A kind of method for preparing flexible thermal film material

A heat-sensitive thin film and flexible technology, applied in metal material coating process, resistors with negative temperature coefficient, ion implantation plating, etc., can solve the problems of low resistivity, achieve low resistivity, easy process compatibility, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

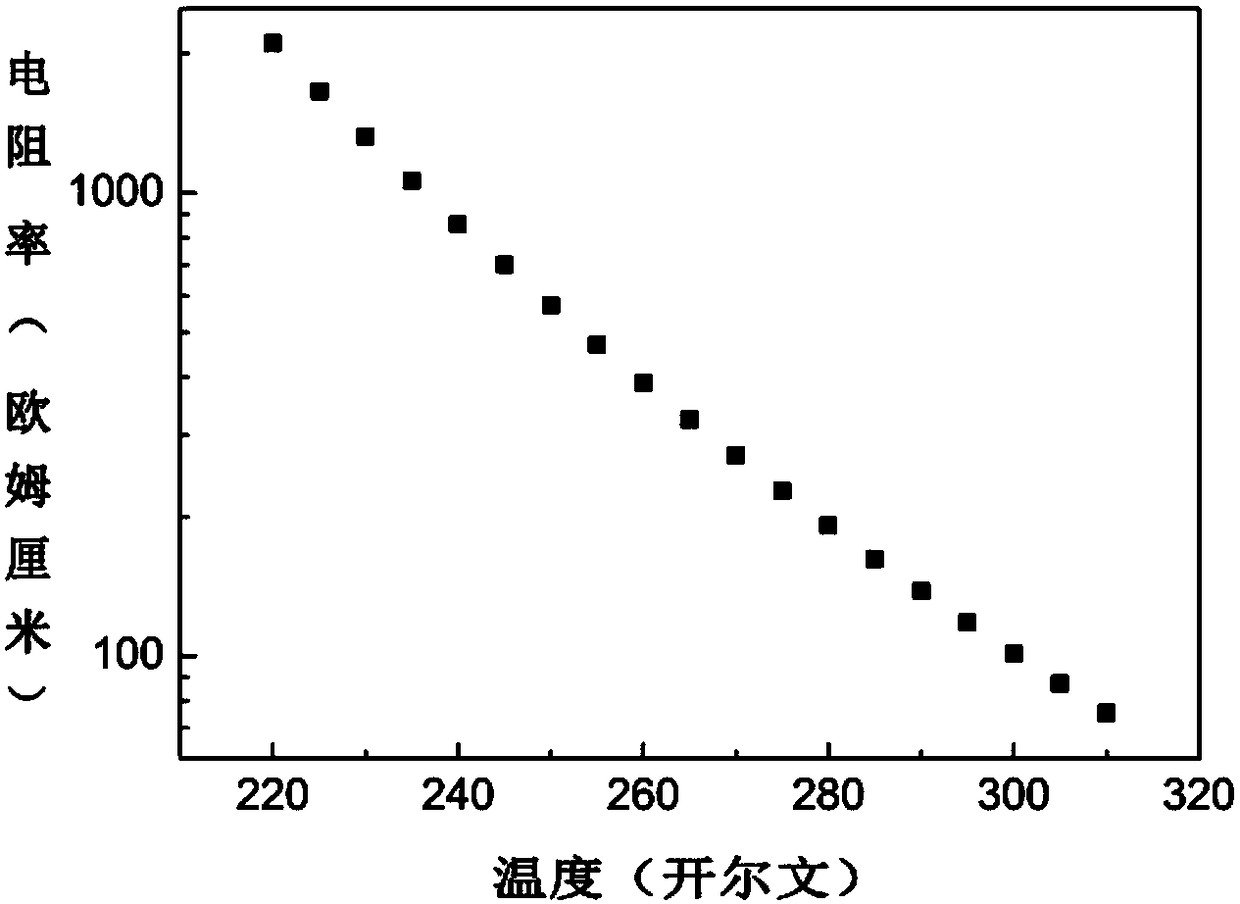

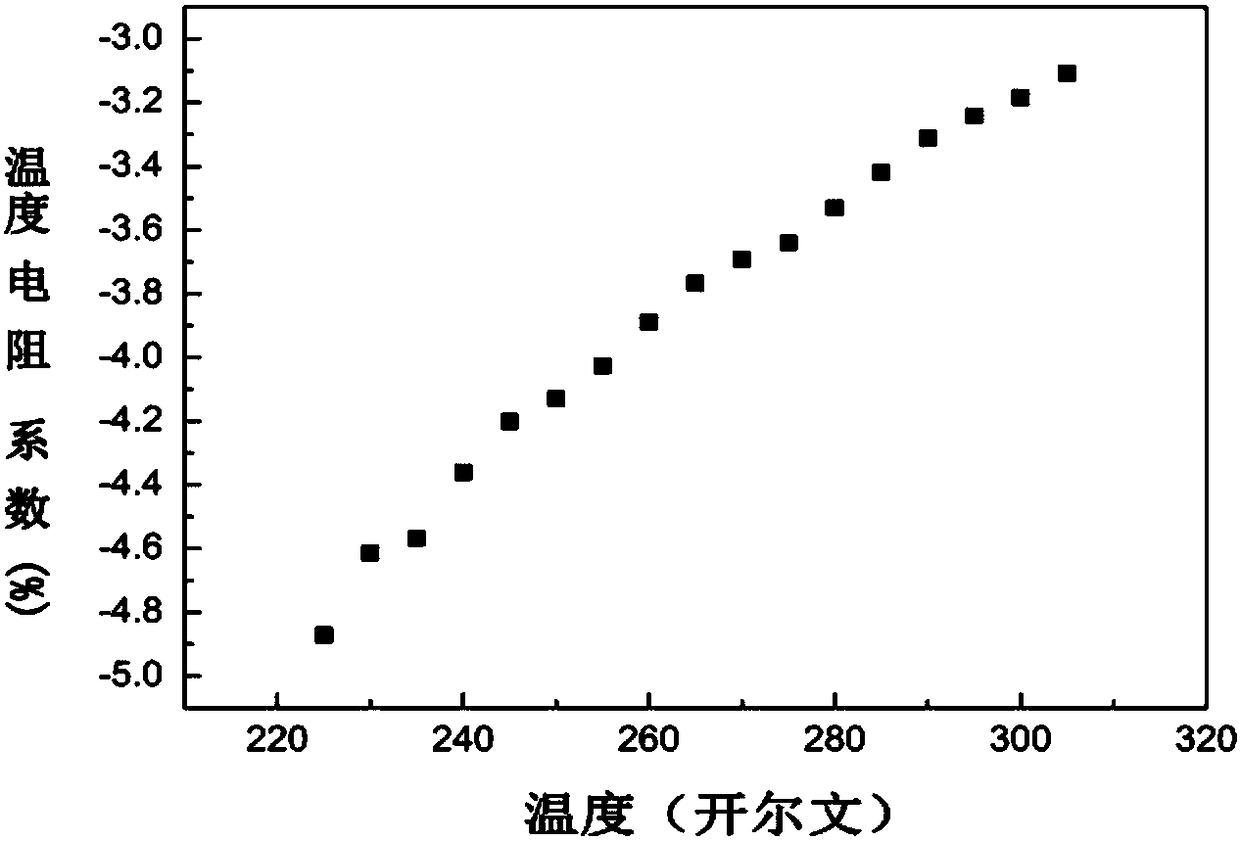

[0022] MnCO with a purity higher than 99.5% is Mn:Co:Ni=13:8:4 according to the atomic ratio of the three metals 3 、Co 2 o 3 、Ni 2 o 3 The powder was fully stirred and mixed, ball milled for 8 hours, sieved, put into an alumina crucible for synthesis, and synthesized at 900°C for 2 hours. Add agate balls and water to the synthesized material, finely grind it for 24 hours, and dry it. The dried powder is added with a binder, and then pre-pressed. Put the embryo body into a high-temperature furnace for sintering at 1170°C for 8 hours. During this period, the furnace maintains an oxygen-rich atmosphere with an oxygen partial pressure of 0.06 MPa, mechanically grinding, cleaning, and drying. Put the prepared target into the magnetron sputtering deposition equipment, vacuum the background to 2E-7Torr, and the gas pressure composition Argon oxygen ratio Ar:O during sputtering 2 =50:1, sputtering pressure 3.7mTorr. An organic flexible substrate sheet of polyethylene terephthal...

Embodiment 2

[0024] MnCO with a purity higher than 99.5% is Mn:Co:Ni=13:8:4 according to the atomic ratio of the three metals 3 、Co 2 o 3 、Ni 2 o 3 The powder was fully stirred and mixed, ball milled for 8 hours, sieved, put into an alumina crucible for synthesis, and synthesized at 900°C for 2 hours. Add agate balls and water to the synthesized material, finely grind it for 24 hours, and dry it. The dried powder is added with a binder, and then pre-pressed. Put the embryo body into a high-temperature furnace for sintering at 1170°C for 8 hours. During this period, the furnace maintains an oxygen-rich atmosphere with an oxygen partial pressure of 0.06 MPa, mechanically grinding, cleaning, and drying. Put the prepared target into the magnetron sputtering deposition equipment, vacuum the background to 2E-7Torr, and the gas pressure composition Argon oxygen ratio Ar:O during sputtering 2 =50:1, sputtering pressure 3.7mTorr. An organic flexible substrate sheet of polyethylene terephthal...

Embodiment 3

[0026] MnCO with a purity higher than 99.5% is Mn:Co:Ni=13:8:4 according to the atomic ratio of the three metals 3 、Co 2 o 3 、Ni 2 o 3 The powder was fully stirred and mixed, ball milled for 8 hours, sieved, put into an alumina crucible for synthesis, and synthesized at 900°C for 2 hours. Add agate balls and water to the synthesized material, finely grind it for 24 hours, and dry it. The dried powder is added with a binder, and then pre-pressed. Put the embryo body into a high-temperature furnace for sintering at 1170°C for 8 hours. During this period, the furnace maintains an oxygen-rich atmosphere with an oxygen partial pressure of 0.06 MPa, mechanically grinding, cleaning, and drying. Put the prepared target into the magnetron sputtering deposition equipment, vacuum the background to 2E-7Torr, and the gas pressure composition Argon oxygen ratio Ar:O during sputtering 2 =50:1, sputtering pressure 10mTorr. An organic flexible substrate sheet of polyethylene terephthala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com