40 mg of SDBS and 1.4 mmol of Bi(NO3)3·5H2O and stir to dissolve, then add 1.4 mmol of NH4VO3 and 2 mmol of TBOT in sequence, and stir at room temperature for 15 min. Then the resulting suspension was transferred to a 50ml autoclave containing a polytetrafluoroethylene liner and kept at a constant temperature of 180°C for 20h. After the reactor was naturally cooled to room temperature, it was centrifuged, washed with water, and washed with ethanol three times, and placed in an oven at 70°C to finally obtain a dark yellow mpg-C3N4 / BiVO4 / TiO2=1:7:10 ternary heterojunction photocatalyst. For mpg-C3N4 / BiVO4 / TiO2-1710.

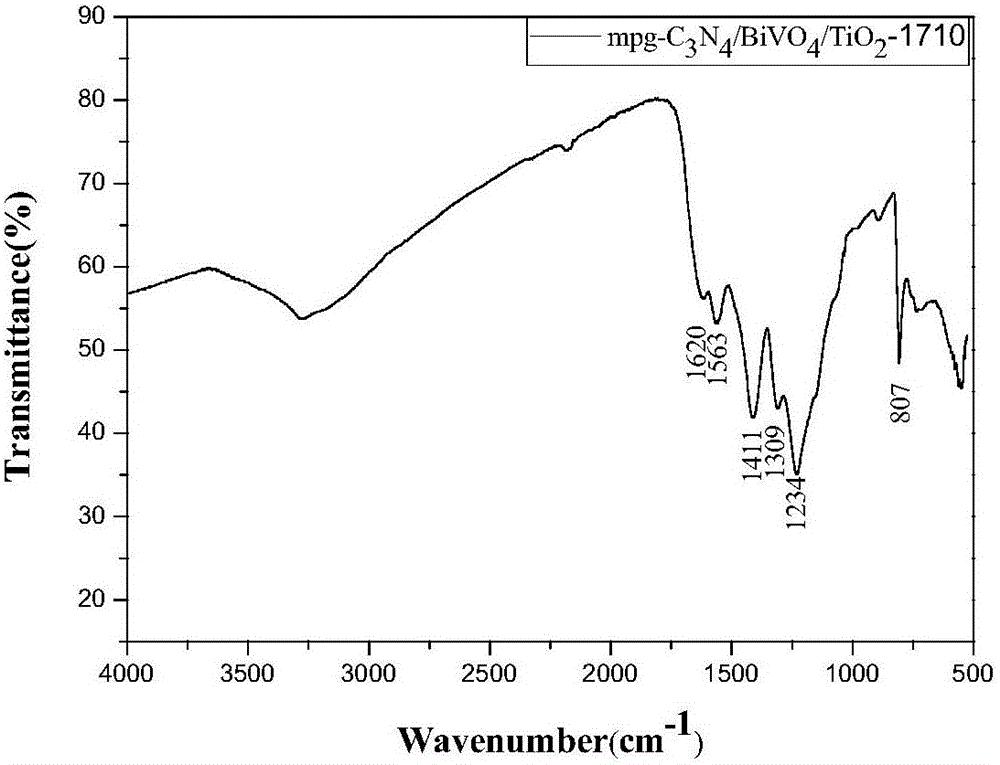

[0030] Carry out FT-IR characterization to the mpg-C3N4 / BiVO4 / TiO2-1710 that embodiment 2 makes, as figure 2 shown. From the infrared spectrum, it is found that the absorption wavelengths at 1620, 1563 and 1411cm-1 are the stretching vibrations of aromatic C-N, ...

Embodiment 3

[0032] Weigh 55 mg of mpg-C3N4 prepared in Example 1 and disperse it in 35 ml of deionized water, add 40 mg of SDBS and 1.4 mmol of Bi(NO3)3·5H2O, stir and dissolve, then add 1.4 mmol of NH4VO3 and 2 mmol of TBOT in sequence, and stir at room temperature for 15 min. Then the resulting suspension was transferred to a 50ml autoclave containing a polytetrafluoroethylene liner and kept at a constant temperature of 180°C for 20h. After the reactor was naturally cooled to room temperature, it was centrifuged, washed with water, and washed with ethanol three times, and placed in an oven at 70°C to finally obtain a dark yellow mpg-C3N4 / BiVO4 / TiO2=3:7:10 ternary heterojunction photocatalyst. For mpg-C3N4 / BiVO4 / TiO2-3710.

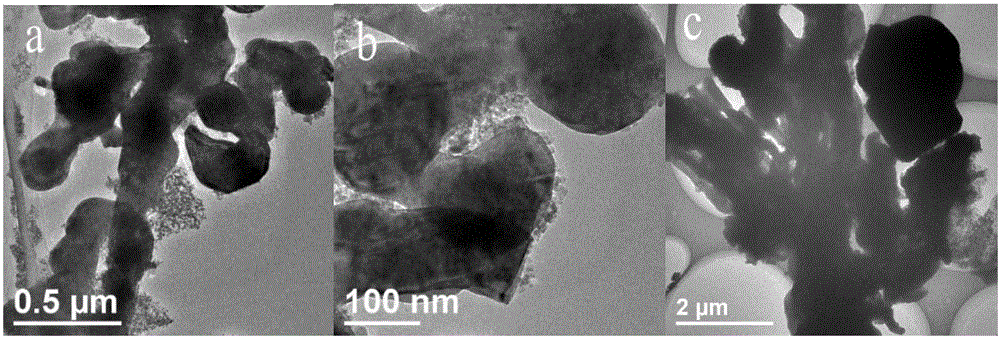

[0033]The mpg-C3N4 / BiVO4 / TiO2-3710 prepared in Example 3 was characterized by TEM. Such as image 3 As shown, Figure a is the hierarchical structure of dendritic bismuth vanadate, and its minimum microstructure unit size is 300nm, which belongs to the submicron str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com